Getter composition and device for introducing of mercury into fluorescence lamp for BLU

An introduction device and composition technology, applied in the direction of electric tube/lamp degassing, discharge tube/lamp manufacturing, gas discharge lamp parts, etc., can solve the problems of increased manufacturing cost, serious dust, and inability to maintain mercury release rate, etc. problems, to achieve the effect of improving the working environment and solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

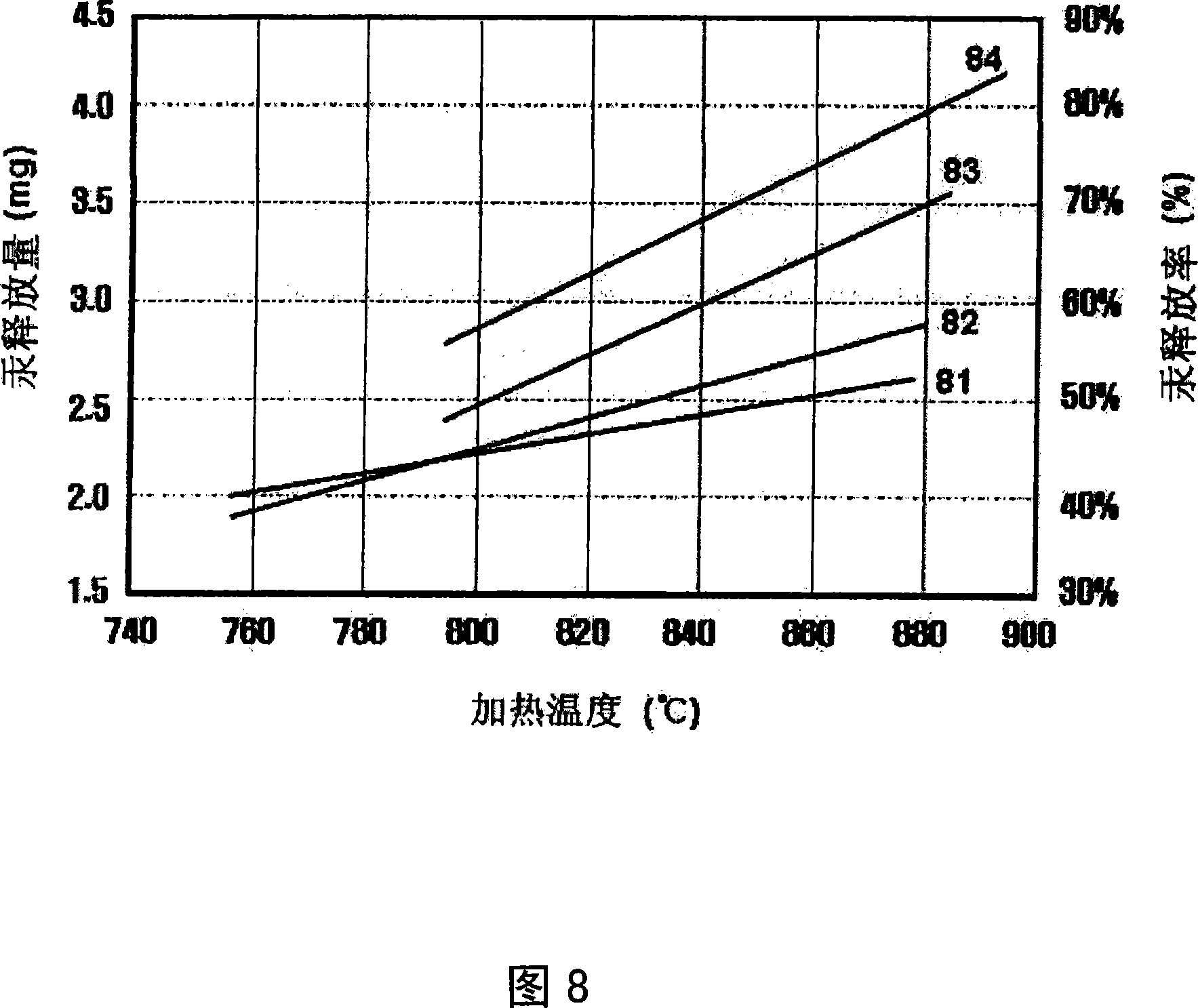

[0066] Example 2 is an example in which the content of Zr and Al was reduced and 2% by weight of Ti was added to the composition of Comparative Example 1. After adding Ti, it can be seen that the mercury release rate is increased by 1% compared with Comparative Example 1.

Embodiment 3

[0067] Example 3 is an example in which 2% by weight of Ta was added to the composition of Example 2. Compared with Example 2, the mercury release efficiency increased by 4% due to the addition of Ta.

[0068] In addition, when comparing Example 1 and Example 3, even in a composition containing 2% by weight of Ta, the mercury release rate can be improved by reducing the Zr and Al contents and adding 2% by weight of Ti.

Embodiment 4

[0069] In Example 4, 1% by weight of Fe was added to the composition of Comparative Example 1. Compared with Comparative Example 1, the mercury release rate of Example 4 was increased by 2%.

[0070]In Examples 5 and 6, 2% by weight of Ta was added to the composition of Comparative Example 1, and a small amount of Fe was added to produce getter compositions. In this case, the mercury release rate was increased by 6-7% compared with Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com