Intelligent warehousing system based on mobile robots

A mobile robot and intelligent warehousing technology, applied in the field of warehousing, can solve the problems of low efficiency of manual picking and shipping, imperfect data management, and insufficient space utilization, so as to improve the efficiency of picking operations, facilitate sorting, and automate high level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

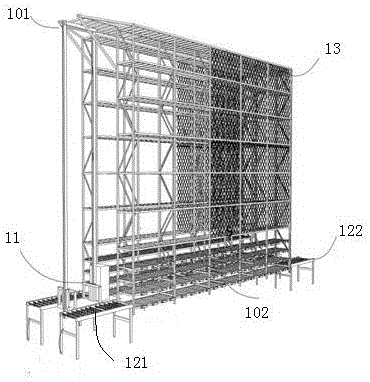

[0051] This embodiment proposes an intelligent storage system based on mobile robots, such as figure 1 shown, including:

[0052] The three-dimensional shelf 10 is divided into a plurality of warehouse locations by several horizontal horizontal beams, horizontal partitions and several vertical vertical columns vertically intersecting, and the multiple warehouse locations are divided into vertically The high-level bulk storage area 101 and the low-level dismantling zero area 102, the high-level bulk storage area 101 is used to store palletized goods, and the low-level dismantled zero area 102 is used to store dismantled goods, and there is a sorting area stop correspondingly in front of each row of warehouse positions; The intelligent storage system based on the mobile robot of the embodiment is especially aimed at the daily necessities storage system of e-commerce zero pick-up. Since e-commerce companies such as Taobao and JD.com generally sell online, users place orders onlin...

Embodiment 2

[0070] Based on the intelligent storage system in the first embodiment, this embodiment proposes an intelligent storage method based on mobile robots, wherein the intelligent storage method in this embodiment includes the intelligent storage system involved in the first embodiment, and the accompanying drawings are also see Figure 1-Figure 6 shown, including the following steps:

[0071] The steps of goods warehousing and shelving include:

[0072] S11. The intelligent warehouse management system sends the storage task to the intelligent warehouse control system;

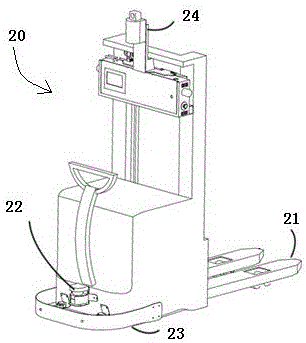

[0073] S12. The intelligent warehousing control system sends a warehousing instruction and a driving route to the unmanned forklift mobile robot, and the unmanned forklift mobile robot intelligently navigates to the storage pallet, and forks the goods to the roller line;

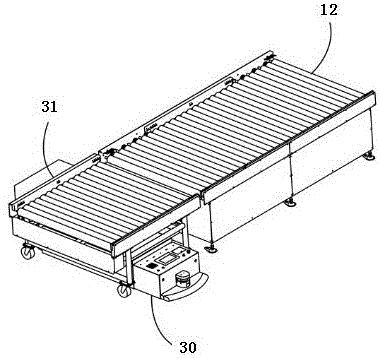

[0074] S13. The roller line is connected to the instruction sent by the intelligent storage control system to push the goods forward, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com