Electric window opening and locking system

An electric window opening and sash technology, which is applied in the field of doors and windows, can solve the problems of complex structure and high manufacturing cost, and achieve the effect of reliable structure, simple appearance, and smooth opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

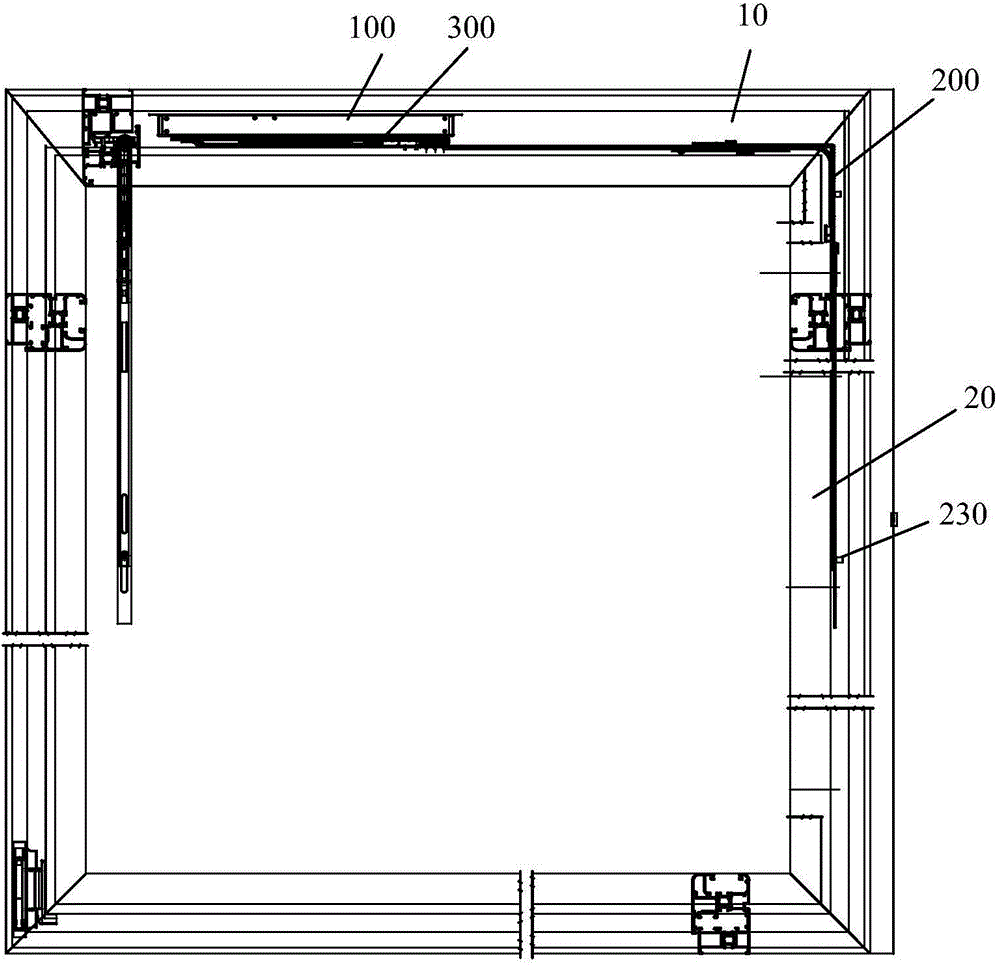

[0046] Such as figure 1 As shown, the electric window opening and locking system of the present invention includes an electric window opening machine 100 installed in the profile of the window frame 10, a window locking device 200 installed in the profile groove of the window sash 20, and a window lock device 200 installed in the profile groove of the window frame 10 and the window sash. There is a link mechanism 300 for pushing the window sash 20 to open and close.

