Bending device for heating pipe of evaporator

A technology of bending device and heating tube, which is applied in the direction of heat exchange equipment, etc., can solve the problems of low work efficiency and inability to take out the workpiece, and achieve the effect of rapid operation, simple structure and improved bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

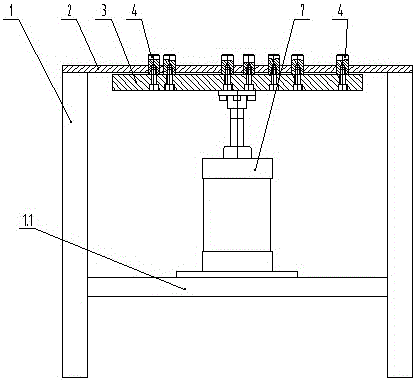

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

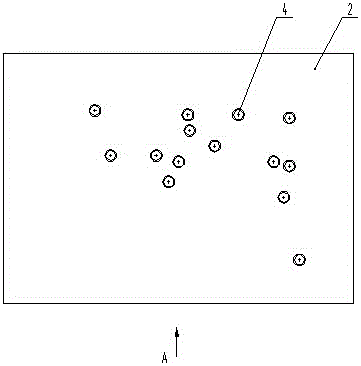

[0016] The heating tube bending device of the evaporator shown in the accompanying drawings includes a working table 1, an upper template 2, a lower template 3, a pipe bending wheel 4, and a power cylinder 7; , the upper part is fixedly connected with the flat upper formwork 2; the lower formwork 2 is provided with the lower formwork 3, and the upper end surface of the lower formwork 3 is fixedly connected with several vertical and columnar bending wheels 4; the upper formwork 2 is provided with the bending wheels 4 The upper and lower through holes corresponding to the positions allow the pipe bending wheel 4 to pass through, and the gap between the pipe bending wheel 4 and the through hole 2.1 of the upper template 2 is matched; the power cylinder 7 is vertically arranged on the lower end surface of the lower template 3 and the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com