Portable sleeping mat and production method thereof

A production method and portable technology, which can be applied to stuffed mattresses, mattresses, spring mattresses, etc., can solve the problems of high production cost, time-consuming and laborious, etc., and achieve the effects of convenient transportation and logistics, reduction of production costs, and good ventilation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention are described in conjunction with the accompanying drawings.

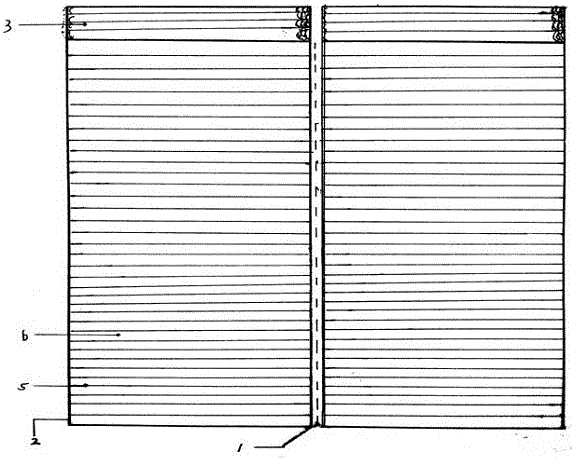

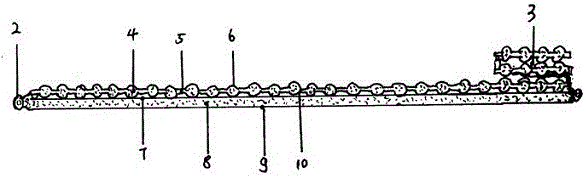

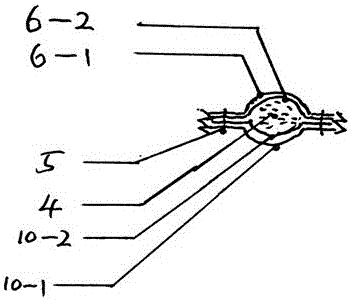

[0019] A portable sleeping pad and a production method thereof, including a sleeping pad core and a pillow forming 4 , a sleeping pad forming 2 and a sleeping pad combination 1 . Wherein the sleeping pad combination 1 is to sew zippers, laces, buttons and similar connection tools in the middle of the gap between two sleeping pads to connect them together to form a portable sleeping pad that meets the specification requirements. Sleeping pad forming 2 is to sew the core of the sleeping pad and the composite fabric together through the edge-surrounding technology with side bands to form a sleeping pad. Sleeping pad core and pillow forming 4 is to use a portable sleeping pad core automatic filling machine to fill buckwheat husks into several rows of cloth bag rows 6 and 10, and after sealing with a sealing device, the sleeping pad core and pillow are formed. pillow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com