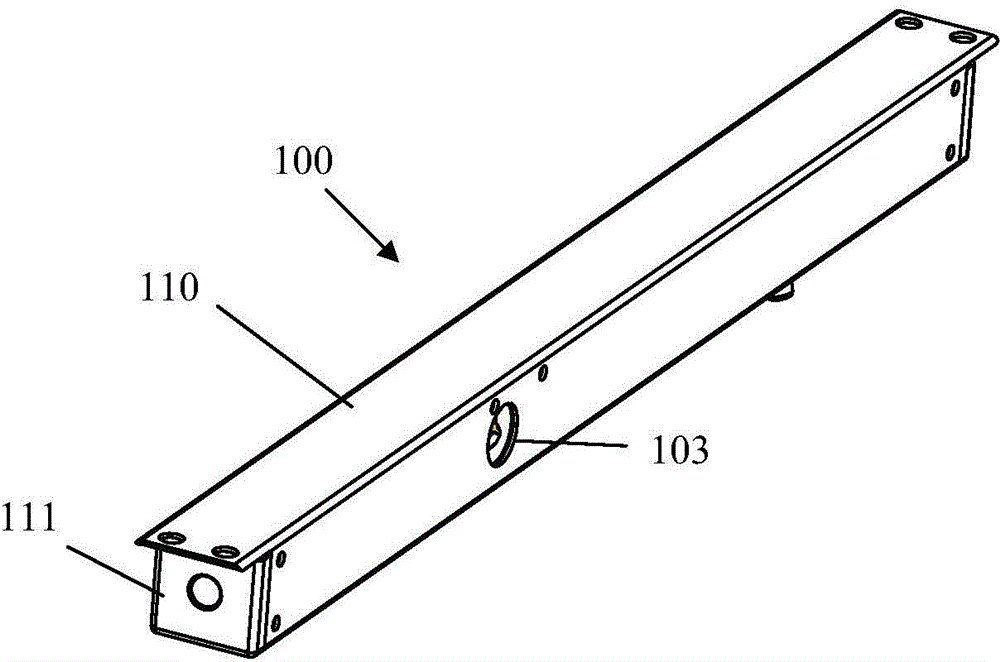

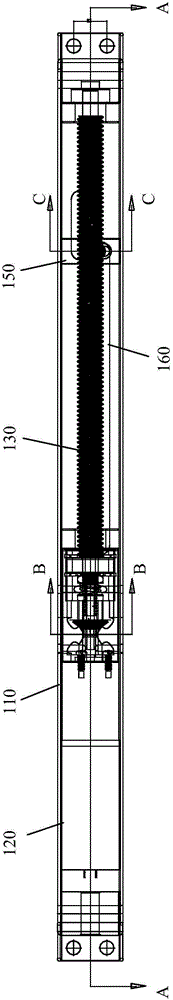

[0047] combine Figure 2-4 The electric window opener 100 shown includes a long aluminum alloy housing 110, with end covers 111 at both ends of the housing 110, and a detachable fastened housing cover 112 at the bottom. In the inner cavity of the housing 110 , a motor 120 is fixed at one end, and screw rods 130 distributed along the length direction of the housing 110 are provided at the other end. The screw rod 130 is supported by bearings 140 at both ends, and the screw rod 130 is covered with engaged nuts 15...

Embodiment 2

[0069] The electric window opening and locking system disclosed in Embodiment 2 is the same as Embodiment 1 except that the special-shaped guide slot 400 on the rail 310 is different from Embodiment 1.

[0070] See Figure 15 As shown, in the second embodiment, the rail 310 is also provided with a special-shaped long guide groove 400 , and the special-shaped long guide groove 400 is also composed of a first straight section 410 , a second straight section 420 and a transition section 430 . the difference is. The second straight section 420 is on the same straight line as the first straight section 410 , and the transition section 430 is a raised arched structure with two ends smoothly connected to the first straight section 410 and the second straight section 420 respectively.

[0071]In the second embodiment, the shape of the special-shaped long hole 160 on the cover of the electric window opener 100 is the same as the shape of the special-shaped long guide slot of this embo...

Embodiment 3

[0076] Such as Figure 16 and Figure 17 As shown, the difference between the present embodiment and the first embodiment is that the rail 300 is not provided with a self-locking mechanism, but a pushing block 700 is fixed on the top of the window sash 20 . The pushing block 700 is located below the yard 200, and is composed of a bottom plate 701 fixed on the window sash 20 and a baffle 702 protruding from the bottom plate 701. The inner side of the baffle 701 is a pressure rail surface 703, and the pressure rail surface 703 is a straight rail surface parallel to the second straight section 420, and the projection line of the pressure rail surface 703 on the yard 200 just passes through the second notch 502, preferably located near the bottom of the second notch. The lever 151 extends downwards below the upper surface of the baffle 702 to approach the bottom plate 701 . In this way, it can not only ensure that the driving rod 151 can enter the second notch 502 without being ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com