Electric arc furnace cover casting material, electric arc furnace cover and production method of electric arc furnace cover

A technology of electric arc furnace and castable, which is applied in the field of electric arc furnace steelmaking equipment, and can solve the problems of poor medium and high temperature strength, corrosion resistance and thermal shock, affecting the normal production and operation of electric arc furnace, and missing edges and corners of the electric arc furnace cover. , to achieve high corrosion resistance, improve work efficiency and benefits, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

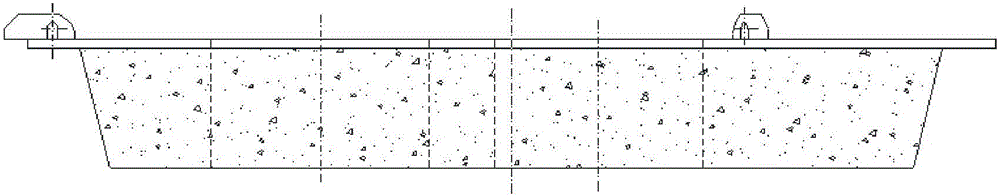

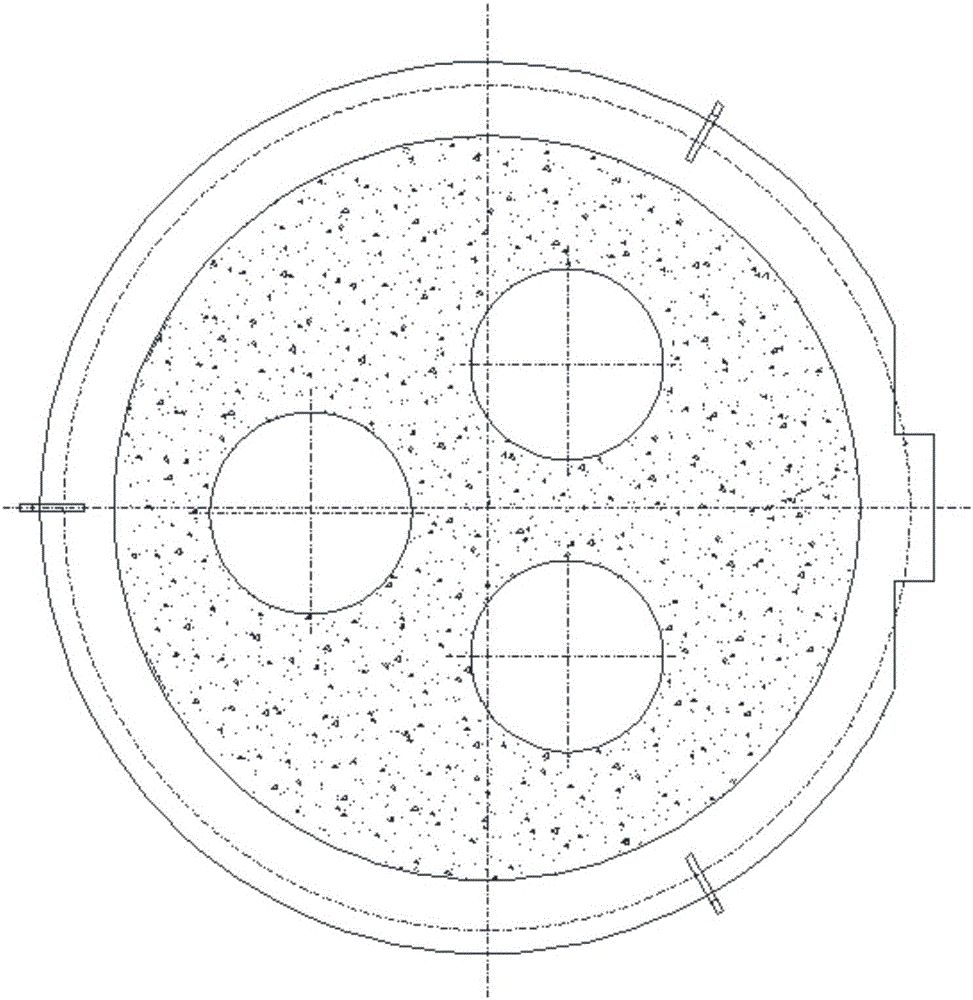

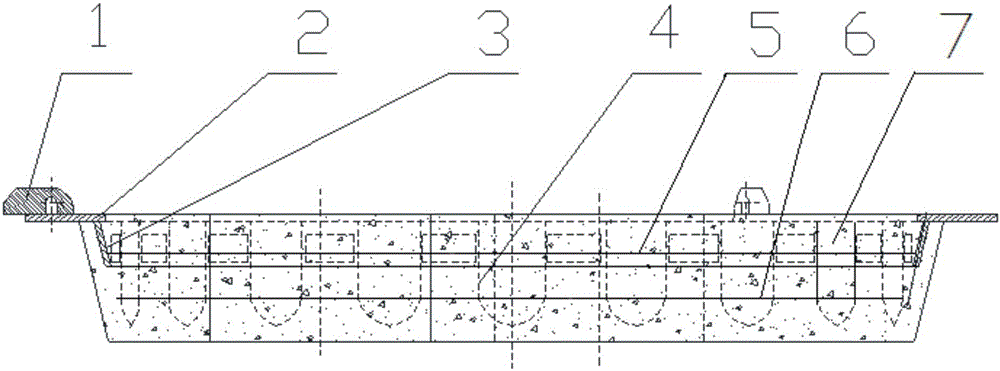

[0048] Such as image 3 , Figure 4 As shown, in this embodiment, an electric arc furnace cover includes a steel structure and a castable 7. The steel structure includes a circular load-bearing plate 2 and a skirt plate 3. The upper and lower sides of the circular load-bearing plate are provided with three hoists in the circumferential direction. Ear 1, a skirt plate is arranged on the lower side, the steel structure further includes a reinforcing member, the reinforcing member includes a U-shaped support rod 4 and a first connecting rib 5, the skirt plate is provided with a through hole, the first connecting rib It is inserted in the through hole and fixed. The inner side of the skirt board is provided with a U-shaped support rod and the first connecting rib is fixed. The cavity formed by the skirt board, the circular load-bearing plate, the U-shaped support rod and the first connecting rib is filled with castable and formed Overall, a graphite electrode hole 8 is provided in t...

Embodiment 2

[0050] The basic structure of an electric arc furnace cover of this embodiment is the same as that of Embodiment 1, with the difference that: in this embodiment, the U-shaped support rod 4 and the first connecting rib 5 are made of threaded steel.

Embodiment 3

[0052] The basic structure of an electric arc furnace cover of this embodiment is the same as that of embodiment 1, and the difference is that: in this embodiment, the steel structure further includes a second connecting rib 6, which is located in the first The connecting ribs 5 are arranged in parallel below, and the second connecting ribs are fixed to the U-shaped support rod 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com