Loading dumper

A technology for unloading trucks and frames, which is applied in the direction of trolleys, motor vehicles, multi-axis trolleys, etc. It can solve the problems of small equipment structure damage, low work efficiency, and failure to function normally, and achieve the effect of avoiding falling off and facilitating assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

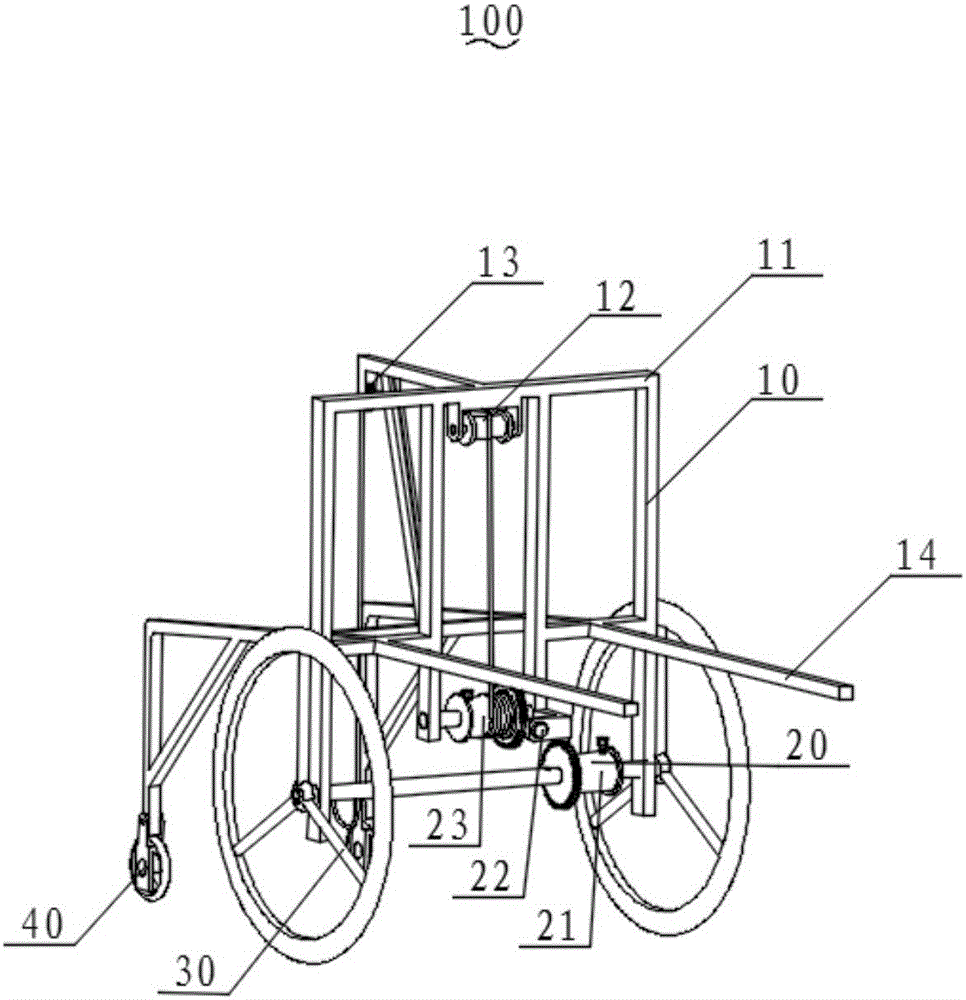

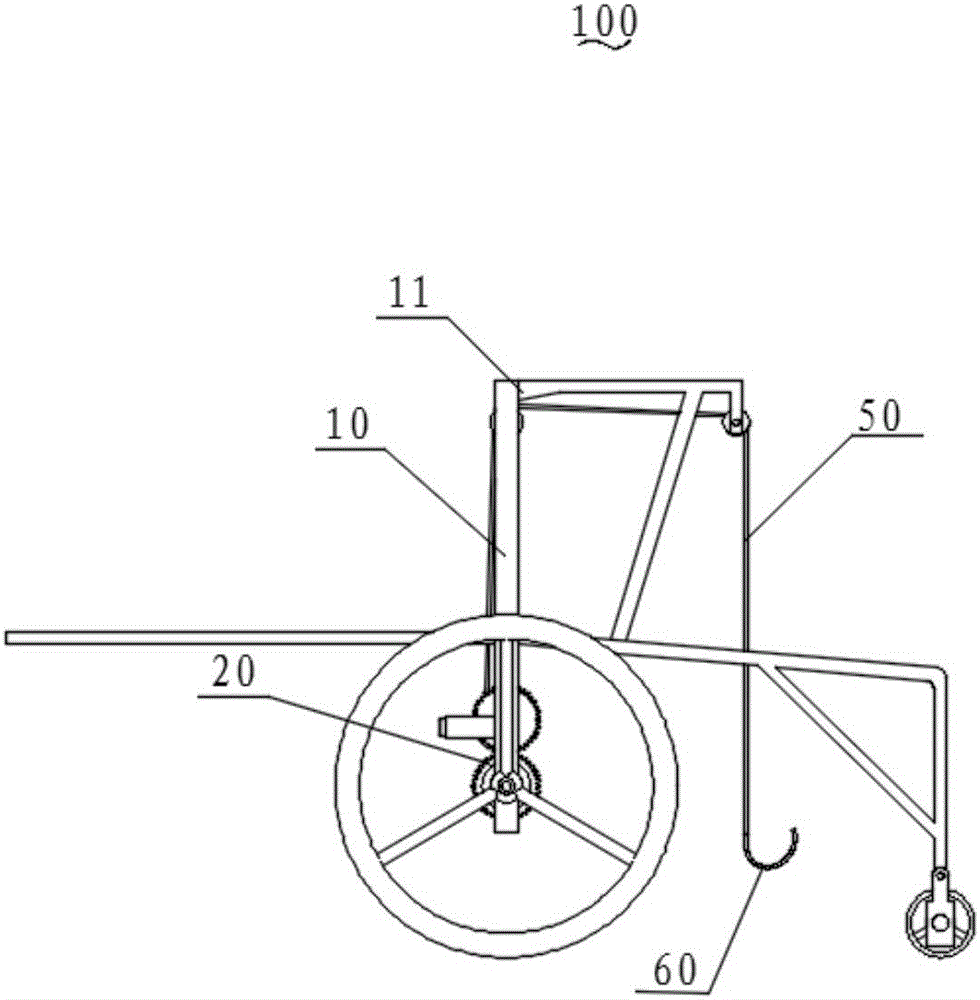

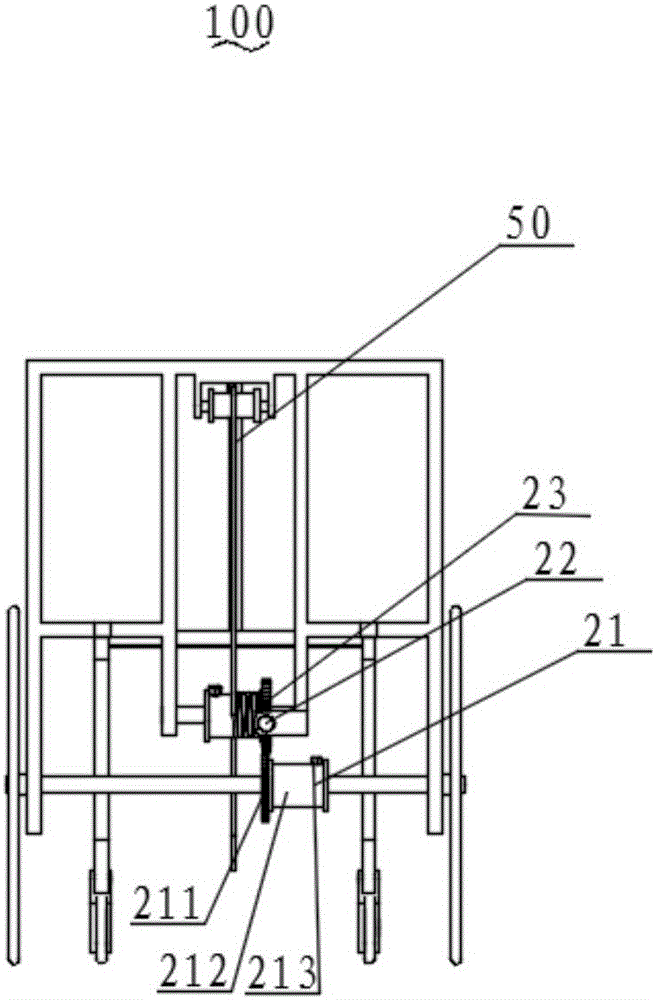

[0031] Please refer to Figure 1 to Figure 7 , a loading and unloading truck, including a frame 10, and also includes a hook 60, a coil 50 and a gear set 20, the gear set 20 is arranged on the frame 10, and the hook 60 and the gear set 20 are connected through the coil 50. The gear set 20 includes an upper gear 23 , a lower gear 21 and a check rod 22 , and one end of the coil 50 is wound on the upper gear 23 . The lower gear 21 meshes with or separates from the upper gear 23 , and when the lower gear 21 meshes with the upper gear 23 , it drives the upper gear 23 to rotate to draw the coil 50 . The non-return tappet 22 is provided with a telescopic connecting rod 223 matched with the tooth groove of the upper gear 23 , and one end of the connecting rod 223 is provided with a blocking surface 228 and a sliding surface 229 . When the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com