Tactile sensor based on friction power generators and robot tactile perception system

A friction generator and tactile sensor technology, applied in the sensor field, can solve the problems of complex structure, low precision and low sensitivity of the sensor, and achieve the effect of high sensitivity and precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

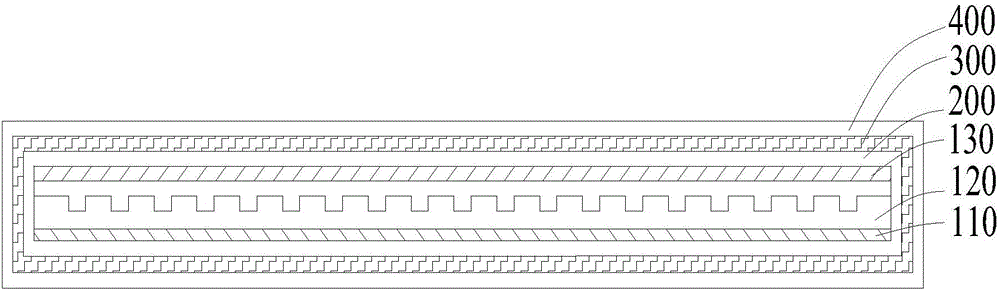

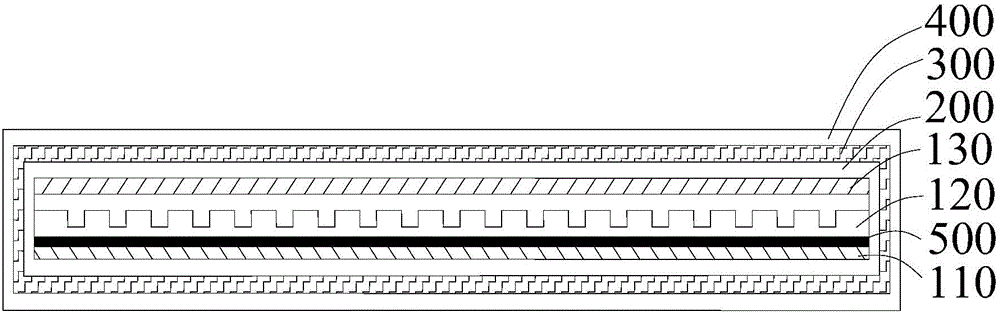

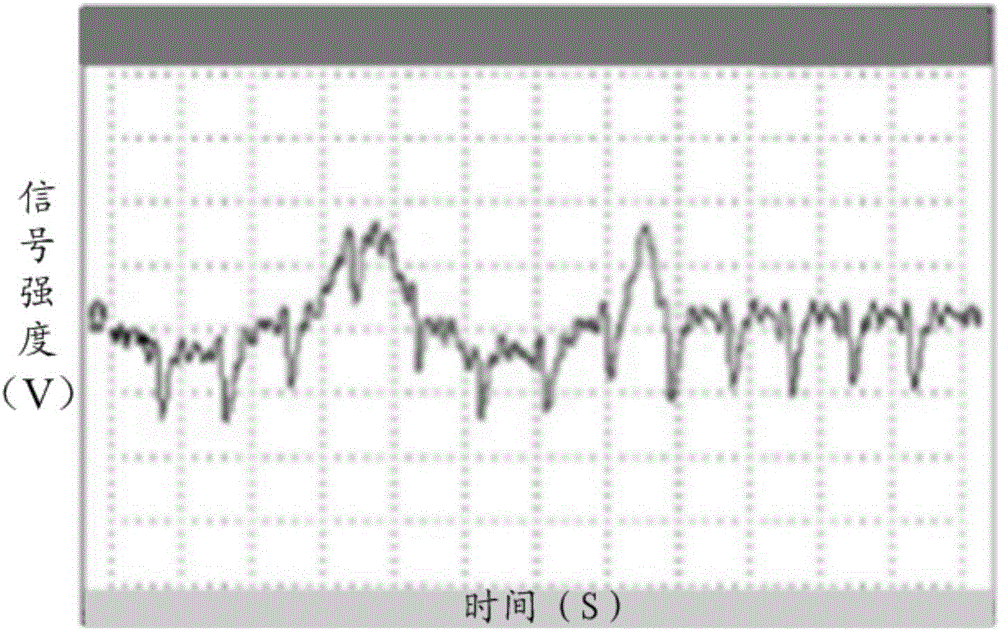

[0043]The tactile sensor based on the friction generator provided by the present invention includes: at least one friction generator, wherein the two opposite surfaces of the friction generator constitute a friction interface, and when an external force acts on the friction generator, the friction interfaces rub against each other, and the friction generator Output pressure electric signal corresponding to external force. Wherein, the tactile sensor based on the friction generator may include one friction generator, or may include multiple friction generators, which can be selected by those skilled in the art according to needs, which is not limited here. If the tactile sensor based on frictional generators includes multiple frictional gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com