Weighing, scanning and body measuring trinity machine

A three-in-one, weighing technology, applied in the detailed information of weighing equipment, weighing, measuring devices, etc., can solve the problems of reducing labor costs, reducing manpower and material resources, and high labor costs, achieving stable dynamic weighing and uniform force. , the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

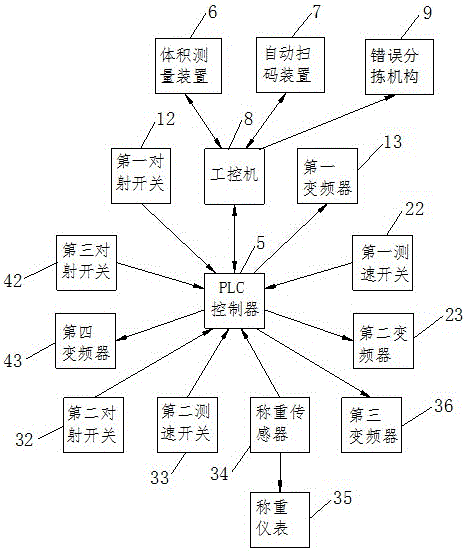

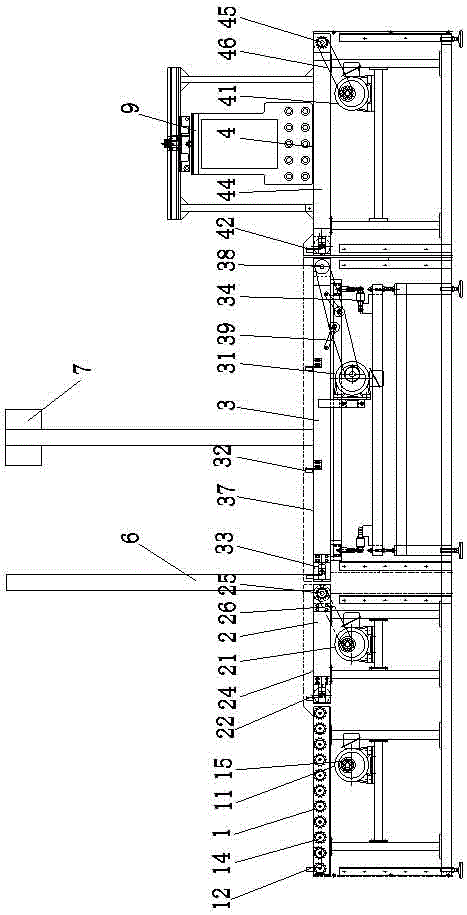

[0019] Such as figure 1 As shown, a three-in-one weighing, scanning, and body measuring machine includes a loading drum line 1, an incoming belt line 2, a weighing belt line 3, a shipping belt line 4, a PLC controller 5, a volume measuring device 6, and an automatic code scanning device. Device 7, industrial computer 8 and error sorting mechanism 9; according to the sequence of parcel passing, the loading drum line 1, incoming belt line 2, weighing belt line 3 and outgoing belt line 4 are fixed on the same base through the frame Above, the volume measuring device 6 is fixed at the gap between the incoming goods belt line 2 and the weighing belt line 3, and the automatic code scanning device 7 is fixed directly above the weighing belt line 3 through the first bracket, so The above error sorting mechanism 9 is fixed on the ground and is installed directly above the outgoing belt line 4; figure 2 As shown, the PLC controller 5 communicates bidirectionally with the industrial co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com