Mixing device based on improvement of moving convenience

A technology of mixing equipment and convenience, applied in the field of petroleum machinery auxiliary tools, can solve the problems of inconvenient movement and bottom damage, and achieve the effects of improving convenience, avoiding deformation and damage, and facilitating disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

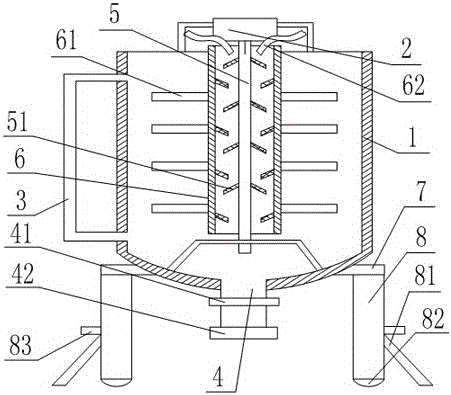

[0030] Such as figure 1 As shown, the mixing equipment based on improving the convenience of movement includes two fixed columns 8, on which a fixed plate 7 is arranged, and the middle part of the fixed plate 7 is provided with a circular through hole, and the tank body 1 passes through the circular through hole Fixed on the fixed plate 7, the bottom of the tank body 1 is provided with a discharge pipe 4, the discharge pipe 4 is provided with a valve 41, the top of the tank body 1 is provided with a motor 2, and the power output end of the motor 2 is connected with a rotating shaft 5, The rotating shaft 5 is arranged inside the tank body 1, and the rotating shaft 5 is connected to the cylinder body 6 through a connecting rod. An annular space is formed between the rotating shaft 5 and the cylinder body 6, and a feeding port 62 is arranged in the annular space, and a stirring device is provided on the outer wall of the cylinder body 6. The blades 61, the inner wall of the barre...

Embodiment 2

[0032] Such as figure 1 As shown, this embodiment is based on Embodiment 1, the side wall of the tank body 1 is provided with a bypass pipe 3, and the two ends of the bypass pipe 3 communicate with the upper end and the lower end of the tank body 1 respectively, and the bypass pipe 3 Made of transparent material; the outlet end of the discharge pipe 4 is provided with a joint 42; the side wall of the fixed column 8 is provided with a limit plate 83 that cooperates with the support plate 81; the inclined plate on the cylinder 6 51 is opposite to the direction of inclination of the swash plate 51 on the rotating shaft 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com