Lever type clamping jig

A lever-type, clamping technology, used in manufacturing tools, workpiece clamping devices, etc., can solve the problems of clamping plate rotation, safety accidents, etc., and achieve the effect of convenient locking or unlocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

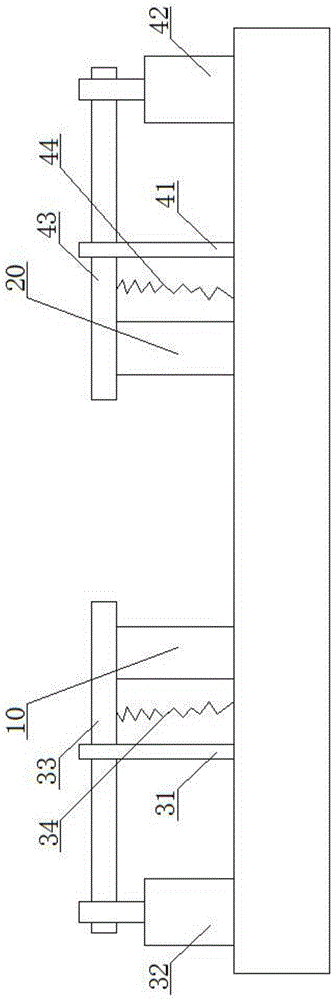

[0017] see figure 1 , as shown in the legend therein, a lever type clamping jig includes a first support block 10, a second support block 20, a first clamping assembly and a second clamping assembly, the first support block 10 and the second The support block 20 is arranged left and right, and the above-mentioned first clamping assembly includes a first support 31, a first driving device 32 and a first clamping plate 33, and the first support 21 and the first driving device 32 are sequentially arranged on the first support block. 10, the first clamping plate 33 is rotatably set with the first support 31 as a fulcrum, the left end of the first clamping plate 33 is hingedly connected with the driving end of the first driving device 32, and the first clamping plate 33 Rotate the right end of the first support block 10 to the upper set position or rotate to the left set position of the first support block 10, the second clamping assembly includes the second support 41, the second ...

Embodiment 2

[0027] The rest are the same as in Embodiment 1, except that the bottom of the right end of the horizontal plate of the above-mentioned first clamping plate is provided with several first grooves uniformly distributed, and the bottom of the left end of the horizontal plate of the above-mentioned second clamping plate is provided with There are several second grooves evenly distributed, and the grooves of the first groove and the second groove are triangular grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com