A prefabricated building wall

A building wall and assembly technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of difficult positioning of unit walls, poor seismic performance of walls, and low construction precision of walls, and achieve good construction quality , Short construction period, easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

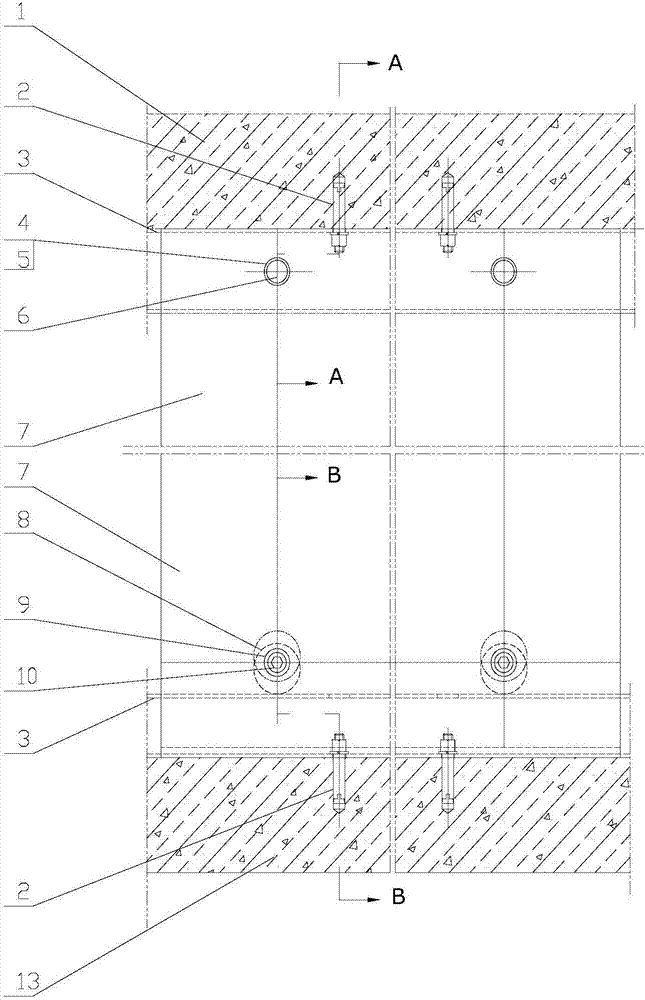

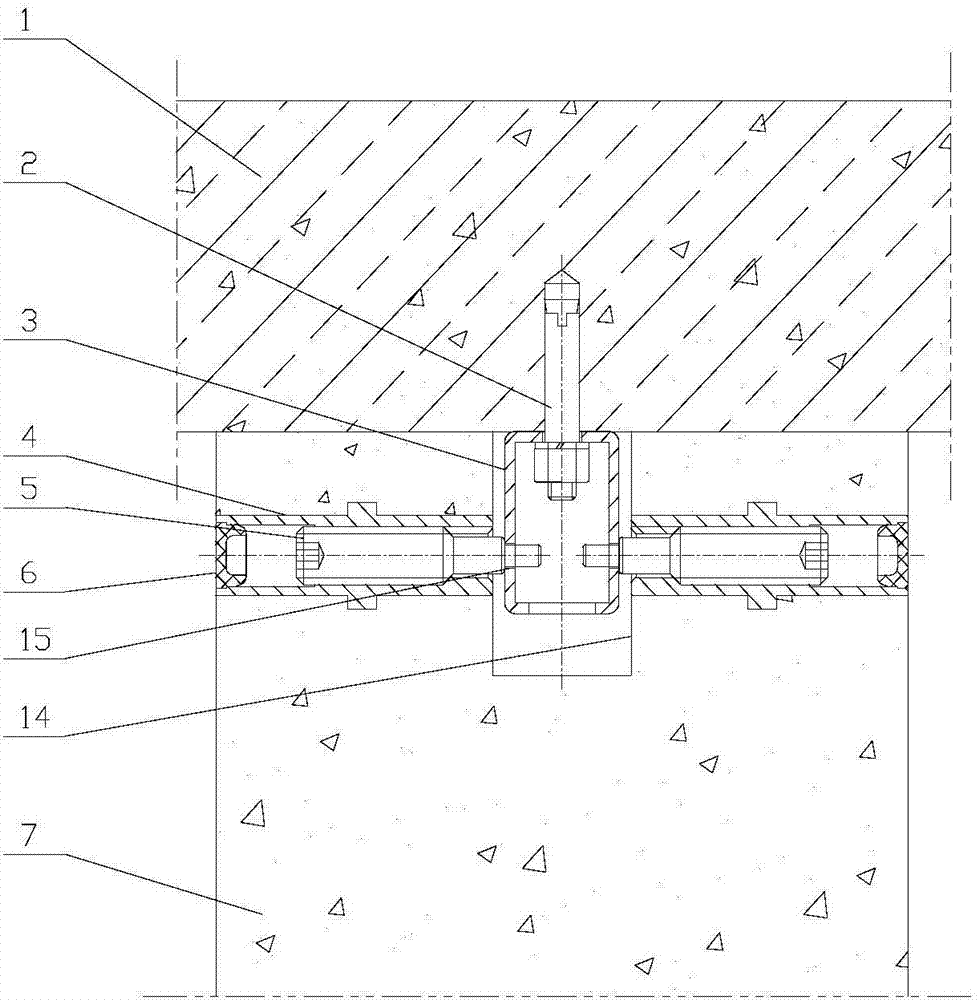

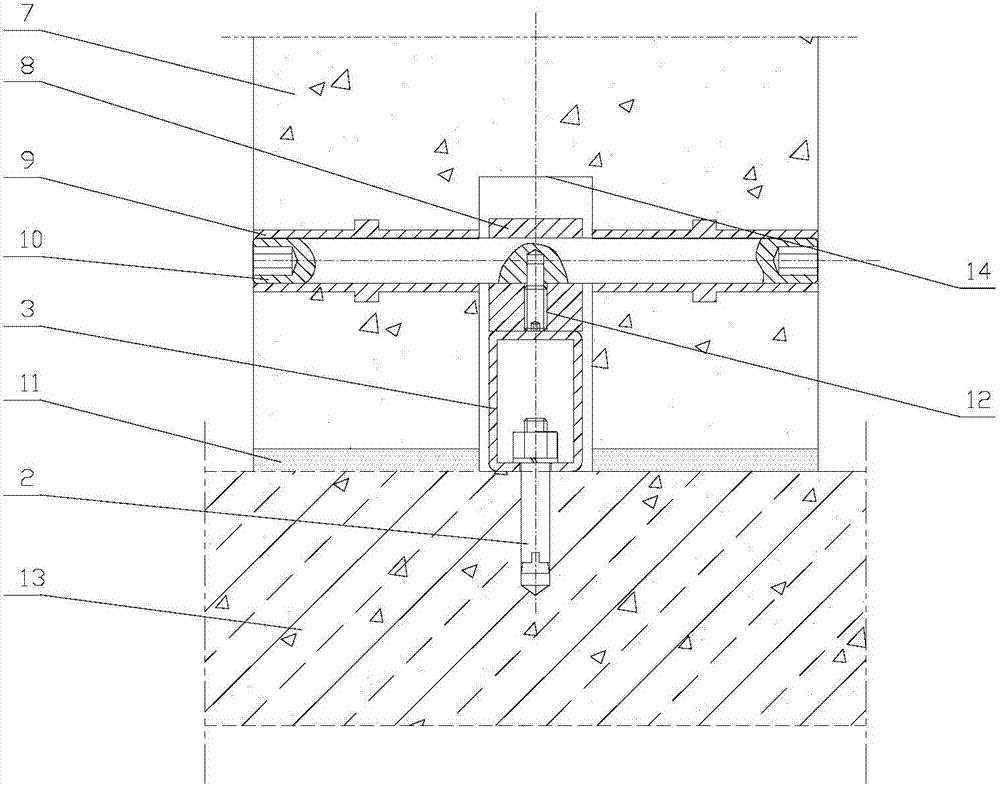

[0016] combine Figure 1 to Figure 3 , The prefabricated building wall of the present invention is composed of a unit wall 7 installed between the upper floor 1 and the lower floor 13 . On the upper floor and the lower floor, use expansion bolts 2 to fix and install the corresponding metal square pipes 3 up and down; The depth is greater than the depth of the upper groove); on both sides of the upper groove of the unit wall, the metal threaded pipe 4 perpendicular to the side of the unit wall is embedded respectively, and the metal threaded pipe is installed in the metal threaded pipe. Set screw 5, the front end of the set screw corresponds to the pre-opened through hole 15 on both sides of the metal square tube, and the front end of the set screw can be inserted into the through hole when the set screw advances; Bury the metal casing 9 perpendicular to the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com