Method for carbonizing forestry waste in red-soil hilly area and application of method in soil acidity improvement

A technology for forestry waste and hills, applied in the field of waste resource utilization and soil improvement, can solve the problems of low temperature, complicated application method, long pyrolysis time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Application of forestry waste biochar to improve acidic soil in red soil hilly area

[0030] The masson pine and fir residues collected in the red soil hilly area were naturally air-dried and crushed to a diameter of 1-5 cm, and heated to 480°C at a rate of 15-20°C / min in a conventional muffle furnace. Keep for 1.5 h; then, naturally cool to room temperature, which is the biochar product.

[0031] The obtained biochar was crushed to a diameter of <1 mm, mixed with the typical acidic soil Quaternary red clay (0-30 cm) in this area at a conversion ratio of 0.7 t / ha, and cultivated in the dark at 25°C. Add deionized water to each treatment regularly, keep the humidity at about 16%, and cultivate for 65 days;

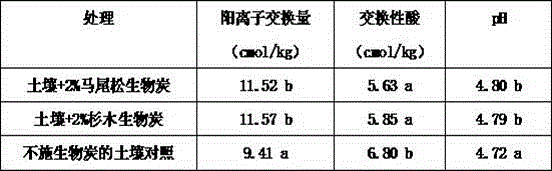

[0032] After the cultivation, the results are shown in Table 1. Compared with the soil control without biochar, the soil with masson pine and Chinese fir residual biochar was applied, and the pH, exchangeable acid, and cation exchange capacity that charac...

Embodiment 2

[0036] Example 2: Application of forestry waste biochar combined with nitrogen fertilizer in red soil hilly area to improve acidic soil

[0037] The masson pine and fir residues collected in the red soil hilly area were naturally air-dried and crushed to a diameter of 1-5 cm, and the temperature was raised to 450°C at a rate of 15-20°C / min in a conventional muffle furnace. Keep it for 1 hour; then, cool it down to room temperature naturally, which is the biochar product.

[0038] The two kinds of biochar were mixed with the typical acidic soil "Huangjin mud" (0-30 cm) in this area at a conversion ratio of 0.7 t / ha, and nitrogen fertilizer was applied (converted at an application rate of 350 kg / ha). They were cultured in the dark at 25°C, and deionized water was regularly added to each treatment during the culture process, the humidity was kept at about 16%, and the culture duration was 60 days. After the cultivation, the results are shown in Table 2 below. Compared with the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com