Shock absorber, washing machine and clothes dryer

A technology for shock absorbers and washing machines, which is applied to other washing machines, household dryers, washing devices, etc., can solve the problems of poor shock absorption effect of shock absorbers, easy aging of friction plates, and failure of damping of shock absorbers. Reduce the risk of shock absorption failure, reduce the risk of being worn, reduce the effect of rebound force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

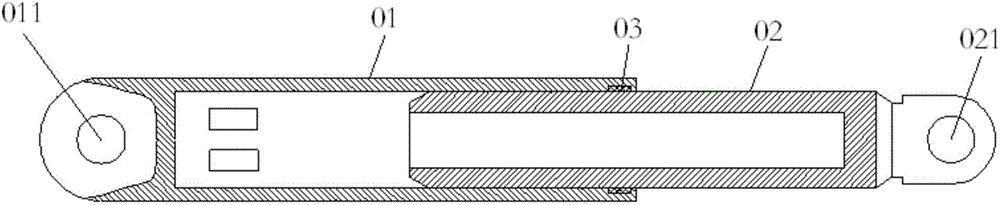

[0042] The drum washing machine provided by this solution includes at least one shock absorber, the shock absorber is located between the casing and the outer cylinder of the washing machine, and the two ends of the shock absorber are respectively connected with the casing and the outer cylinder. ,

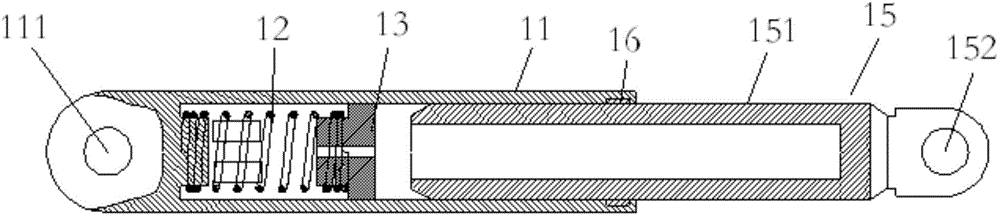

[0043] Specifically, such as figure 2As shown, the shock absorber mainly includes a damping guide sleeve 11 and a first friction sliding device 15 . One end of the sleeve 11 is provided with an opening, and the other end is a fixed end 111, and the fixed end 111 of the sleeve 11 is connected with the outer cylinder of the washing machine. The first friction sliding device 15 includes a first plunger 151, one end of the first plunger 151 is a fixed end 152, and the first plunger 151 is connected to the casing of the washing machine through the fixed end 152. The other end of the first plunger 151 can be inserted into the sleeve 11 through the opening of the sleeve 11 and can sli...

Embodiment 2

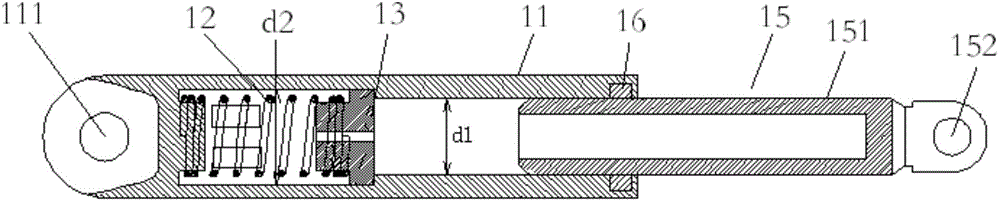

[0057] The difference from Embodiment 1 is that in this embodiment, if image 3 As shown, the sleeve 11 is divided into a first part of the sleeve and a second part of the sleeve, the second plunger 13 is located in the second part of the sleeve, and the friction plate 16 is located in the first part of the sleeve. The inner diameters of the first part of the sleeve and the second part of the sleeve are different, the inner diameter of the first part of the sleeve is d1, the inner diameter of the second part of the sleeve is d2, and the inner diameter of the first part of the sleeve is smaller than the inner diameter of the second part of the sleeve. Other than that, this embodiment is the same as the first embodiment, and will not be repeated here.

[0058] In this embodiment, the support member 12 can be deformed, but it is preferably a pre-compressed deformed support member 12, which can better absorb shock energy storage.

[0059] In this embodiment, since the inner diame...

Embodiment 3

[0063] Such as Figure 4 As shown, the same as the first embodiment, the sleeve 21 provided by this embodiment is fixed on the washing machine outer cylinder through the fixed end 211, the first plunger 251 is fixed on the washing machine box through the fixed end 252 at the end, and the sleeve 21 A friction plate 26 is provided at the opening. However, the difference between this embodiment and the first embodiment is that in this embodiment, both the support member 22 and the second friction sliding device are sleeved on the outside of the sleeve 21, and the second friction sliding device is a friction Ring 23. The first frictional sliding device 25 further includes an outer sleeve 253 disposed around the outer circumference of the first plunger 251 , the outer sleeve 253 is located outside the sleeve 21 and along the first plunger 251 . The inner wall of the sleeve 21 is in contact with the friction ring 23 when sliding to the inner side.

[0064] Preferably, there is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com