Demister blade unit for demister, efficient demister and application

A technology of mist eliminator and blade, which is applied in the field of high-efficiency mist eliminator and application, mist eliminator blades for mist eliminator, and achieves the effect of reducing scour, improving mist eliminator efficiency and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings and through the examples. The following examples are only illustrative, not restrictive, and the protection scope of the present invention cannot be limited by the following description.

[0024] Structures, connection relationships, etc. that are not described in detail in the present invention can be understood as conventional technical means in the field.

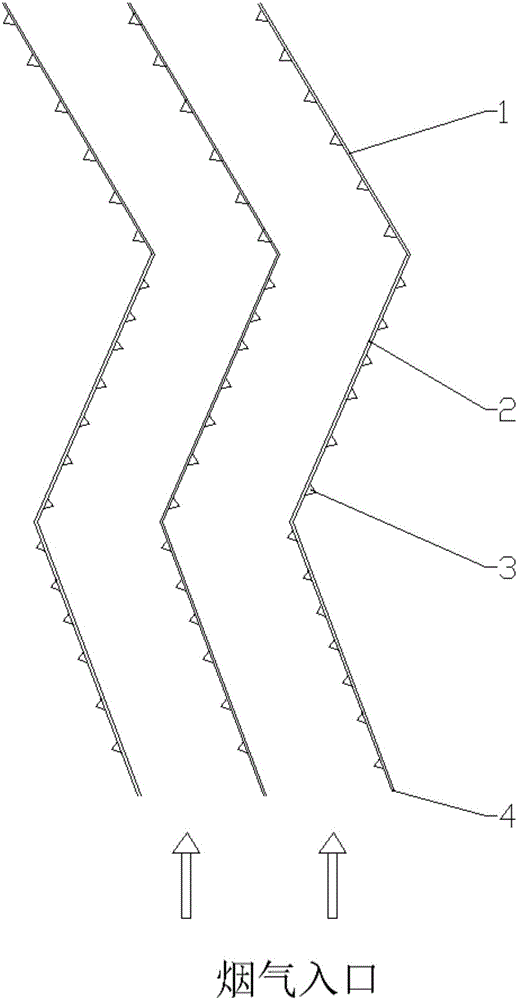

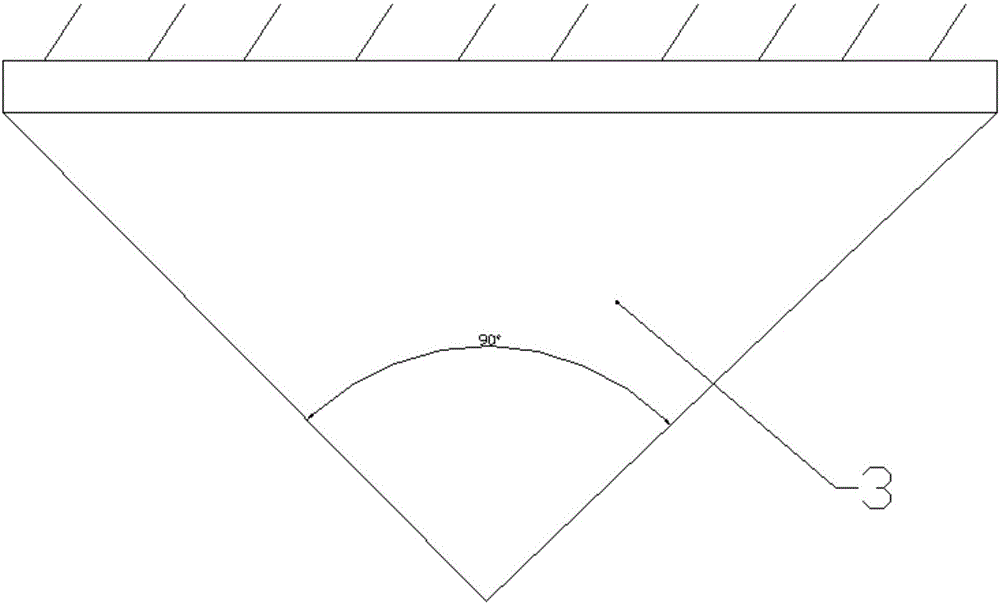

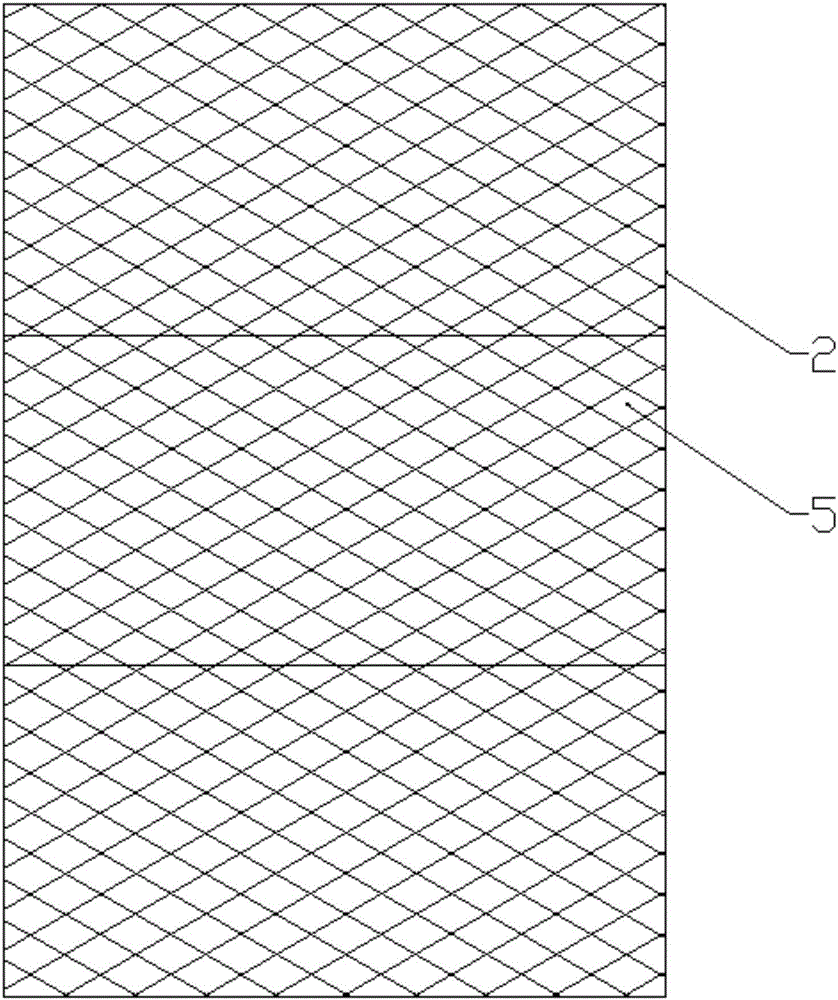

[0025] A demister blade for a demister, such as figure 1 , figure 2 and image 3 As shown, the mist eliminator blade includes a plurality of blades 4 arranged in parallel and spaced apart, for example, the spacing of each blade is 5-60mm, the blade height is 100-350mm, and each blade includes a blade body 1, a mesh structure layer 2 and a cone 3, the material of the cone is stainless steel and the surface energy range is (1-3) N / m, and the cone is spaced (for example, welded) along the blade body on the outside ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Surface energy | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com