A processing device for non-uniform passivation hard rotary milling tool

A processing device and non-uniform technology, which is applied in the direction of milling cutters, manufacturing tools, metal processing equipment, etc., can solve the problem of easy local damage of the cutting edge, achieve the effects of reducing processing costs, improving processing quality, and preventing early damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

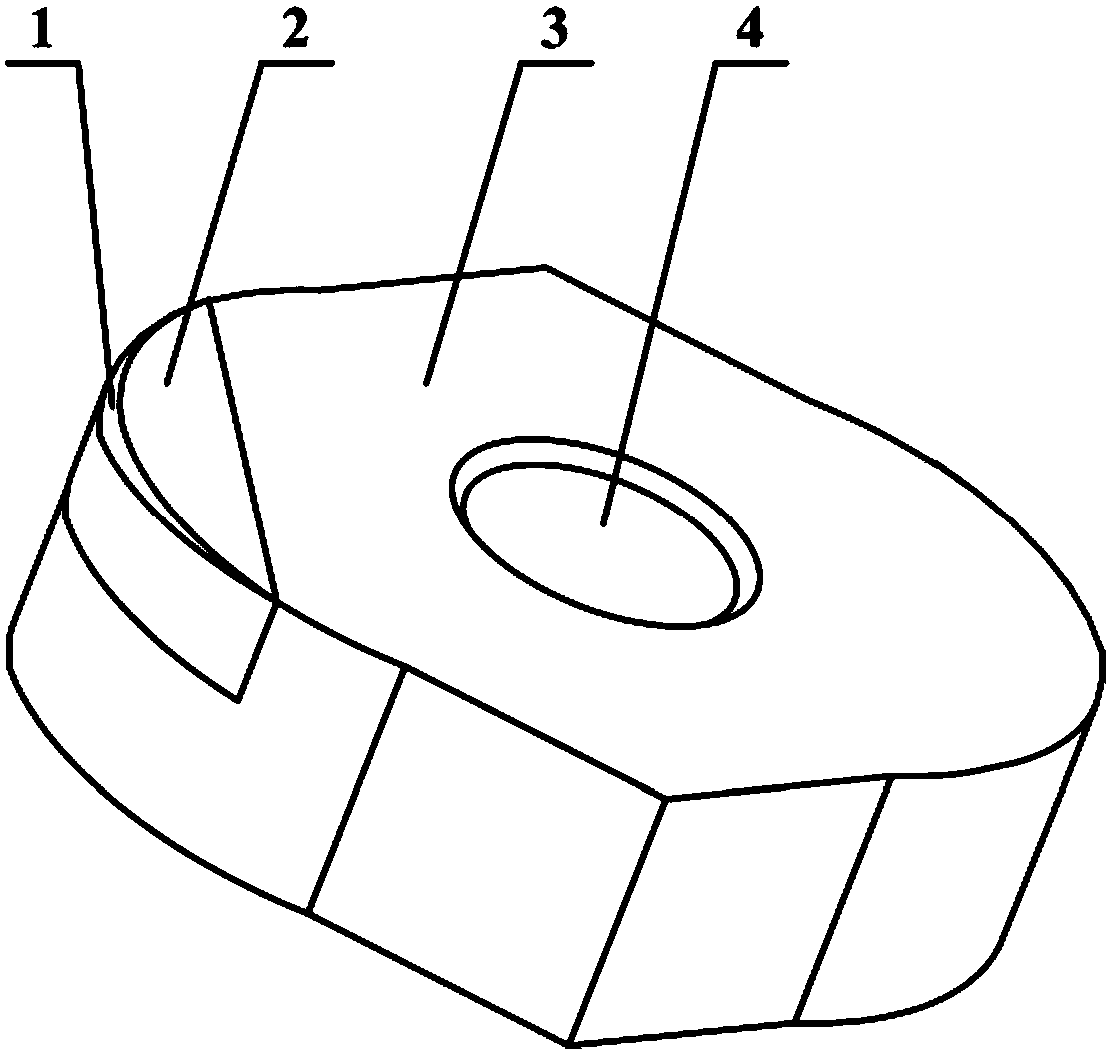

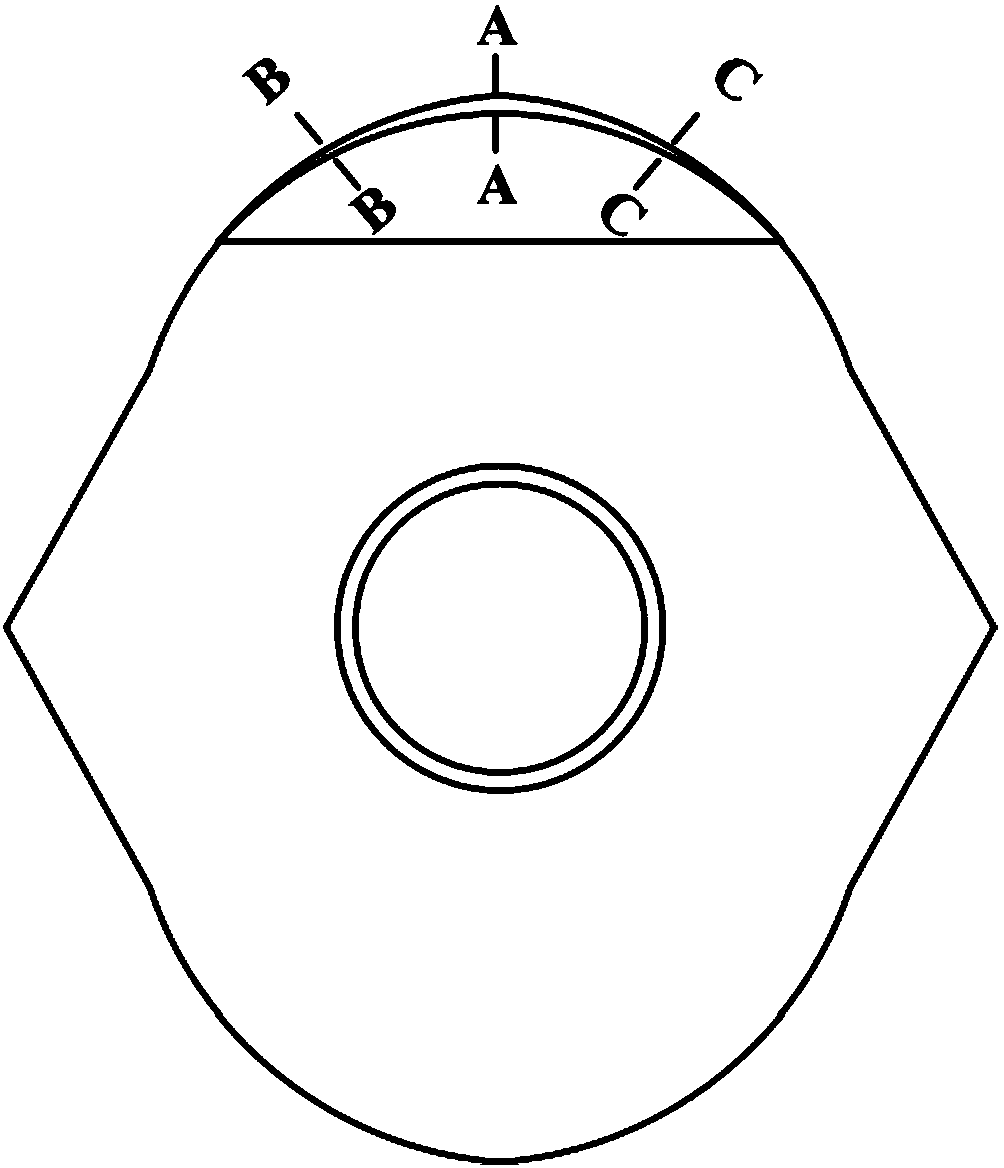

[0029] Such as Figure 1-2 shown. A cutting edge non-uniform passivation hard rotary milling tool of the present invention comprises a PCBN cutter body 2, a cemented carbide substrate 3, a tool mounting hole 4 and a non-uniform passivation cutting edge 1;

[0030] The PCBN cutter body 2 is in the shape of double-arc splicing, brazed to one end of the cemented carbide substrate 3; a circular cutter mounting hole 4 is opened in the middle of the cemented carbide substrate 3;

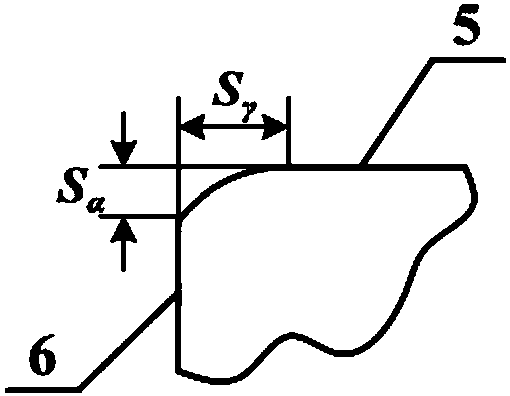

[0031] The non-uniform passivation cutting edge 1 is located at the end of the PCBN cutter body 2, the cutting edge radius is the largest at the middle position, gradually decreases towards both ends, and is symmetrical with respect to the middle position; the middle part of the cutting edge adopts a waterfall-shaped cutting edge (front knife The passivation length of face 5 is greater than the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com