Aluminum-plastic composite trim strip

A technology of aluminum-plastic composite and decorative strips, applied in the field of decorative strips, can solve the problems of unsightly appearance, single surface color, lack of luster, etc., and achieve the effect of improving decorative effect, reducing cost, and not easily deformed or broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

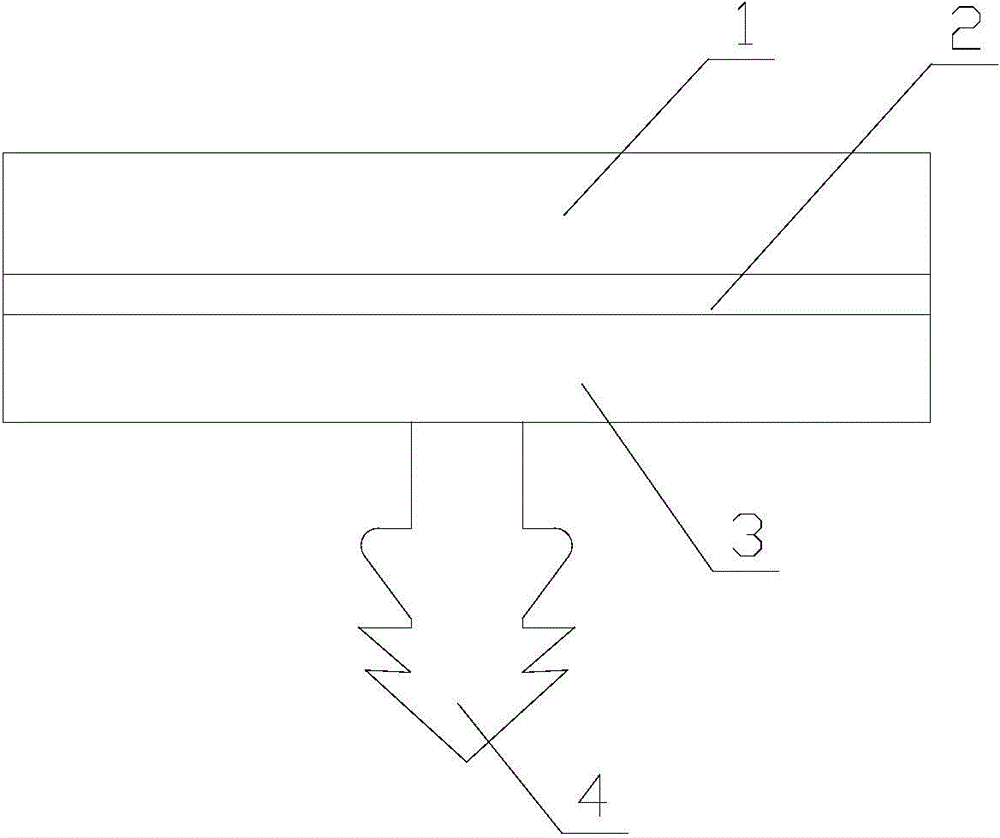

[0009] like figure 1 As shown, the aluminum-plastic composite decorative strip is composed of a transparent PVC plastic layer 1, an aluminum sheet 2 and an opaque plastic layer 3, the aluminum sheet 2 is arranged between the transparent PVC plastic layer 1 and the opaque plastic layer 3, and the opaque plastic layer 3 Be provided with reinforcing embedding rib 4, according to the different purposes of product, also can not be provided with embedding rib 4.

[0010] In an embodiment of the present invention, the opaque plastic layer 3 contains calcium carbonate, the content of calcium carbonate in the opaque plastic layer 3 can be between 5% and 70%, and the opaque plastic layer 3 contains PVC toughening agent, PVC The content of toughening agent can be between 1% and 60%, and the whole PVC plastic also contains 0.5% to 30% plasticizer, and its preferred value is 2%. The above specific values can be determined according to the strength and hardness requirements of the decorat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com