Honeycomb-shaped activated coke for flue gas purification and production method thereof

A flue gas purification and activated coke technology, applied in the field of denitration activated coke and its preparation, and flue gas desulfurization, can solve the problems of large wind resistance, high fan power consumption, unfavorable promotion, etc. The effect of the floor area and the simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

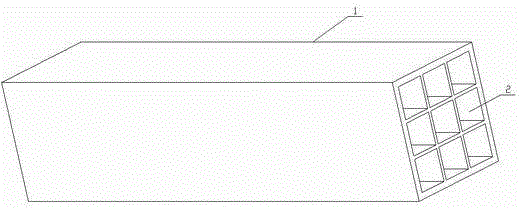

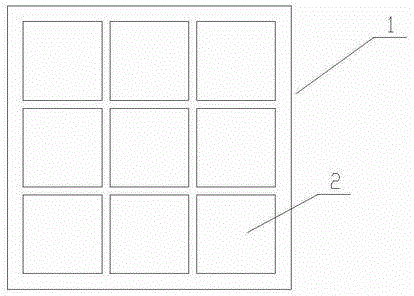

[0039] The following is attached Figure 1-2 An embodiment of the technical solution of the honeycomb activated coke for flue gas purification, which is the object of the present invention, will be described in detail.

[0040] Such as figure 1 As shown, the honeycomb activated coke for flue gas purification described in the technical solution of the present invention is a columnar body 1, such as figure 2 As shown, the cross-section of the columnar body 1 is square, and the interior is honeycomb-shaped. There are several flue gas channels 2 passing through the axial direction of the columnar body 1. The cross-sectional shape of the flue gas channel in this embodiment is square.

[0041] In practical application, the cross-section of the columnar body is rectangular, circular, regular hexagonal or other shapes. Preferably, the shapes and sizes of the several flue gas channels inside the columnar body are the same. The cross-sectional shape of the flue gas channel is pref...

Embodiment 2

[0045] Embodiment 2 is the first embodiment of the preparation method of honeycomb activated coke for flue gas purification according to the second object of the present invention.

[0046] In this embodiment, the production method of honeycomb activated coke for flue gas purification includes the following four steps:

[0047] Step (1): Batching and mixing: Based on the total mass of active coke powder and additives being 100%, the solid powder raw materials are configured according to the following mass fractions, active coke powder is 50-80%; additive powder is 20-50%. The solid powder raw material of the agent is mixed evenly until the powder material after mixing is uniform in color;

[0048]Step (2): Kneading: While constantly stirring the above powder materials, add water and monoethanolamine to knead the obtained mud materials so that the added liquid auxiliary materials and powder materials are fully contacted and mixed, and glass fibers are evenly added during the kn...

Embodiment 3

[0058] The third embodiment is the second embodiment of the preparation method of the honeycomb activated coke for flue gas purification according to the second objective of the present invention.

[0059] In this embodiment, the production method of honeycomb activated coke for flue gas purification includes the following four steps:

[0060] Step (1): Batching and mixing. Take 500g of active coke powder and 500g of pottery clay and fully mix until the color is uniform.

[0061] Step (2): Knead. Slowly add 80 ml of water to the above raw materials, and keep stirring and kneading for 30 minutes, slowly add 10 g of glass fiber, and continue kneading for 30 minutes to obtain the sludge to be extruded.

[0062] Step (3): extrusion molding. The sludge to be extruded is put into the extruder, and the honeycomb active coke wet body is obtained by forming through the basic die head.

[0063] Step (4): Drying. The above honeycomb activated coke wet body was dried in the shade at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com