Axial gap type rotation motor

A rotating electrical machine, axial gap technology, applied in synchronous motors with stationary armatures and rotating magnets, synchronous motors for single-phase current, electrical components, etc. , problems such as the reduction of the magnetic force of the permanent magnet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

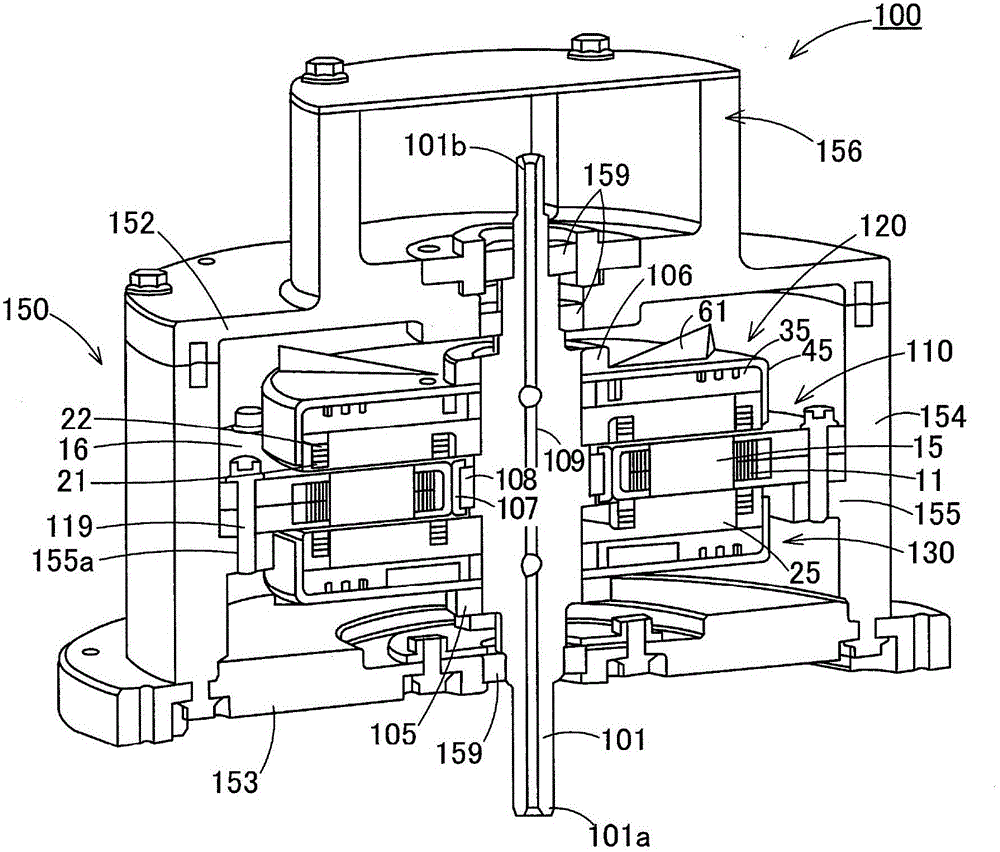

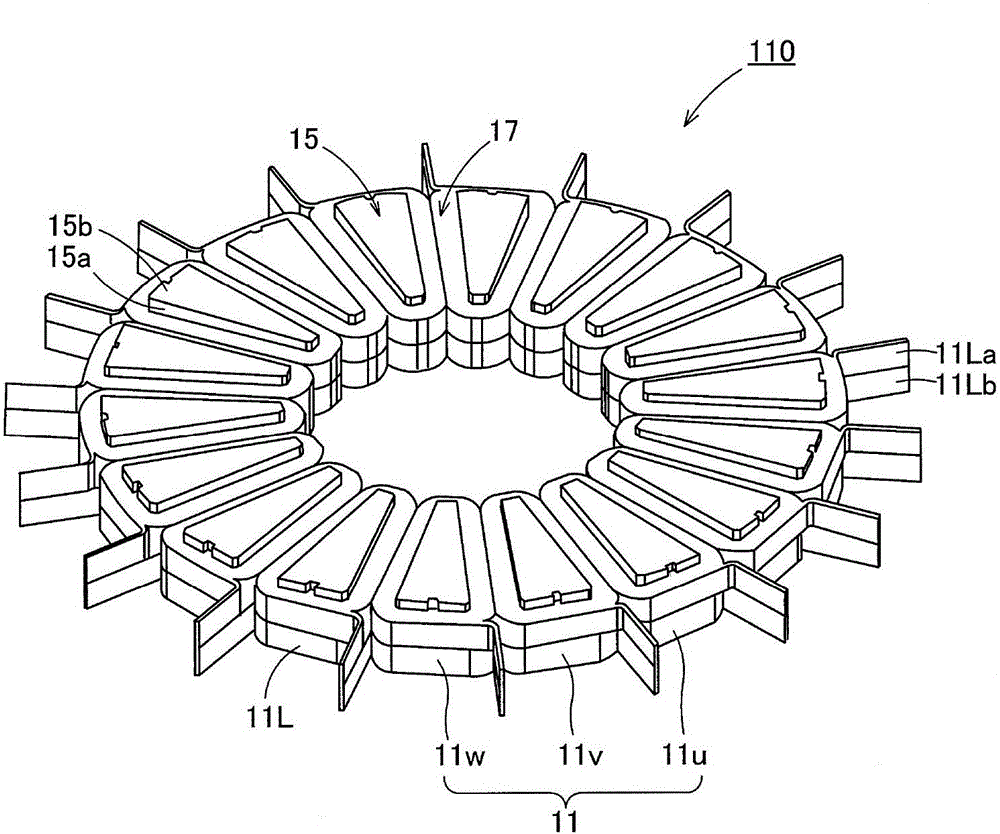

[0094] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. Figure 1 to Figure 27 It is a figure explaining the axial gap type electric rotating machine which is one embodiment of this invention.

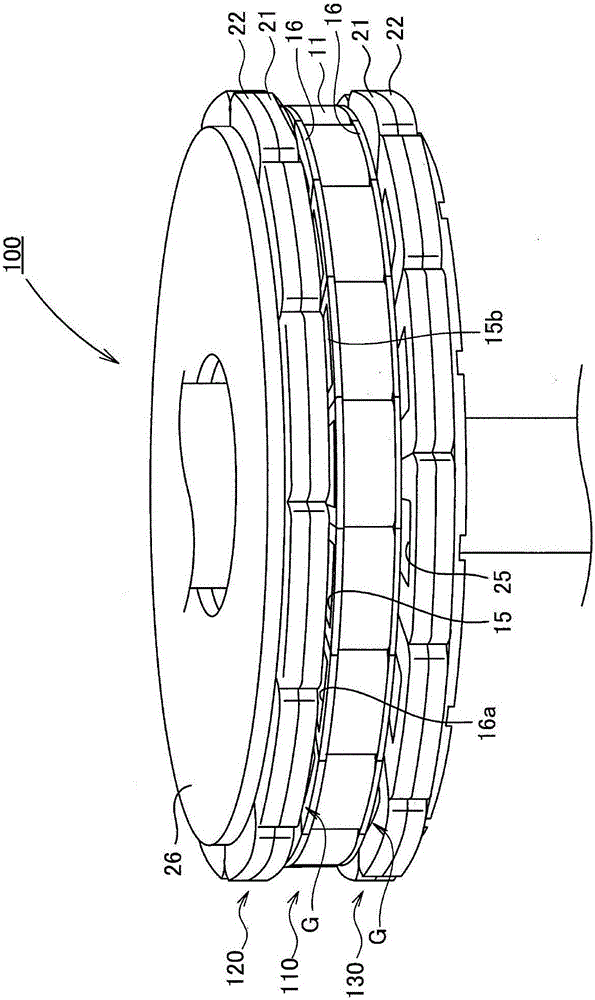

[0095] exist figure 1 and figure 2 Among them, the rotating electric machine 100 is provided with a stator 110 and two rotors 120 and 130 formed in a substantially disk shape, and as described later, there is no need to input energy to the rotors 120 and 130 from the outside by means of contact using slip rings or the like. The structure, for example, has performance suitable for being mounted on a hybrid vehicle or an electric vehicle.

[0096] In this rotating electric machine 100, two rotors 120, 130 are attached to a shaft (rotary shaft) 101 penetrating the shaft center, respectively, and are sandwiched by opposite sides of a stator 110 with a gap G therebetween. The stator 110 supports the shaft 101 so that It can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com