A kind of prestressed steel frame for building

A technology of prestressed steel bar and prestressed steel, which is applied in the direction of construction, building components, building reinforcements, etc., can solve the problems of being unable to adapt to high-strength construction, concrete components prone to fracture, and unreliable connections between each other. Achieve the effect of being convenient for mass production and use, easy to operate and lift, and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

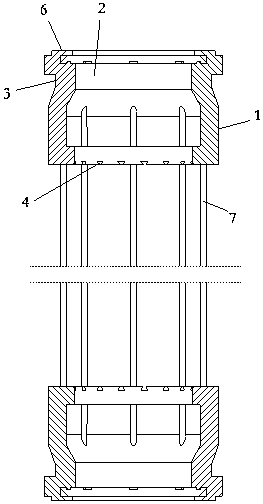

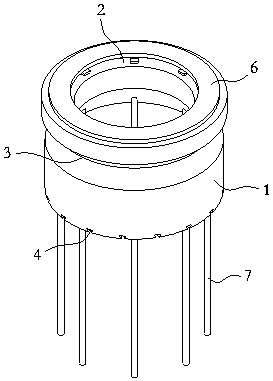

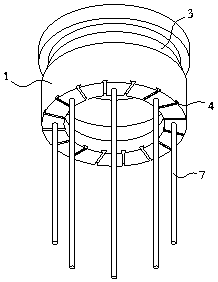

[0014] The following is attached Figures 1 to 4 The given examples further illustrate the specific implementation of the present invention. The present invention is not limited to the description of the following examples.

[0015] Such as Figure 1-4 Shown: a prestressed reinforcement frame for construction, which includes two prestressed steel hoops and a plurality of prestressed steel bars 7 connecting the two prestressed steel hoops.

[0016] Further, the prestressed steel hoop includes a cylindrical tensioning platform 1, a tensioning boss 2 arranged in the middle of the inner side of the tensioning platform 1, and a card slot arranged on the outside of the tensioning platform 1 corresponding to the position of the tensioning boss 2 3 and the welding boss 6 arranged on the top of the tensioning platform 1; when the two reinforcement frames are docked, the welding boss 6 is welded and fixed, and when the two welding bosses 6 are docked, the outer side of the welding bos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com