Chamfering machine

A chamfering machine and chamfering technology, applied in the field of chamfering machines, can solve the problems of long time-consuming, batch processing of unfavorable materials, and low chamfering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

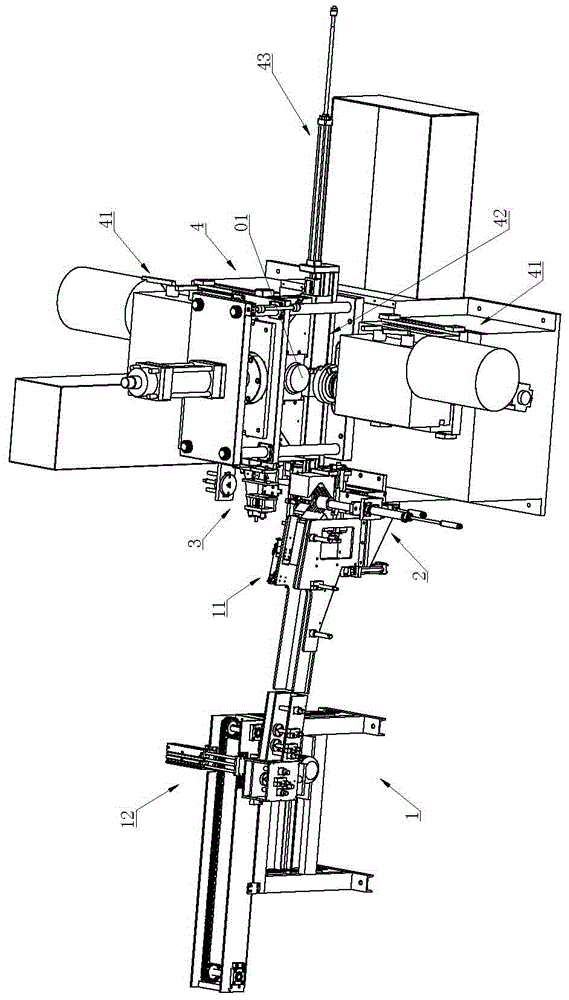

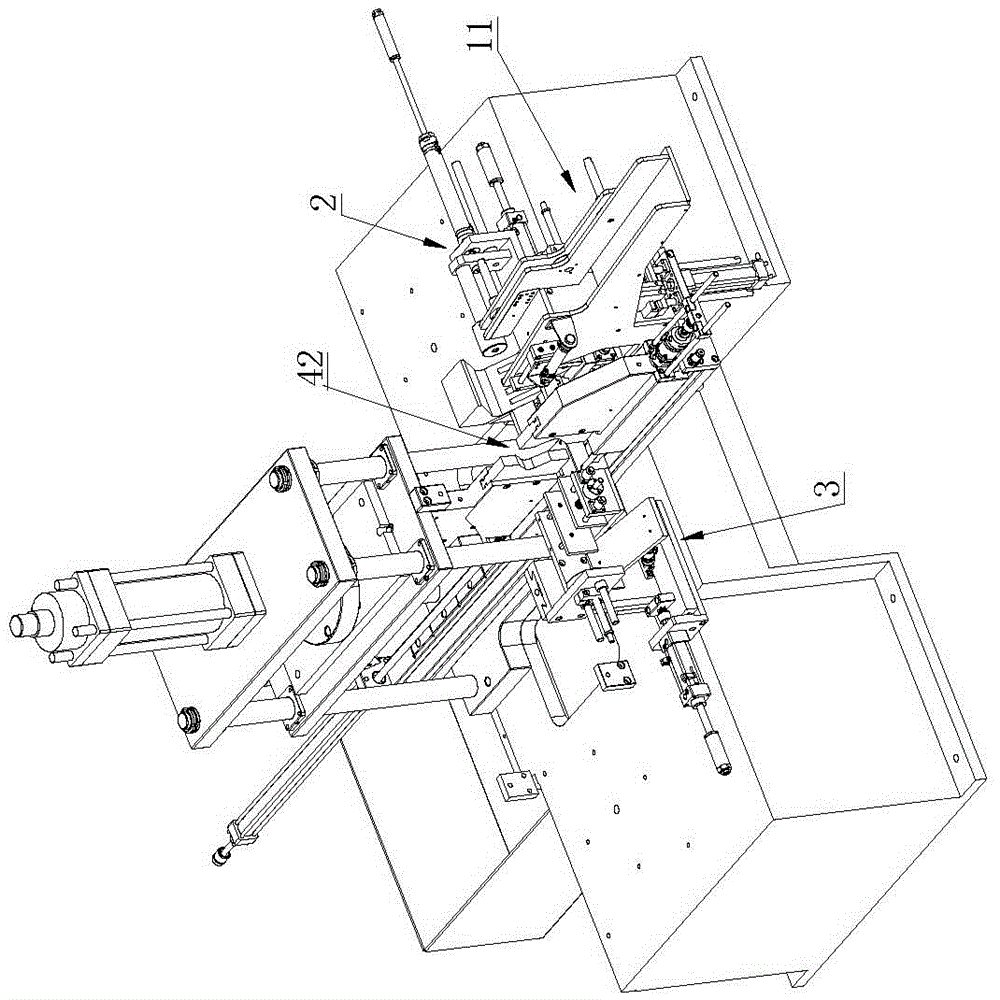

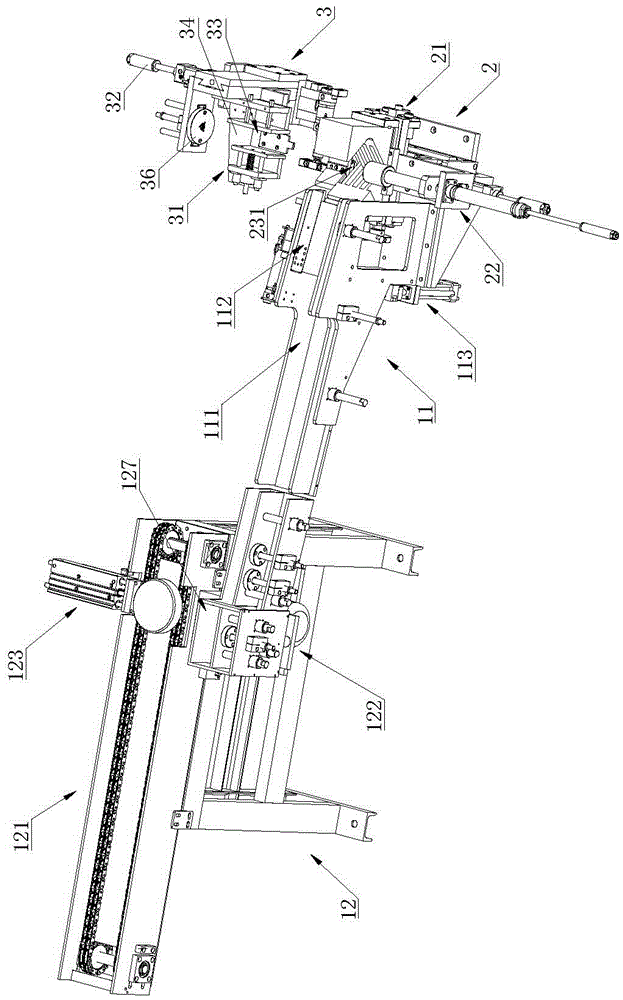

[0028] Such as Figure 1 to Figure 10 Shown, a kind of chamfering machine comprises feeding device 1, is arranged on the push-out device 2 of feeding device 1 outlet, is arranged on the unloading device 3 of push-out device 2 side and is used for carrying out chamfering to material Chamfering device 4; Described chamfering device 4 is provided with chamfering mechanism 41, is used for clamping mechanism 42 of clamping material and is used to drive the fixture moving driving mechanism 43 of clamping mechanism 42 to move, when clamping mechanism 42 takes material or unloads During the material, the clamp mechanism 42 is located between the pushing device 2 and the unloading device 3 . Specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com