Contact support reaction spring installing structure and assembling method

A technology of reaction force spring and contact support, applied in the direction of detailed information of electromagnetic relays, relays, electrical components, etc., can solve the problems of difficulty in production, troublesome deburring of parts, high requirements for manufacturing precision and matching precision, and reduce the difficulty of production , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

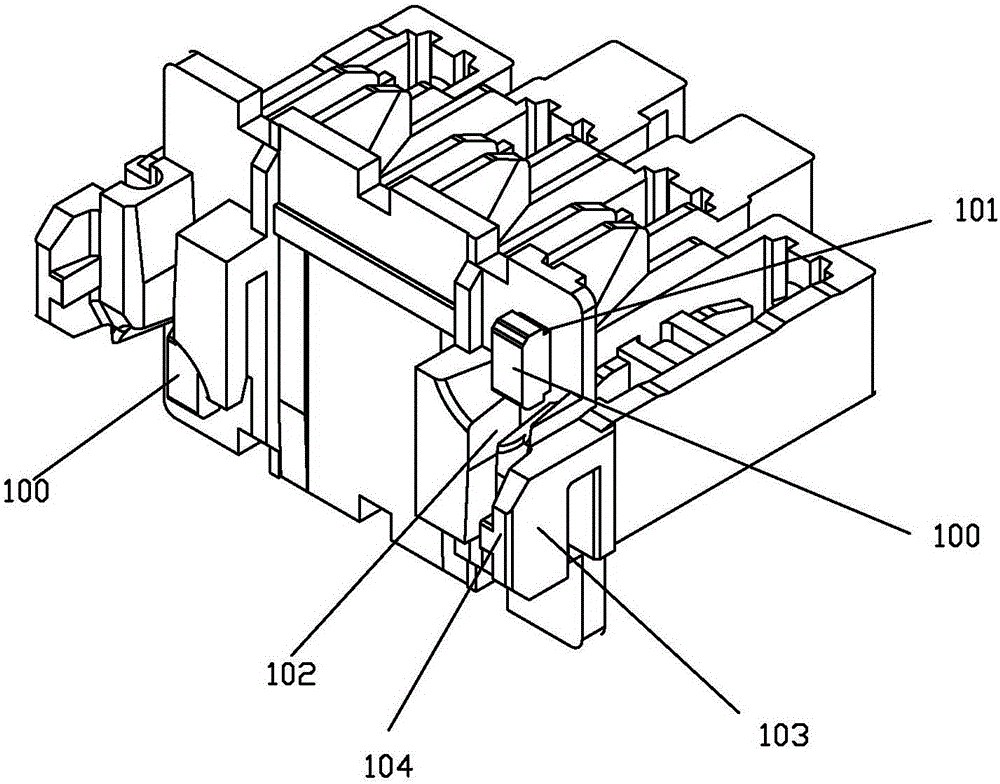

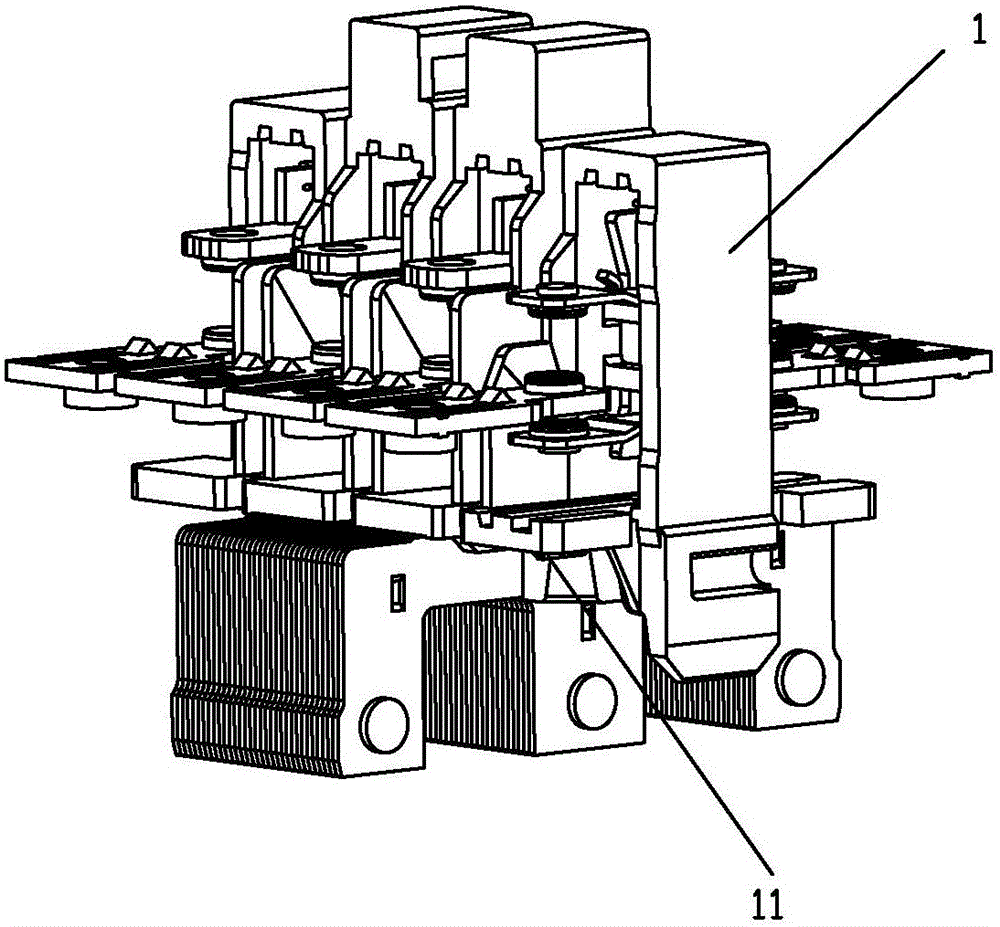

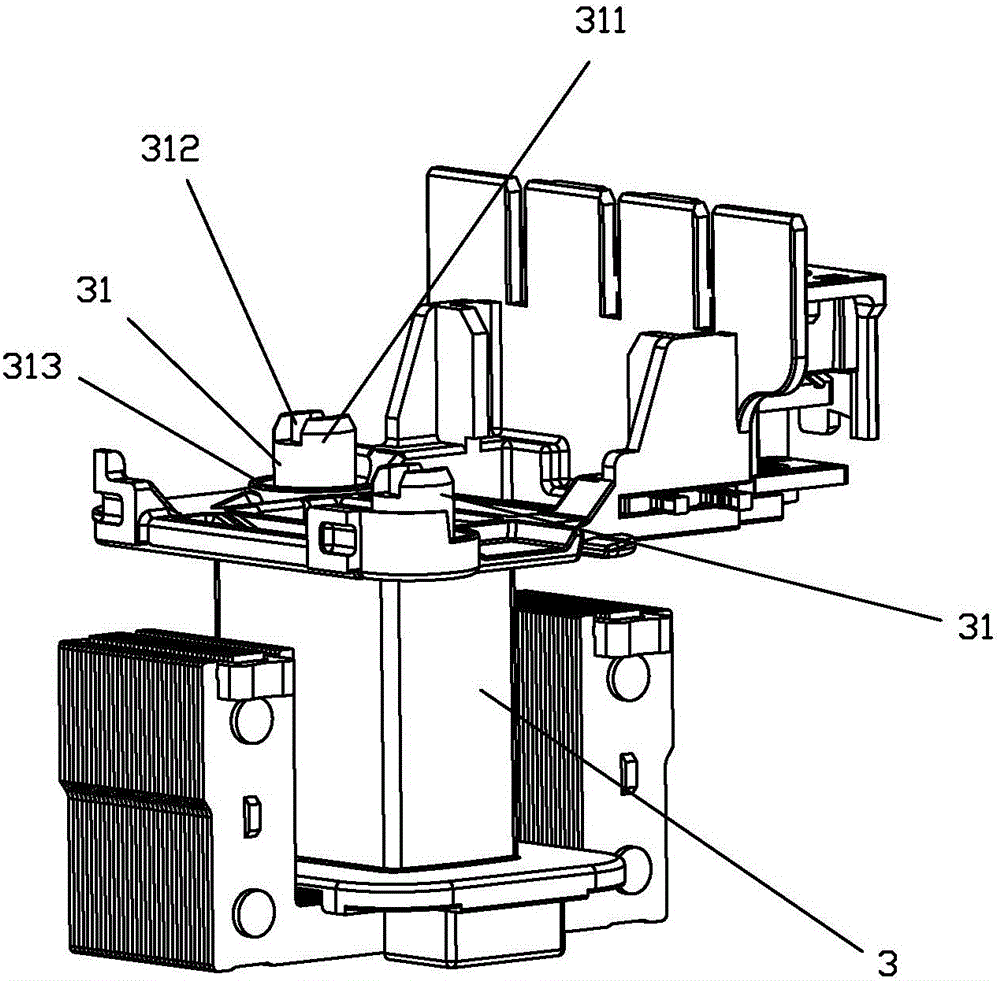

[0033] see Figure 2 to Figure 12 As shown, a contact support and reaction force spring installation structure of the present invention includes a contact support 1, a reaction force spring 2 and a coil frame 3; The first boss 11 of the bobbin 3 is provided with a second boss 31 used to match the other end of the reaction force spring 2; the protrusion of the second boss 31 has a raised portion 311, so that The reaction force spring can utilize the small gap of the mode of self free fall to be sleeved on the second boss 31 that has sufficient length and is convenient for guiding; When the first boss 11 supported by the contact overlaps with the second boss 31 of the bobbin due to being compressed, the avoidance portion 312 of the second boss forms an overlapping portion of the first boss 11 supported by the contact. Avoidance, so that the total stroke set by the contactor remains unchanged.

[0034] In this embodiment, the cross-section of the first boss 11 supported by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com