Transverse folding mechanism for empennage

A technology of horizontal folding and empennage, which is applied in the direction of fuselage, aircraft parts, transportation and packaging, etc. It can solve the problems of small torque and unsatisfactory, and achieve the effect of stable state, simple structure and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

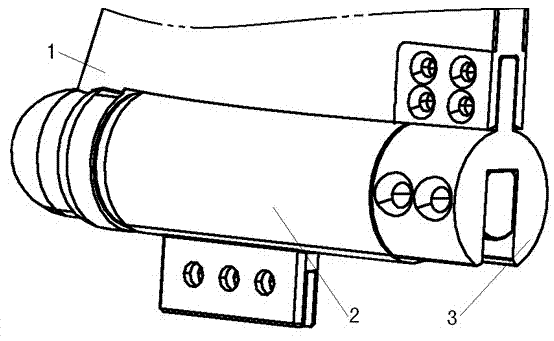

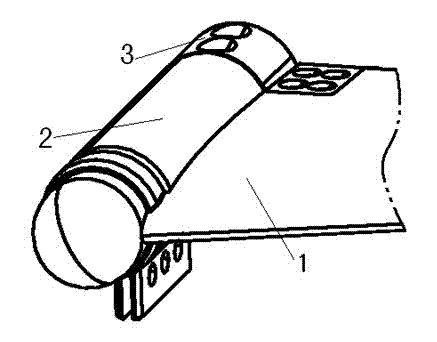

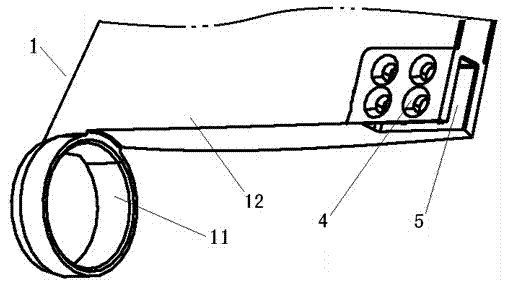

[0021] attached by Figure 1-3 The lateral folding mechanism of the empennage is composed of the empennage joint 1, the rotating actuator 2, the plug seat 3, etc. When the empennage is in the initial position, the rotating actuator 2 is provided with a shear pin, which is a locking and unlocking device for the entire mechanism, ensuring The empennage is in a fixed state, and the rotating actuating body 2 is provided with a pyrotechnic rotating actuating device, which is the power source 6 of the whole mechanism, and provides rotational torque for the empennage to be deployed in place. Its working process is as follows: after the task machine gives instructions, the rotating actuator 2 starts to work to generate a rotating torque. When the provided torque is greater than the external force that the shearing pin can bear, the shearing pin is sheared, the mechanism is unlocked, and then the rotary joint 24 Start to rotate, and then drive the plug seat 3 to rotate, and drive the e...

Embodiment 2

[0023] attached by Figure 1-3 The lateral folding mechanism of the empennage is composed of the empennage joint 1, the rotating actuator 2, the plug seat 3, etc. When the empennage is in the initial position, the rotating actuator 2 is equipped with a pin puller connected to the control of the task machine, which is the whole mechanism locked. And the unlocking device ensures that the empennage is in a fixed state, and a hydraulic pump is installed in the rotating actuating body 2, which is the power source 6 of the whole set of mechanisms and provides rotational torque for the empennage to be deployed in place. The working process is as follows: after the mission machine gives instructions, the pin puller works first, the pin puller is pulled out, the rotating actuator 2 is unlocked, and then the hydraulic pump starts to work to generate a torque, and the rotary joint 24 starts to rotate, thereby driving the plug socket 3 Rotate, drive the empennage joint 1 to rotate throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com