Methanol-to-propylene reaction regeneration system and method

A technology of methanol to propylene and reaction regeneration, which is applied in chemical instruments and methods, catalyst regeneration/reactivation, bulk chemical production, etc., can solve the problem of reducing methanol conversion rate, increasing olefin residence time by reaction order, increasing alkanes and aromatics By-products and other problems, to avoid hydrogen transfer reaction, increase the inlet concentration, reduce the generation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

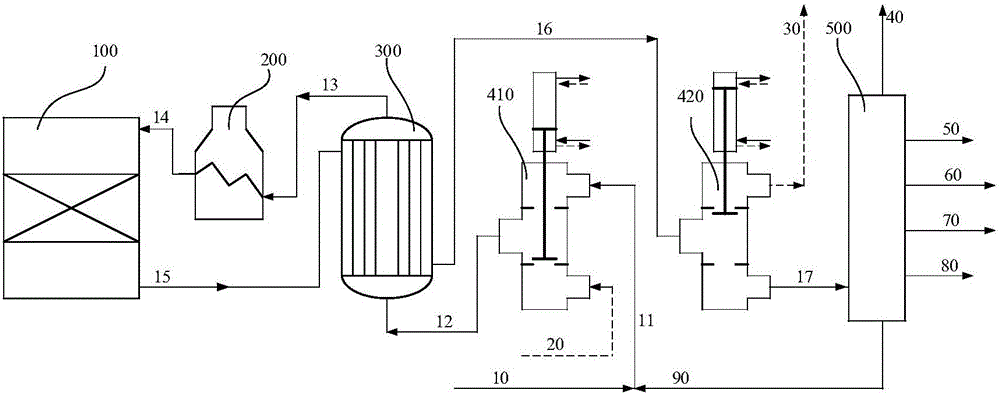

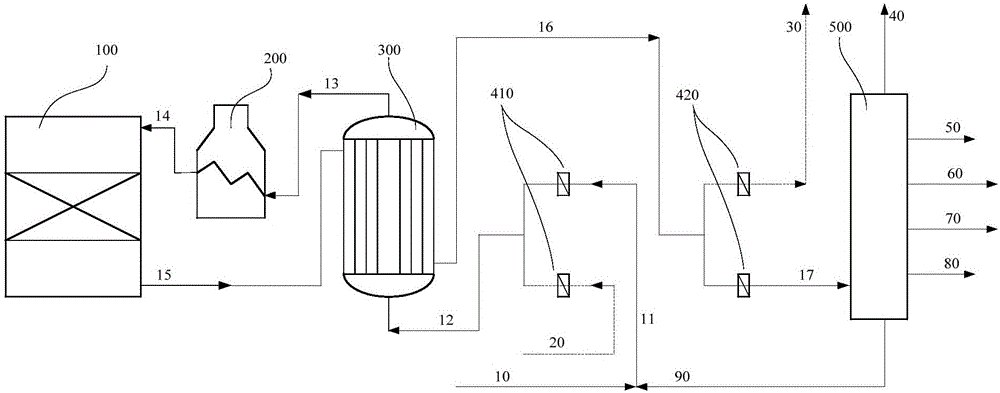

[0070] Such as figure 1 As shown, a methanol-to-propylene reaction regeneration device includes an inlet stream switching valve 410, a tubular heat exchanger 300, a heating furnace 200, a single-stage fixed-bed reactor 100, and an outlet Stream switching valve 420 and separation unit 500. The reactor 100 is filled with 50 tons of catalyst, the catalyst is HZSM-5 type molecular sieve particles, and the Si / Al ratio is 200. Methanol raw material 10 flow rate is 200 tons / hour; Recirculating stream is the mixture of water and hydrocarbon, and flow rate is water 252 tons / hour, C 2 and C 4 -C 6 Hydrocarbon 775 tons / hour. After heat exchange and furnace heating, the temperature of reactant stream 14 is 400°C. After the reaction, the temperature of the reactant stream 15 was 480° C., and the conversion rate of methanol was 99%. After separation, the output of propylene 60 is 76.6 tons / hour, which is equivalent to a selectivity of 87.54% for propylene, 3 tons / hour for fuel gas and...

Embodiment 2

[0073] Such as figure 1As shown, a methanol-to-propylene reaction regeneration device includes an inlet stream switching valve 410, a tubular heat exchanger 300, a heating furnace 200, a single-stage fixed-bed reactor 100, and an outlet Stream switching valve 420 and separation unit 500. Reactor 100 is filled with 50 tons of catalyst, which is ZSM-5 high-silicon molecular sieve particles, and the silicon-aluminum ratio is the same as that in Example 1. Methanol raw material 10 flow rate is 100 tons / hour; Recycle flow is the mixture of water and hydrocarbon, and flow rate is water 126 tons / hour, C 2 and C 4 -C 6 Hydrocarbon 387 tons / hour. After heat exchange and furnace heating, the temperature of reactant stream 14 is 400°C. After the reaction, the temperature of the reactant stream 15 was 480° C., and the conversion rate of methanol was 99.9%. After separation, the output of propylene is 35.6 tons / hour, which corresponds to a selectivity of propylene of 81.37%, 3.5 tons...

Embodiment 3

[0076] Such as figure 1 As shown, a methanol-to-propylene reaction regeneration device includes an inlet stream switching valve 410, a tubular heat exchanger 300, a heating furnace 200, a single-stage fixed-bed reactor 100, and an outlet Stream switching valve 420 and separation unit 500. Reactor 100 is filled with 50 tons of catalyst, which is ZSM-5 high-silicon molecular sieve particles, and the silicon-aluminum ratio is the same as that in Example 1. Methanol raw material 10 flow rate is 400 tons / hour; Recycle flow is the mixture of water and hydrocarbon, and flow rate is water 504 tons / hour, C 2 and C 4 -C 6 Hydrocarbon 1548 tons / hour. After heat exchange and furnace heating, the temperature of reactant stream 14 is 400°C. After the reaction, the temperature of the reactant stream 15 was 480° C., and the conversion rate of methanol was 97%. After separation, the output of propylene is 161 tons / hour, which corresponds to a selectivity of 92.0% for propylene, 5.5 tons / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com