Asphalt milling and planing material distributing machine for asphalt plant mix hot recycling

A technology of thermal regeneration and milling and planing materials, which is applied in the direction of roads, road repairs, roads, etc., can solve the problems of large grading span, material blocking in storage bins, and high cohesiveness, and achieves obvious arch breaking effect and solves material blocking , producing high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

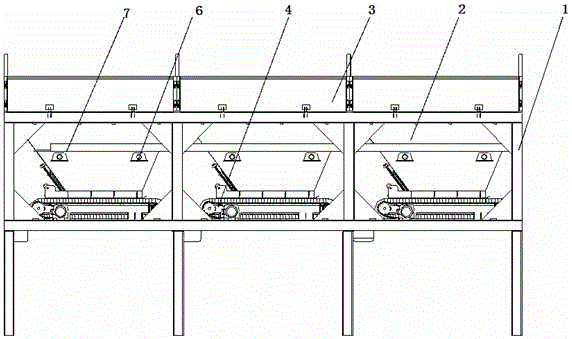

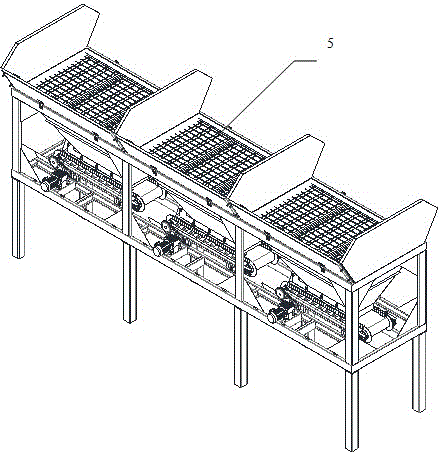

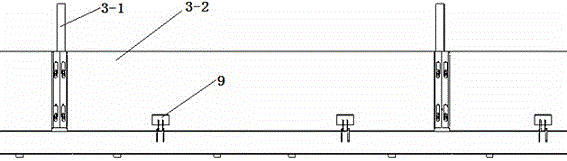

[0023] An asphalt factory mixed heat recycled asphalt milling material batching machine, including a steel structure main body 1, a storage bin 2, a belt scale 4, a vibration device 6 and a pneumatic arch breaking device 7; the steel structure main body 1 is set on a hardened concrete foundation, The top is provided with a baffle plate 3; there are three storage bins 2, which are welded on the main body of the steel structure 1; a screen 5 is installed at the inlet of the storage bin 2 to cooperate with the inlet; the storage bin 2 There is a belt scale 4 at the discharge port, and the belt scale 4 is connected with the steel structure main body 1 by bolts, and an adjustable stopper is also provided at the discharge port 11 of the storage bin 2, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com