Scale inhibiting-dispersing agent for reverse osmosis membrane and preparation method thereof

A technology of scale inhibitor dispersant and reverse osmosis membrane, applied in semipermeable membrane separation, chemical instruments and methods, permeation/dialysis water/sewage treatment, etc., can solve the problems of reducing dosage, membrane pollution, etc. The effect of increasing the volume and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 2-methylene succinic acid-acrylic acid copolymer, polyepoxysuccinic acid, polyethylene glycol monoallyl ether, and 2,4-diaminotoluene into the reaction equipment in sequence, and stir at 35°C for 1 hour , and then evacuated at 40°C for 1.5 hours, stirred evenly and then left to stand, then the scale inhibitor dispersant for reverse osmosis system was obtained. The weight percentage of each raw material is: 2-methylene succinic acid-acrylic acid copolymer 28%, polyepoxysuccinic acid 37%, polyethylene glycol monoallyl ether 27%, 2,4-diamino Toluene 8%.

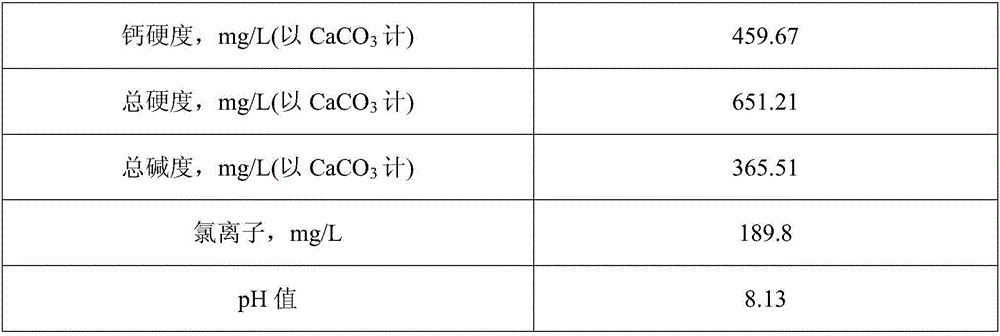

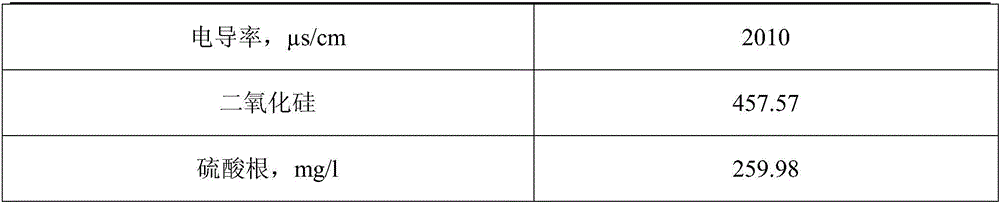

[0024] The antiscaling and dispersing agent prepared in Example 1 was used in a 120-ton one-stage two-stage reverse osmosis system of a certain power plant, and the water quality analysis is shown in Table 1:

[0025] Table 1 Water quality analysis results of a 120-ton one-stage two-stage reverse osmosis system in a power plant

[0026] Calcium hardness, mg / L (as CaCO 3 count)

[0027] Dilute the 8-fold ...

Embodiment 2

[0029] Add 2-methylene succinic acid-acrylic acid copolymer, polyepoxysuccinic acid, polyethylene glycol monoallyl ether, and 2,4-diaminotoluene into the reaction equipment in sequence, and stir at 45°C for 1 hour , and then evacuated at 45°C for 1 hour, stirred evenly and then left to stand, then the scale inhibitor dispersant for reverse osmosis system was obtained. The weight percentage of each raw material is: 38% of 2-methylene succinic acid-acrylic acid copolymer, 32% of polyepoxysuccinic acid, 20% of polyethylene glycol monoallyl ether, 2,4-diamino Toluene 10%.

[0030] The scale inhibitor dispersant prepared in Example 2 was used in an 80*2 ton first-stage two-stage reverse osmosis system in a steel plant, and the water quality analysis is shown in Table 2:

[0031] Table 2 Water quality analysis results of a 120-ton one-stage two-stage reverse osmosis system in a power plant

[0032]

[0033]

[0034] Dilute the 8-fold concentrated solution of the scale inhibi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com