Waterborne nano stealth paint

A nano-invisible technology, applied in coatings, epoxy resin coatings, polyester coatings, etc., can solve problems such as poor light transmission, high coating construction requirements, and inability to meet growing demand, and achieve simple and convenient construction and light transmission. Increased resistance and increased resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

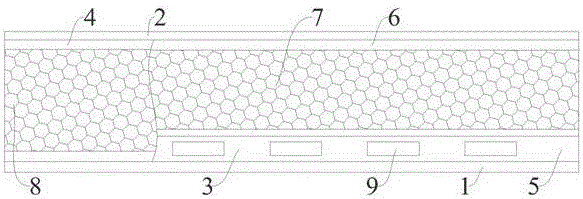

[0013] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0014] figure 1 and figure 2 Shown water-based nano-invisible paint comprises primer 1 and top coat 2, and is fixedly connected with transparent connection bracket 3 between primer 1 and top coat 2, and transparent connection bracket 3 comprises the triangular bottom support 4 that is positioned at the bottom, is positioned at The vertical connecting strips 5 on both sides of the bottom triangular support 4 and the inverted triangle top bracket 6 fixed on the upper end of the vertical connecting strip 5 are fixedly connected to the top bracket 6 for reflecting the surface state of the primer 1 to both sides on the slopes of the top bracket 6. Put reflector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com