Dredger of improved structure

A technology to improve the structure and dredger, which is applied in the field of ships, can solve the problem that the space of the mud tank cannot be fully utilized, and achieve the effects of reducing direct impact, improving economic benefits, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

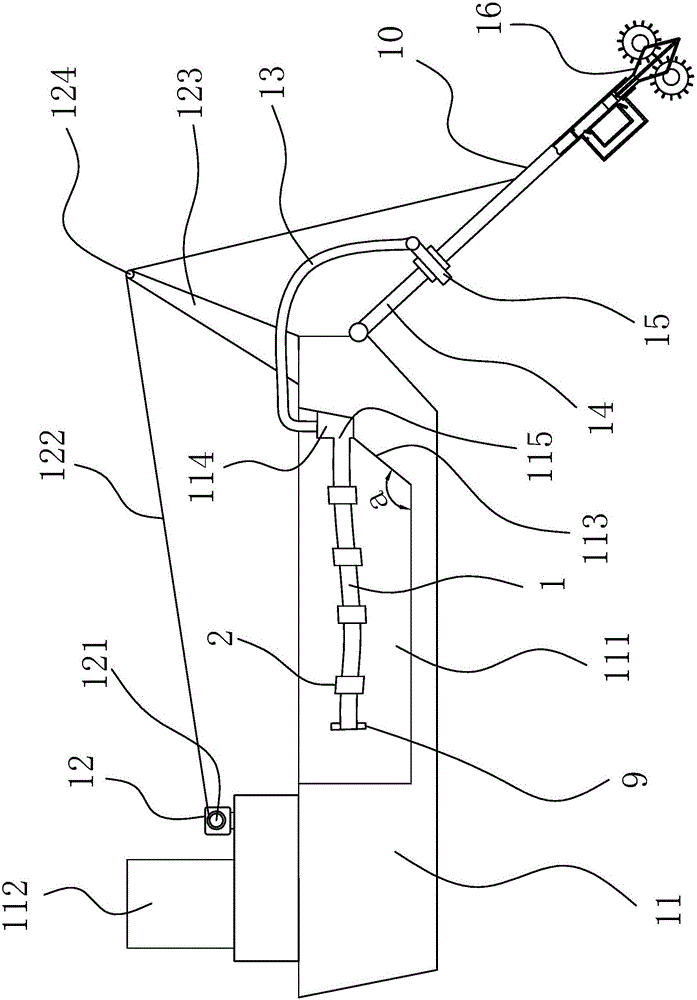

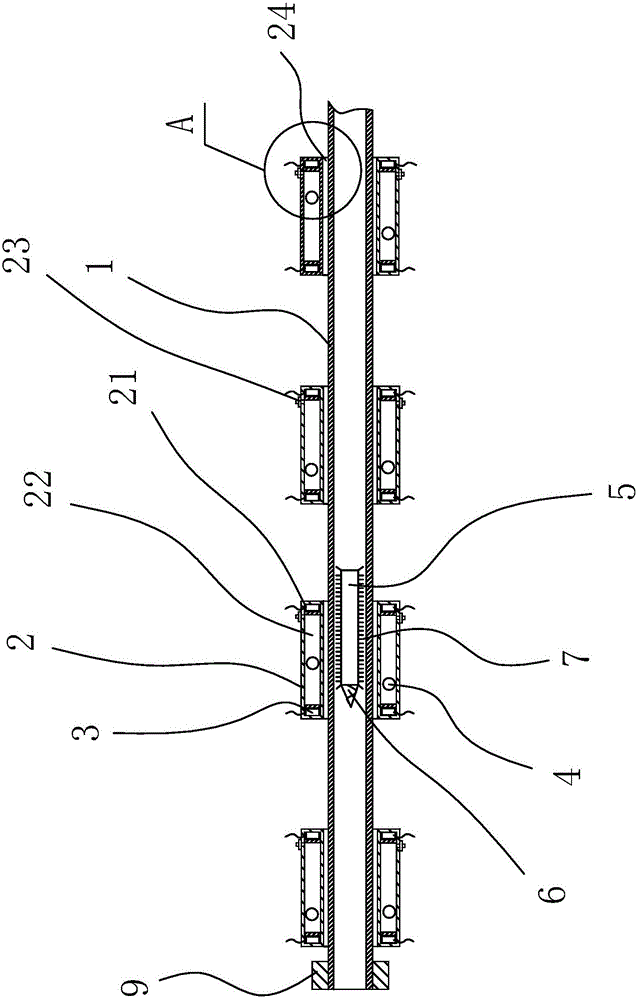

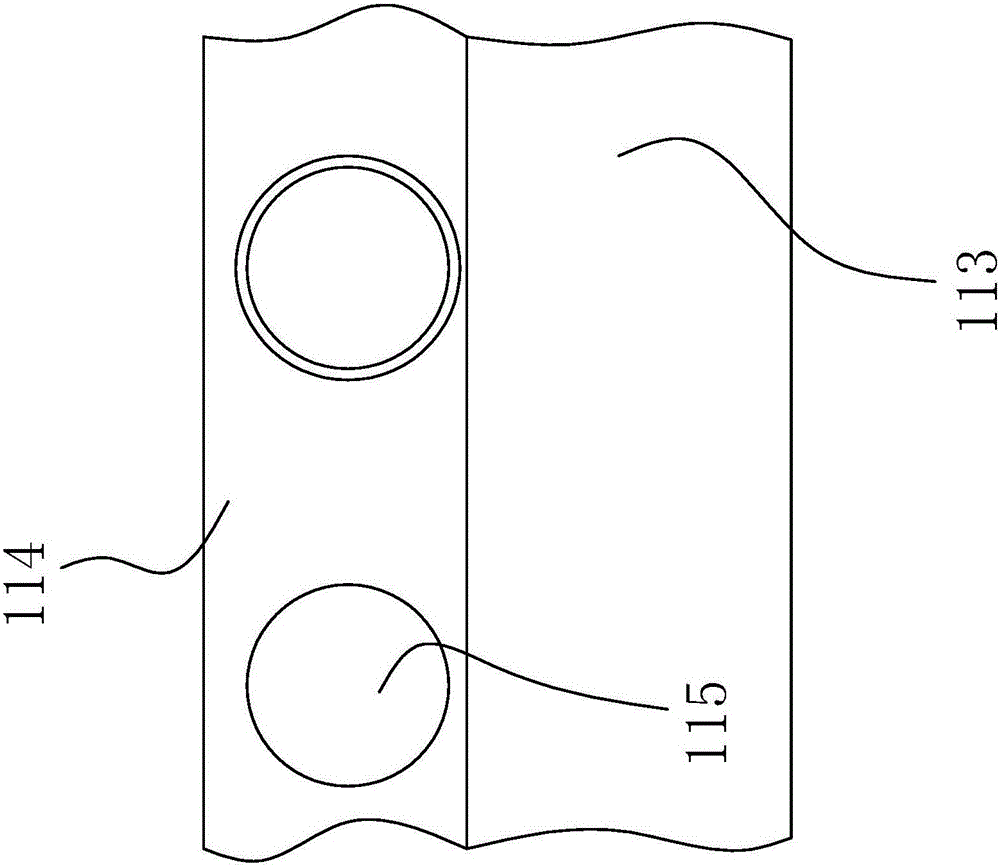

[0037] Such as Figure 1-5 As shown, a dredger with an improved structure includes a hull 11, the inside of the hull 11 has a mud tank 111, and the side of the mud tank 111 near the bow of the hull 11 is provided with an energy dissipation box 114. The side wall of the energy dissipation box 114 is provided with several mud outlets 115, the bow of the hull 11 is hinged with a fixed frame 14, the fixed frame 14 is provided with a dredge pump 15, and the dredge pump 15 The inlet is communicated with one end of the dredging pipe 10, and the other end of the dredging pipe 10 is provided with a silt collecting device 16, and the outlet of the dredging pump 15 is connected with one end of the dredging pipe 13, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com