Three-span anti-node beam-transverse wave-three steel-concrete composite T-shaped continuous beam

A three-steel concrete and antinode technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high production requirements and uneconomical use of ultra-high performance concrete, and achieve material saving, cost reduction, and increased The effect of lateral stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

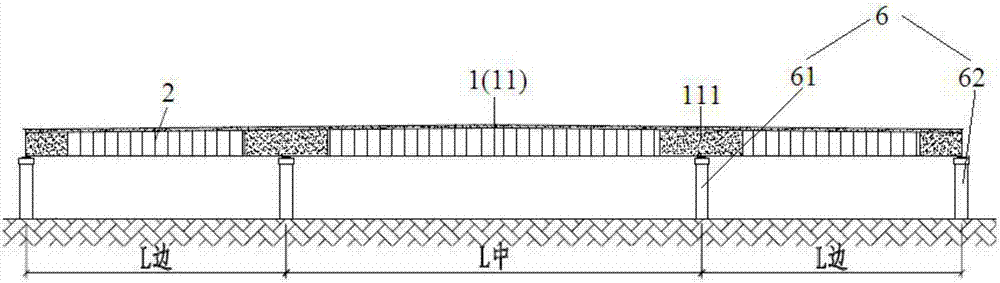

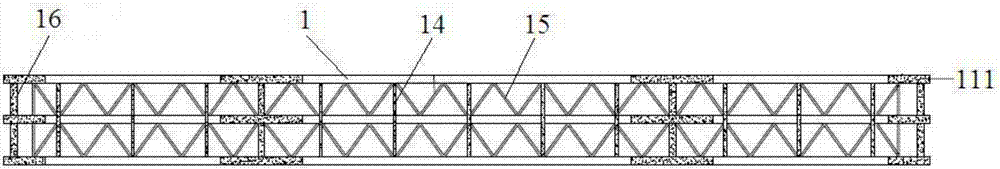

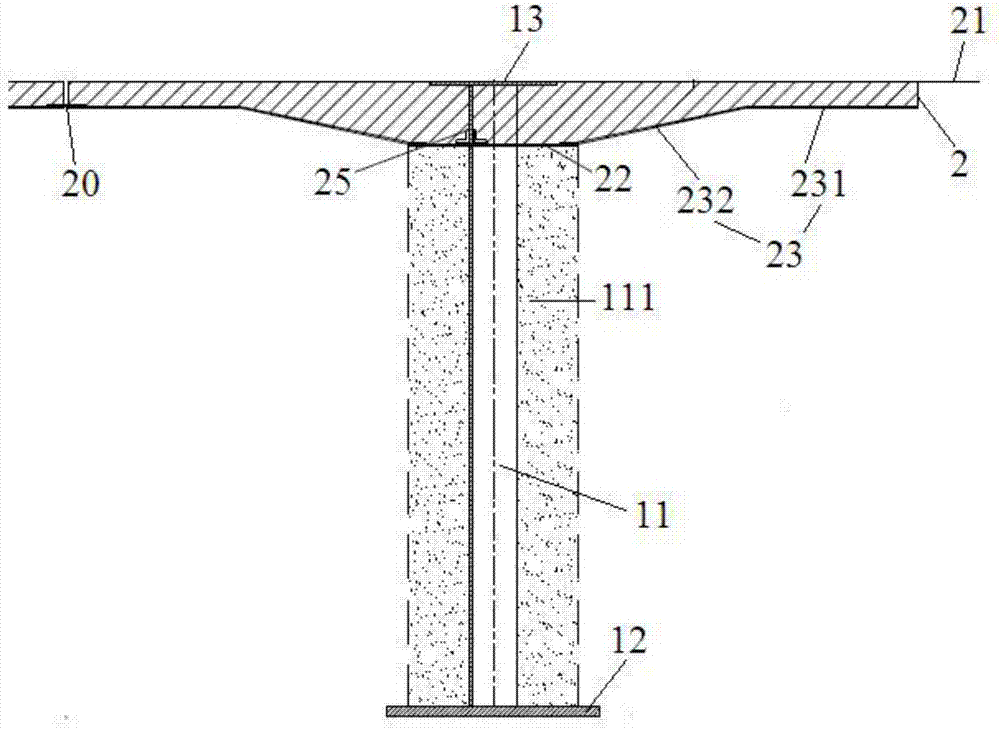

[0049] see figure 1 A kind of three-span antinode engineering beam-transverse wave-three steel concrete composite T-shaped continuous beam of ~Fig. 7:

[0050] In this embodiment, the mid-span span L 中 is 60m, the span L of the two side spans 边 Both are 35m.

[0051] The main girder includes antinode beam 1, steel cross brace 14, steel diagonal brace 15 and concrete diaphragm 16. The wavelength on the corrugated steel web 11 is 160cm, the thickness of the corrugated steel plate is 1.4cm, and the wave height is 22cm. Plate 13 is 2.0cm thick and 60cm wide, and the lower flange plate 12 is 5.0cm thick and 100cm wide. At the bottom of every two antinode beams 1, welded H-shaped steel is used as cross brace 14 and diagonal brace 15, with a width of 30cm and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com