Method for preparing modified nano catalytic zinc oxide antimicrobial ceramic

A technology of nano-catalyst and antibacterial ceramics is applied in the field of preparation of modified nano-catalyst zinc oxide antibacterial ceramics, which can solve the problems such as difficult integration of inorganic antibacterial agent and ceramic base glaze, color distortion on the surface of antibacterial ceramics, poor durability, etc. Fast disinfection effect, good durability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

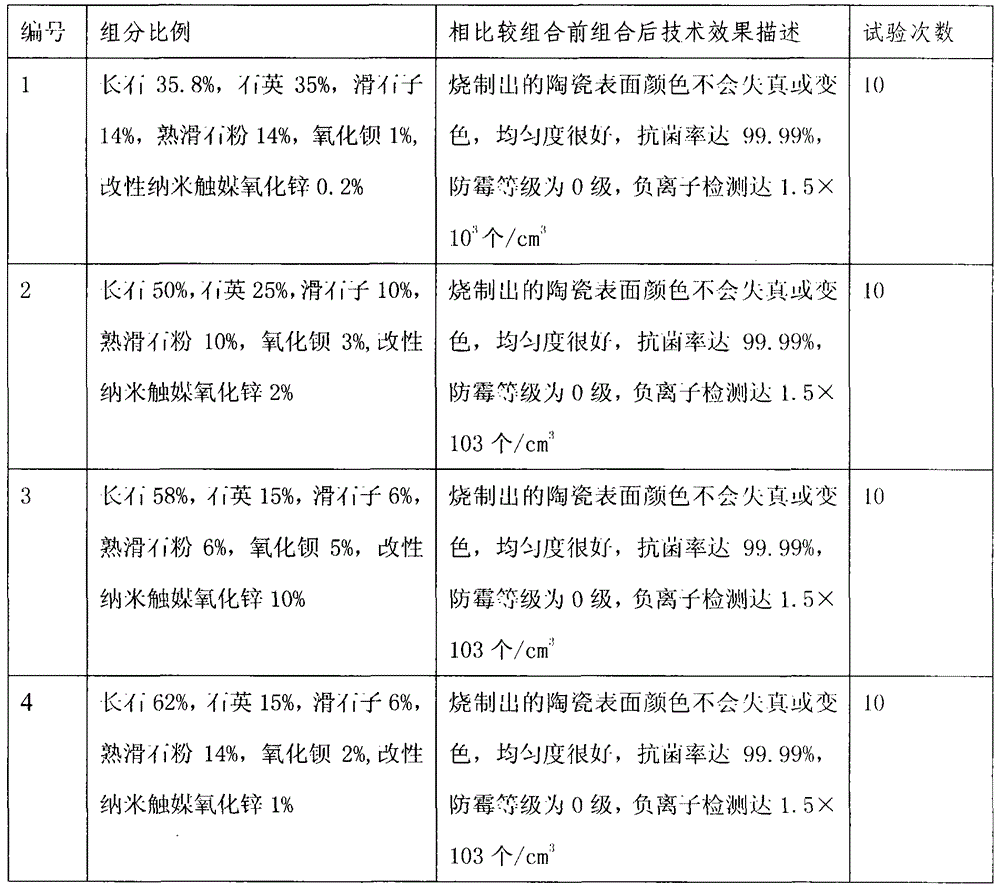

Examples

Embodiment 1

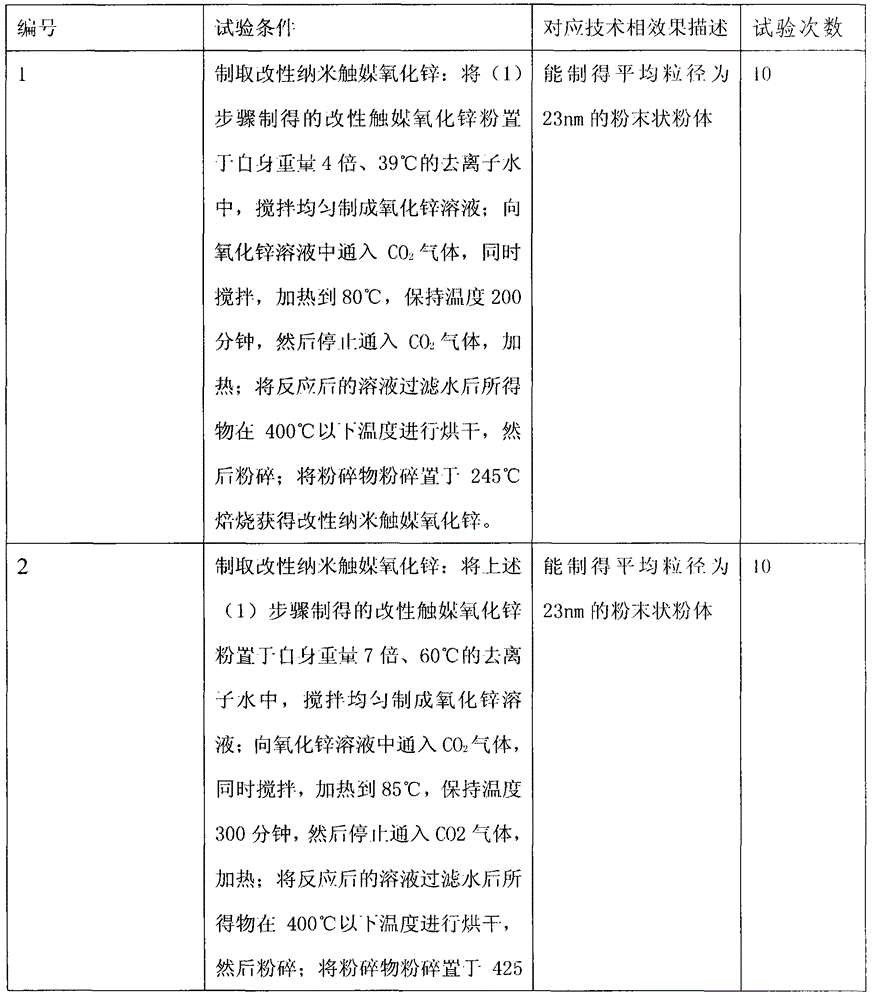

[0030] A preparation method of modified nano-catalyst zinc oxide antibacterial ceramics, comprising the following preparation steps:

[0031] (1) Preparation of modified catalyst zinc oxide powder: first, the catalyst zinc oxide is modified, and the modification method is to disperse the catalyst zinc oxide powder in isopropanol containing 2% polyoxyethylene sorbitan fatty acid ester In the process, through sand milling to achieve a single particle dispersion state, add tetraethoxysilane to the dispersion, keep the temperature of the system higher than 60 ° C and not boil, add water dropwise, stir and age for 5 minutes, cool to room temperature, filter, Rinse with deionized water until the conductivity of the filtrate is less than 8 μS / cm. After obtaining the filter cake, rinse with isopropanol, dry, pulverize and calcinate to obtain the modified catalyst zinc oxide powder with surface inorganic treatment;

[0032] (2) Prepare modified nano-catalyst zinc oxide: place the modif...

Embodiment 2

[0040] A preparation method of modified nano-catalyst zinc oxide antibacterial ceramics, comprising the following preparation steps:

