Device with magnetic material for conveying object carriers for synchronizer component arranging table

A technology of magnetic materials and transportation devices, applied in transportation and packaging, conveyor control devices, conveyors, etc., can solve the problems of low detection and assembly efficiency, difficulty in ensuring detection and assembly accuracy, and high labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

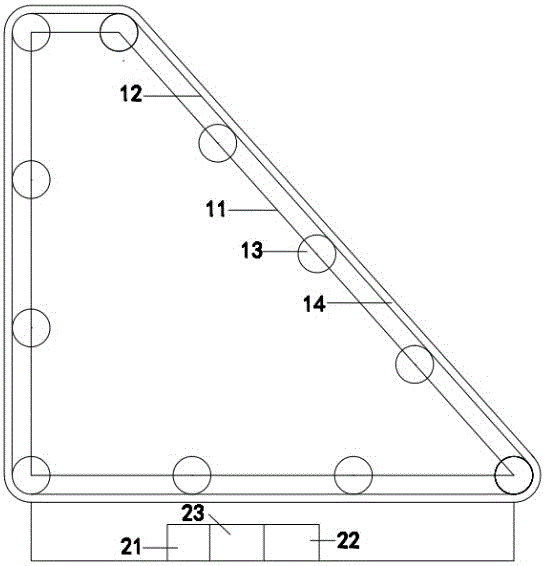

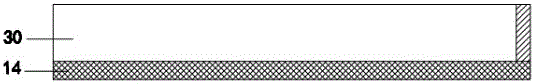

[0010] like figure 1 and figure 2 As shown, the synchronizer assembly material table carrier transport device with magnetic material provided by the present invention includes a support 11, two conveyor belts 12 and a control system; the support 11 is a prism whose side is a right-angled trapezoid; two The conveyor belt is installed on the periphery of the rectangular trapezoid on the side of the prism; the control system includes a motor 21, a signal receiver 22 and a processor 23; the motor 21 is connected to the conveyor belt 12; the motor 21 and the The signal receiver 22 is connected to the processor 23 ; each conveyor belt 12 is provided with a layer of magnetic material 14 .

[0011] Specifically, each conveyor belt 12 also includes several rollers 13; each of the rollers 13 is fixed on the bracket 11; each of the conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com