A boring bar device for deep hole machining

A boring bar and deep hole technology, which is applied to boring bars, metal processing equipment, manufacturing tools, etc., can solve the problems of restricting the processing quality and processing efficiency of deep holes, the spindle cannot be directly processed, and the processing accuracy is reduced, etc., and achieves a simple structure. , Reduce the natural flexibility, improve the effect of supporting rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

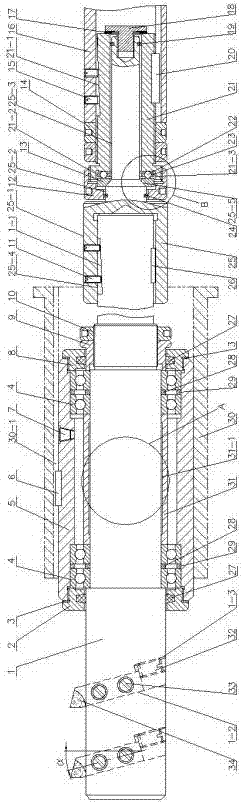

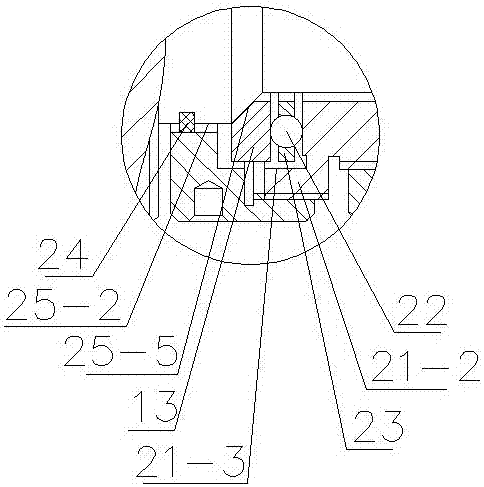

[0025] In Example 1, see Figure 1 ~ Figure 3 , a boring bar device for deep hole machining, installed on a boring machine, including a boring bar floating chuck device, the boring bar floating chuck device includes a socket shaft 25, a threaded cover 12, and a tube coaxial with the socket shaft 25 Shaped tail handle 21, coaxially sleeved on the connecting sleeve 16 on the outer peripheral surface of the tail handle 21, and the connecting sleeve 16 is coaxially installed on the boring machine main shaft.

[0026] Sleeve shaft 25 comprises shaft diameter successively decreasing and coaxial shaft section one 25-1, shaft section two 25-2, shaft section three 25-3, and one end of shaft section one 25-1 is provided with coaxial sleeve Hole 25-4, the head of the boring bar 1 is coaxially fitted in the sleeve hole 25-4, the boring bar 1 and the sleeve shaft 25 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com