[0041] (1) Preparation of modified catalyst zinc oxide powder: first, the catalyst zinc oxide is modified, and the modification method is to disperse the catalyst zinc oxide powder in isopropanol containing 2% polyoxyethylene sorbitan fatty acid ester In the process, through sand milling to achieve single particle dispersion state, add tetraethoxysilane to the dispersion liquid, keep the system temperature higher than 60°C without boiling, add water dropwise, stir and age for 12min, cool to room temperature, filter, Rinse with deionized water until the conductivity of the filtrate is less than 8 μS / cm. After obtaining the filter cake, rinse with isopropanol, dry, pulverize and calcinate to obtain the modified catalyst zinc oxide powder with surface inorganic treatment;

[0042] (2) Prepare modified nano-catalyst zinc oxide: place the modified cat...

Embodiment 3

[0050] A preparation method of modified nano-catalyst zinc oxide antibacterial ceramics, comprising the following preparation steps:

[0051] (1) Preparation of modified catalyst zinc oxide powder: first, the catalyst zinc oxide is modified, and the modification method is to disperse the catalyst zinc oxide powder in isopropanol containing 2% polyoxyethylene sorbitan fatty acid ester In the process, through sand milling to achieve a single particle dispersion state, add tetraethoxysilane to the dispersion, keep the system temperature higher than 60 ° C and not boil, add water dropwise, stir and age for 20 minutes, cool to room temperature, filter, Rinse with deionized water until the conductivity of the filtrate is less than 8 μS / cm. After obtaining the filter cake, rinse with isopropanol, dry, pulverize and calcinate to obtain the modified catalyst zinc oxide powder with surface inorganic treatment;

[0052] (2) Prepare modified nano-catalyst zinc oxide: place the modified ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com