Novel drum

A new type of drum technology, applied in small raw hides/large raw hides/leather/fur mechanical processing, small raw hides/large raw hides/leather/fur processing, applications, etc. and other problems to achieve the effect of improving activity efficiency, increasing activity efficiency, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

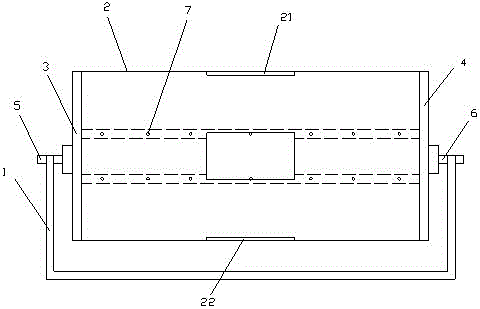

[0014] The present invention as Figure 1-3 As shown, it includes a frame 1 and a hollow drum arranged on the frame 1; the drum includes a cylinder 2 and end caps one 3 and two end caps 4 arranged at both ends of the cylinder, and the cylinder 2 An inlet 21 and an outlet 22 are arranged in the middle, a rotating shaft 1 5 is provided on the outside of the end cover 3, and a rotating shaft 2 6 is provided on the outside of the end cover 2 4, and the rotating shaft 1 and the rotating shaft 2 are respectively arranged on the frame;

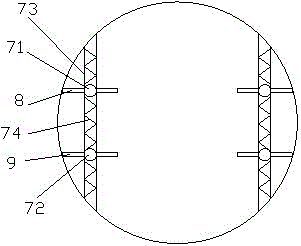

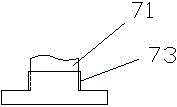

[0015] The two ends of the opposite surfaces of the end cap one and the end cap two are respectively provided with a flexible component 7, and the flexible component includes a slide bar one 71, a slide bar two 72, a chute one 73, a chute two and some springs 74, Described chute one 73 is located at the inner surface of end cap one, and described chute two 4 is located at the inner surface of end cap two, and described chute one corresponds to chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com