High-gas coal bed group dip orientation drilling cluster and gas extracting method

A technology of gas drainage and directional drilling, which is applied to the layout of gas drainage drilling in high-gas coal seam groups and the field of gas drainage. Release and other issues, to achieve the effect of reducing gas concentration, efficient drainage, and eliminating threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

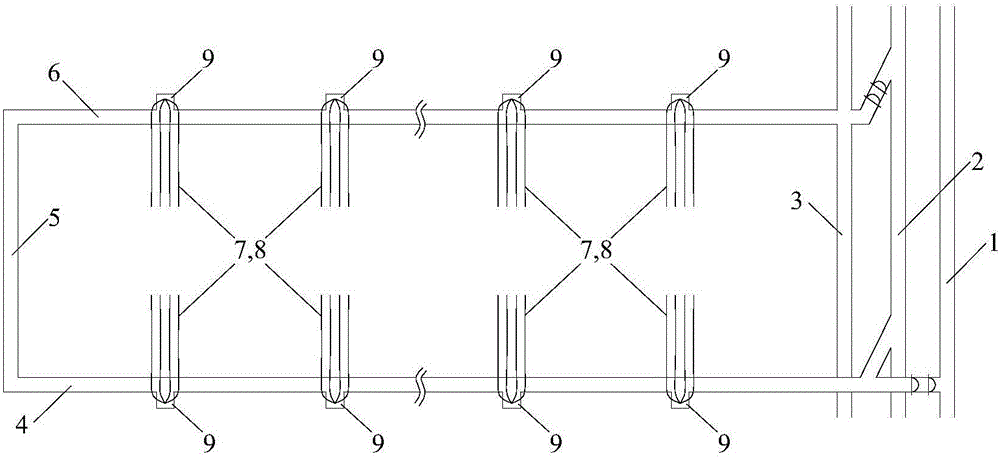

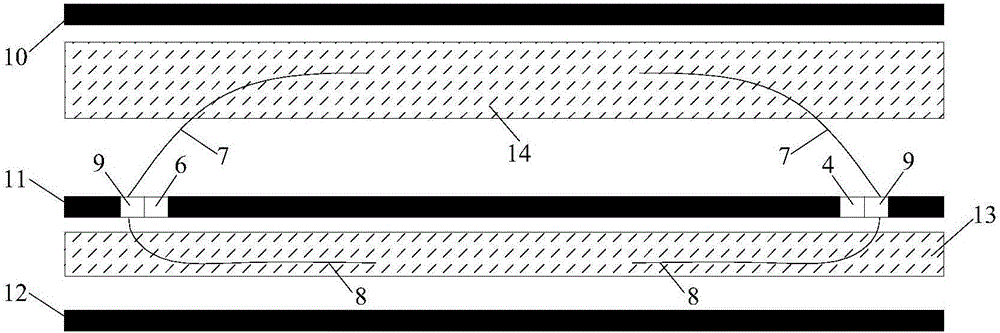

[0012] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1~2 :

[0013] 1) At first, construct a group of drilling sites (9) respectively in the transportation lane (4) and the air return lane (6) of the working face (5) of the coal seam (11), then, in each drilling site (9) respectively The inclined and oriented bendable drilling clusters (7) on the top plate and the inclined and oriented flexible drilling clusters (8) on the bottom plate are constructed. After the drilling construction is completed, the holes are sealed, and gas drainage pipelines are installed in each borehole, and then merged into the The pipelines of the gas drainage system in the air return lane (6) and the transportation lane (4) are used for gas drainage.

[0014] 2) The inclination-oriented bendable drilling clusters (7) on the roof and the inclination-oriented bendable drilling clusters (8) on the bottom plate in each drilling site (9) are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com