Decorative film and preparation method thereof

A decorative film and decorative layer technology, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problem that the decorative film cannot be repaired, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

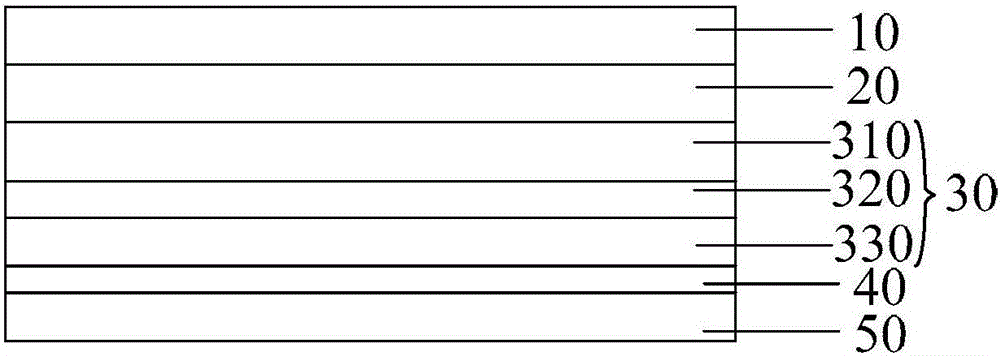

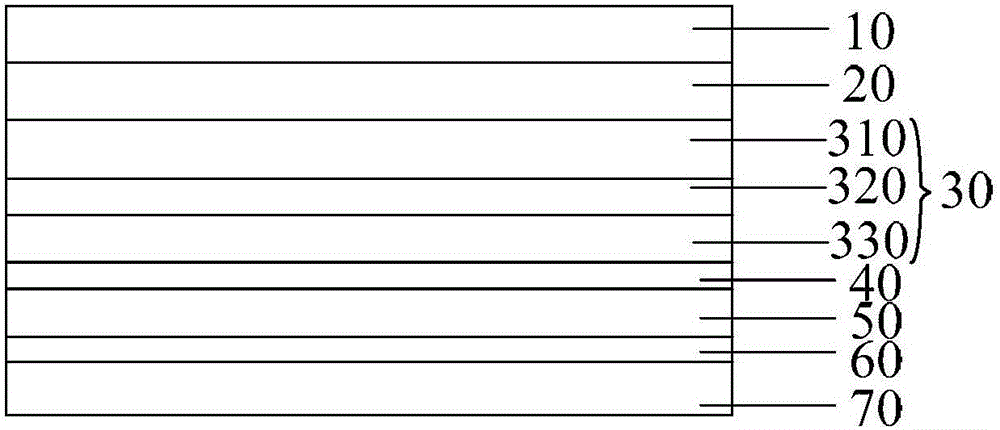

[0046] According to another aspect of the present application, a method for preparing a decorative film is provided. The preparation method includes the following steps: disposing a raw material including a self-repairing polymer material on a base material layer to form a self-repair layer; A decoration layer is provided on the surface away from the self-healing layer 10; a first adhesive layer and a PVC substrate are arranged in sequence on the side of the decoration layer away from the base layer.

[0047] In the above power generation method, since the self-healing polymer material is used to form a self-healing layer, and the self-healing polymer material can sense changes in external environmental factors and make appropriate responses to restore its own performance, the self-healing layer with the above-mentioned The decorative film can have the function of self-healing, thereby reducing the damage of the decorative layer due to heat, mechanical and chemical factors; and...

Embodiment 1

[0064] The decorative film provided in this embodiment includes a decorative layer, a first adhesive layer, a PVC substrate and a self-repairing layer, and the preparation method includes the following steps:

[0065] First, 50 parts by weight of the first transparent polymer solution with photocurable resin PAG001 (provided by Kangdexin) is coated on a PET substrate with a thickness of 50 μm by a rubber wheel with a concave-convex pattern structure, and placed at 500 mJ / cm 2 In the UV transport machine, dry to obtain a transparent cured layer with a three-dimensional pattern structure; the acrylic coating solution MAG001 (provided by Kangdexin) is diluted with ethyl acetate to be the second transparent polymer solution of 50 parts by weight with a solid content of 20%. Add the color paste OAG001 (provided by Bayer) of 0.2 parts by weight of local gold color as an inorganic pigment and disperse it evenly, apply the coloring paint to the decorative pattern surface of the transpa...

Embodiment 2

[0069] The decorative film provided in this embodiment includes a decorative layer, a first adhesive layer, a PVC substrate and a self-repairing layer, and the preparation method includes the following steps:

[0070] First, 50 parts by weight of the first transparent polymer solution with photocurable resin PAG001 (provided by Kangdexin) is coated on a PET substrate with a thickness of 50 μm by a rubber wheel with a concave-convex pattern structure, and placed at 500 mJ / cm 2 In the UV transport machine, dry to obtain a transparent cured layer with a three-dimensional pattern structure; the acrylic coating solution MAG001 (provided by Kangdexin) is diluted with ethyl acetate to be the second transparent polymer solution of 50 parts by weight with a solid content of 20%. Add the color paste OAG001 (provided by Bayer) of 0.5 parts by weight of local gold color as an inorganic pigment and disperse it evenly, apply the coloring paint to the decorative pattern surface of the transpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com