Hyperelasticity constitutive model modeling method of rubber material

A rubber material, constitutive model technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as molecular volume, topological constraints and non-affine deformation cannot be considered at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The accompanying drawings constituting a part of this application are used to provide further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

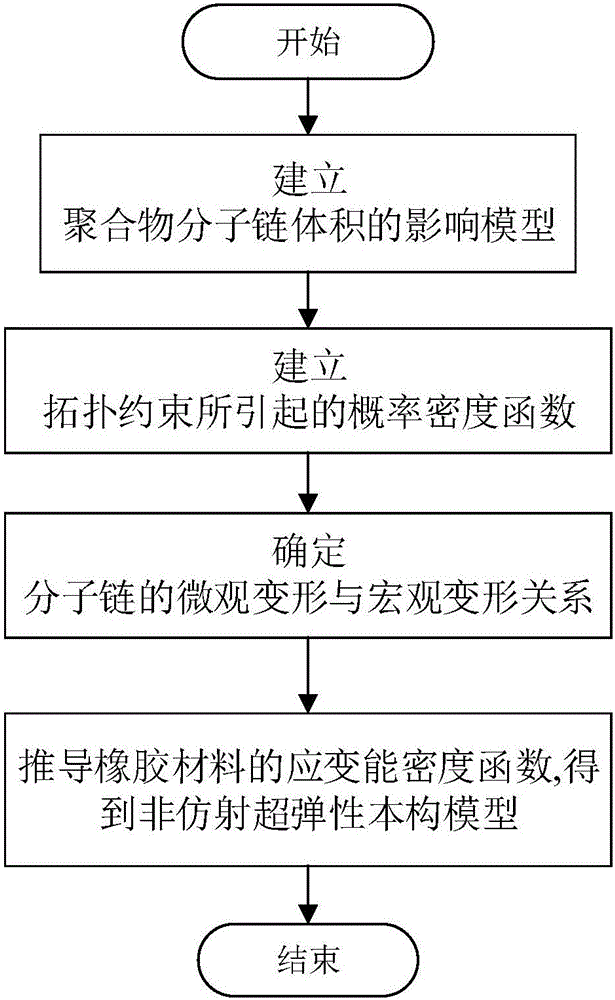

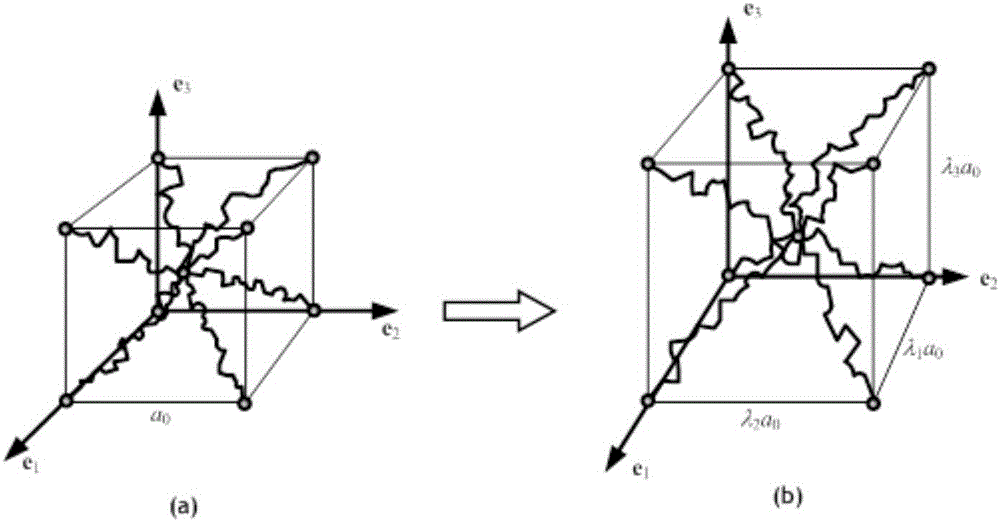

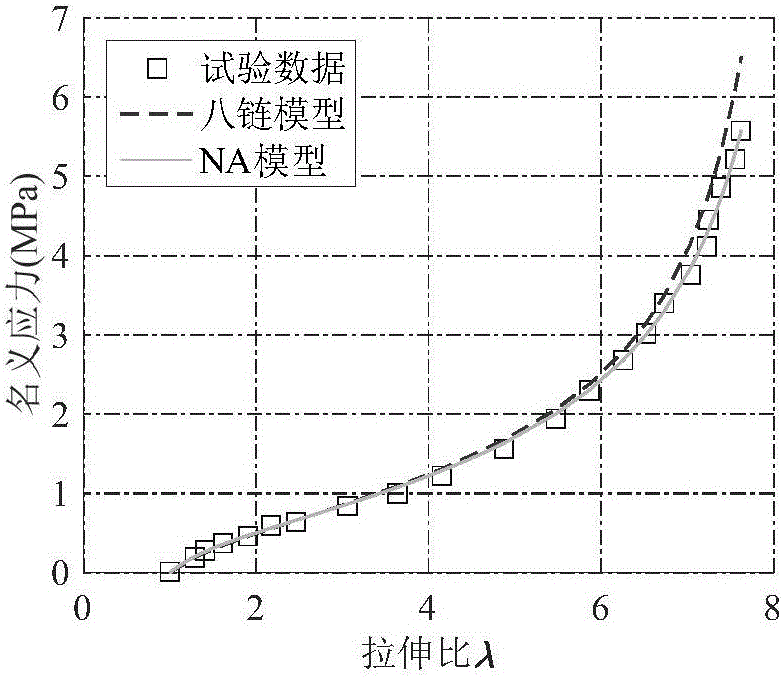

[0031] The rubber material hyperelastic constitutive model modeling method provided by the present invention considers the molecular volume, topological constraints and non-affine deformation of the rubber material hyperelastic constitutive relation modeling method at the same time, and establishes the non-affine hyperelastic constitutive model of the rubber material , hereinafter referred to as the NA (Non-Affine) model, the rubber material here can be various rubber materials, especially suitable for processing vinyl-terminated polydimethylsiloxane materials, which are elastic polymer silicone rubber materials , has strong machinability, and can be made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com