Vehicle water pump shell inner hole machining device

A processing device and pump casing technology, which is applied in the field of mechanical processing tooling, can solve the problems of pump casings that cannot be clamped, achieve the effects of reducing loading and unloading time, reducing the difficulty of clamping, and improving enterprise benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

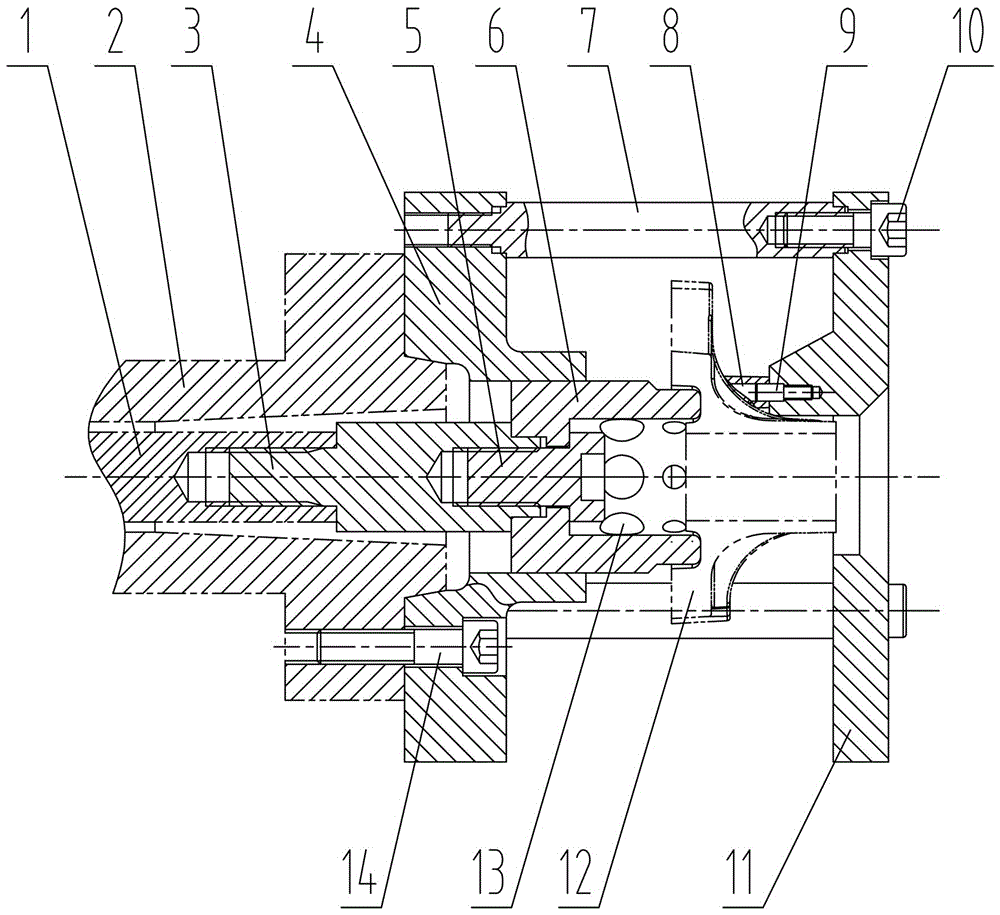

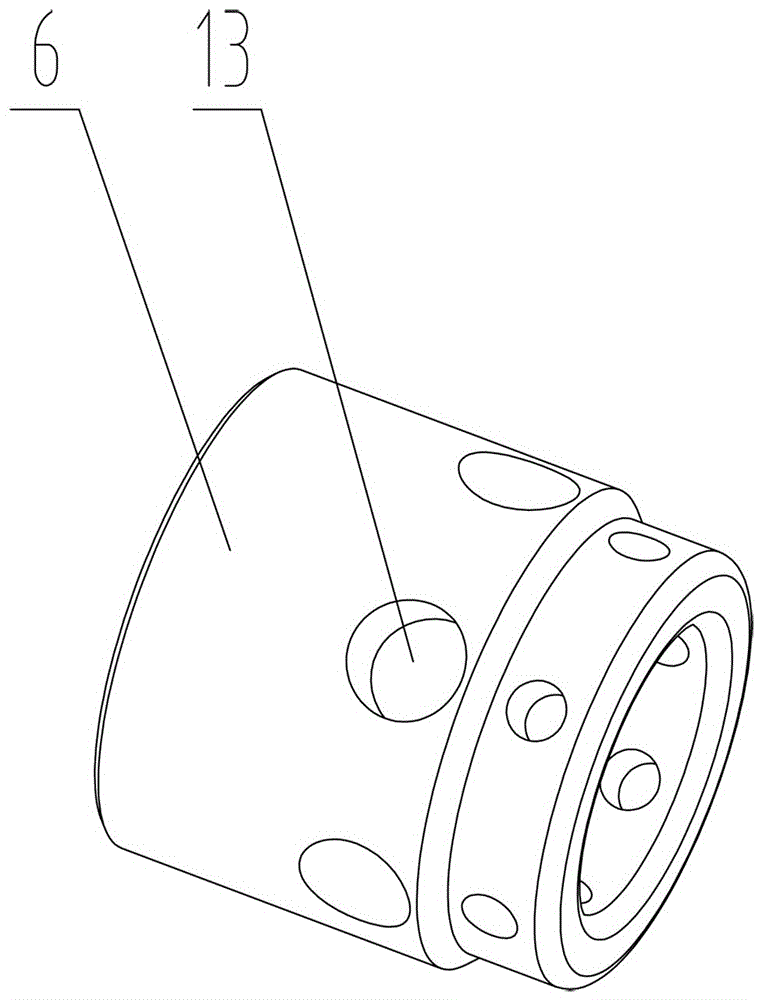

[0017] Figure 1 ~ Figure 2 One end of the tie rod adapter sleeve 3 in the shown automobile water pump casing inner hole processing device of the present invention is locked on the pull rod 1 of the lathe through threads; the clamp body 4 is fixed on the lathe main shaft 2 through long screws 14; The top tight sleeve 6 is installed on the pull rod adapter sleeve 3 through the large screw 5, and the outer circle of one end is sleeved in the clamp body 4 in the manner of axial hole clearance fit, and a plurality of drainage holes 13 are drilled on the outer circle of the other end, and are connected with the outer circle of the other end. The inner holes communicate with each other; the shaft at one end of the support column 7 cooperates with the hole on the clamp body 4 and locks, and the shaft at the other end cooperates with the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com