Porous ceramsite and asphalt concrete and application thereof

A technology of asphalt concrete and porous ceramics, which is applied to the coagulation pavement, buildings, roads and other directions of on-site paving, can solve the problems of secondary pollution, etc., and achieve the effect of reducing the amount of consumption, good environmental protection benefits, and reducing the probability of occurrence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of porous ceramsite asphalt concrete with ultra-thin wearing layer of automobile exhaust gas degradation

[0040] 1. Containing nano-TiO 2 Porous ceramsite precast

[0041] (1) Nano-TiO 2 optimal dosage of

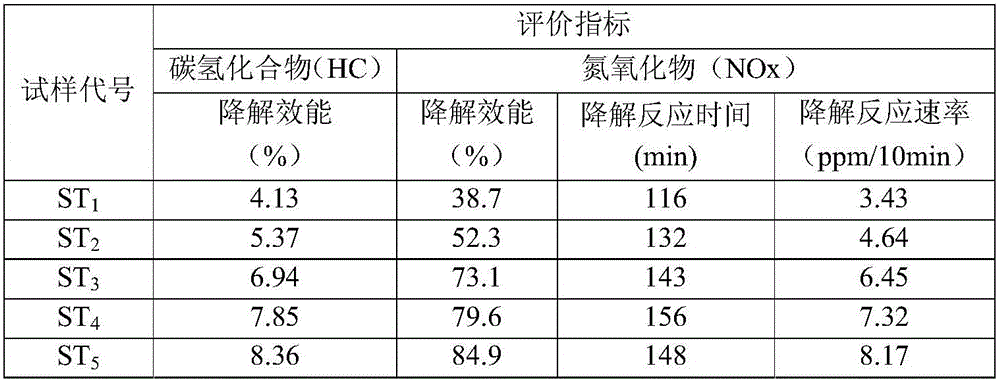

[0042] Nano TiO 2 Based on the mass percentage of the porous ceramsite, the five dosages of 3%, 4%, 5%, 6% and 8% were selected for nano-TiO 2 Orthogonal test of powder tail gas degradation efficiency. For the convenience of expression, the sample codes are given in Table 1.

[0043] Table 1 Nano TiO 2 Sample codes of different dosages

[0044] Sample code

ST 1

ST 2

ST 3

ST 4

ST 5

Nano-TiO 2 Dosage / %

3%

4%

5%

6%

8%

[0045] Table 2 Nano TiO 2 Tail gas degradation efficiency of different dosage samples

[0046]

[0047] Table 2 shows that: with nano-TiO 2 With the increase of the dosage, the exhaust gas degradation efficiency increases synchronously, but the incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com