Filling mining method for downward access part

A filling mining and route technology, which is applied in underground mining, filling, surface mining, etc., can solve the problems of high mining cost and high filling material consumption, and achieve the effect of reducing mining cost, filling cost and filling ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

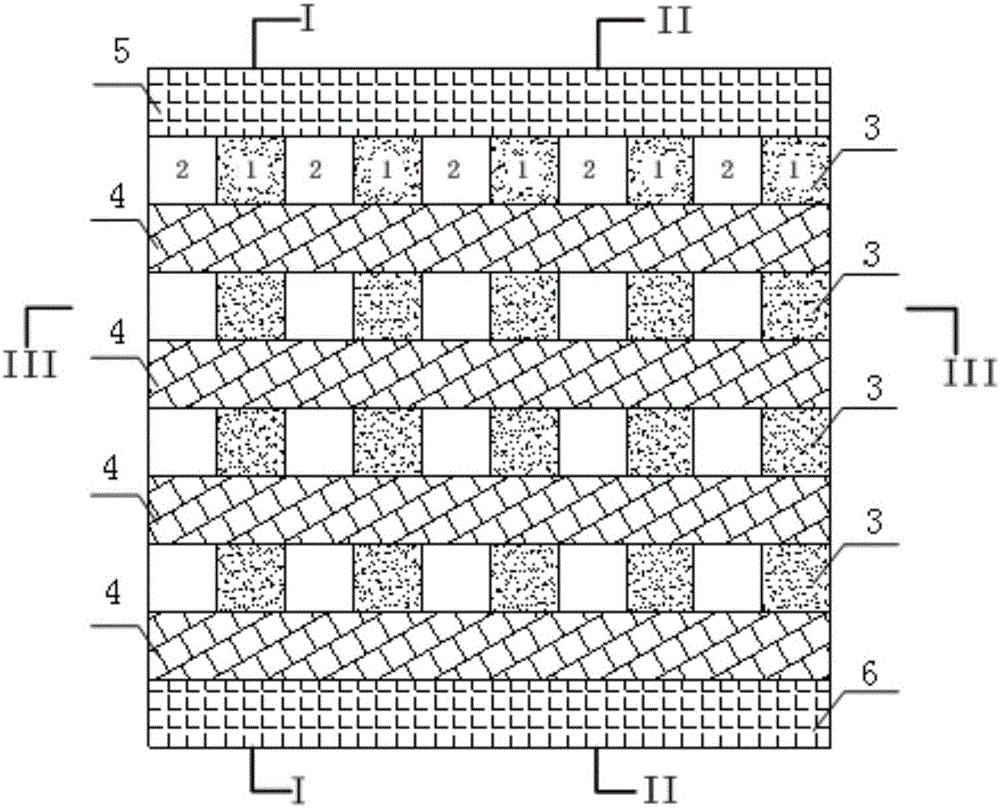

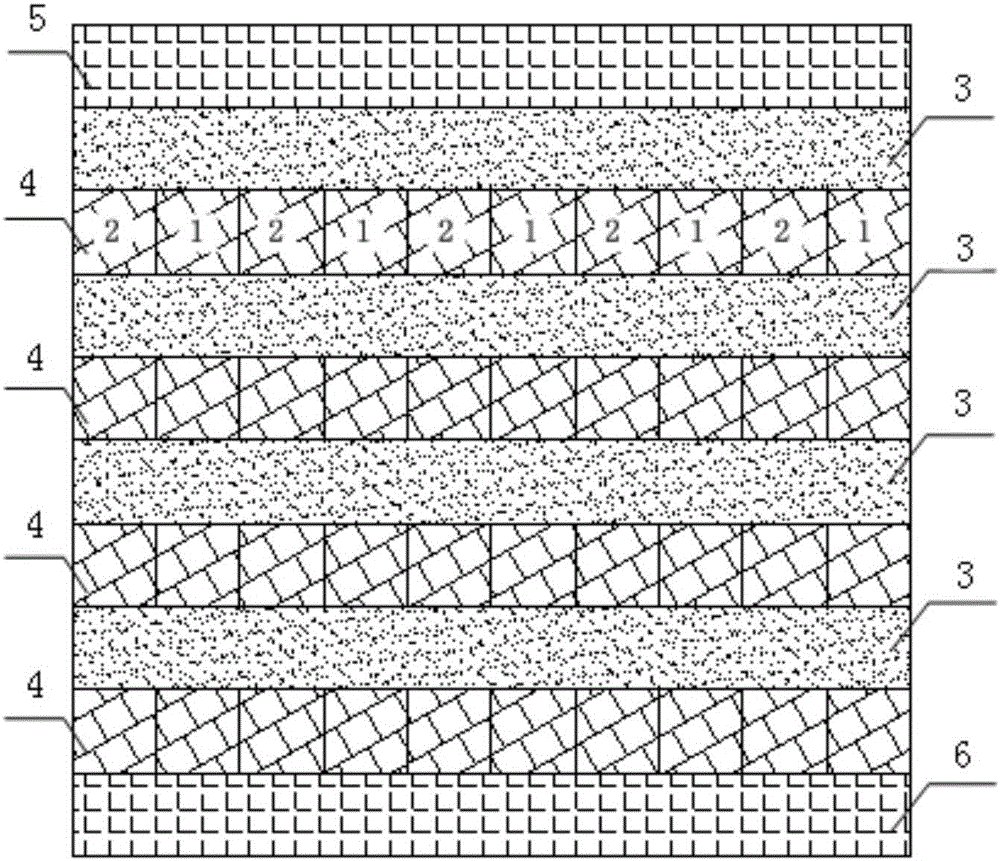

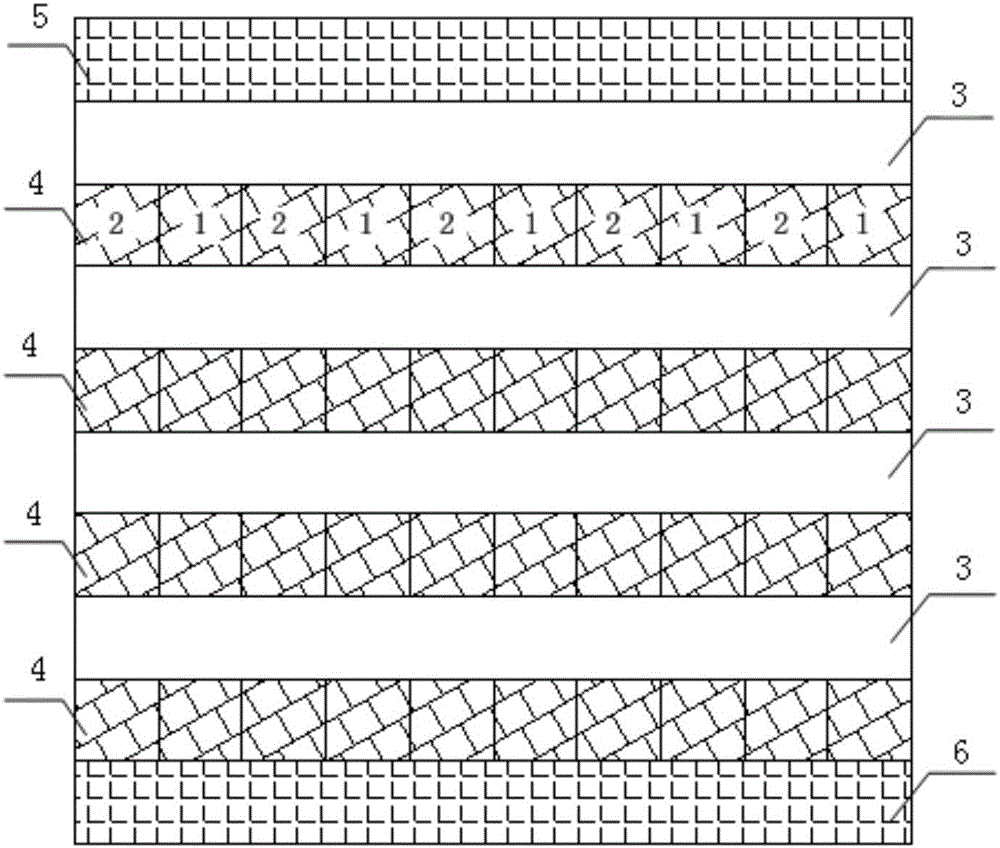

[0022] see figure 1 , figure 2 , image 3 and Figure 4 , a mining method for partial filling of the downward approach, comprising the following steps:

[0023] 1) The ore body mining area is vertically divided into interval filling layer 3 and complete filling layer 4, forming stope roof 5, stope floor 6 and stope surrounding rock 7, interval filling layer 3 and complete filling layer 4 are equal Horizontal layered setting with equal layer heights;

[0024] 2) Divide the interval filling layer 3 and the full filling layer 4 into a number of equal-width and alternately distributed first bars 1 and second bars 2, and the width and layer height of the first bar 1 and the second bar 2 equal;

[0025] 3) The mining sequence in the stope area is mining layer by layer downward, in which the adjacent interval filling layer 3 and the complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com