Rotor-stator structure of permanent magnet brushless DC motor

A DC motor, rotor stator technology, applied in the direction of magnetic circuit shape/style/structure, electric components, magnetic circuit, etc., can solve problems such as magnetic saturation, improve torque density and control accuracy, avoid tooth saturation, improve Effect of Winding Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

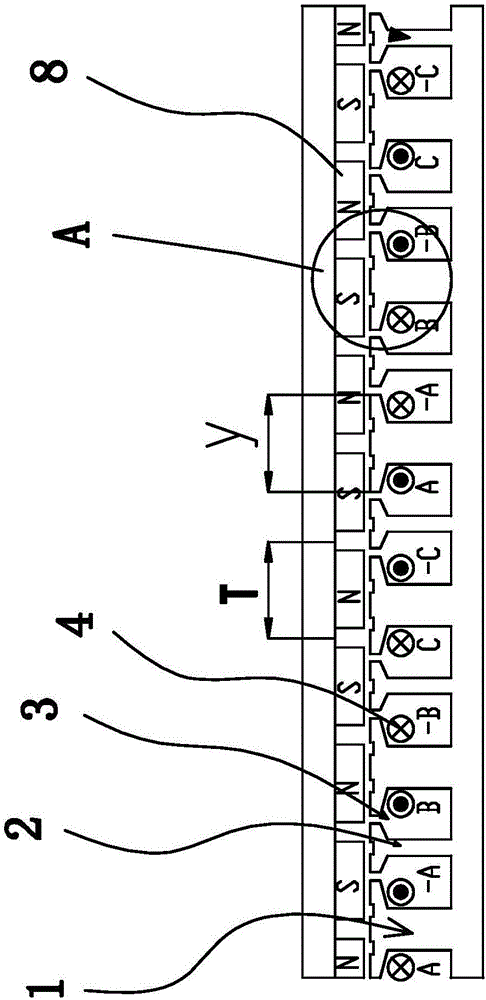

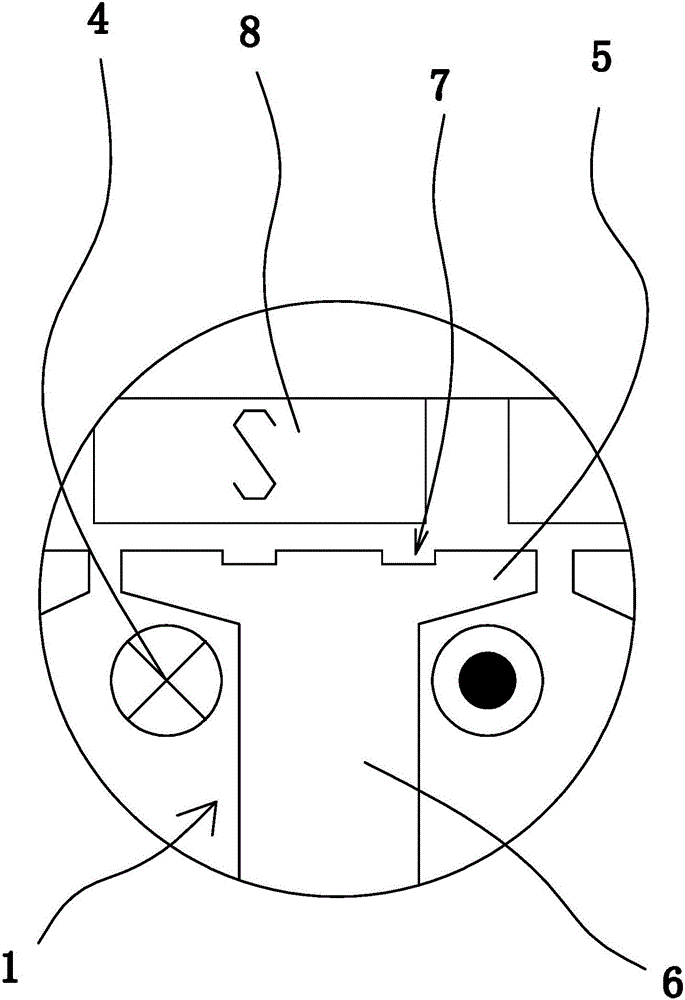

[0027] Such as figure 1 As shown, the rotor-stator structure of the permanent magnet brushless DC motor includes a stator and a rotor 8 , and the stator includes stator teeth, stator slots 3 and stator windings 4 .

[0028] Specifically, as figure 1 As shown, the stator teeth include several armature teeth 1 and several auxiliary teeth 2, the armature teeth 1 and the auxiliary teeth 2 both include tooth tops 5 and tooth parts 6, the width of the tooth tops 5 is greater than the width of the tooth parts 6, and the tooth parts 6 It is connected to the middle part of the bottom surface of the tooth top 5 and integrally formed. The tooth tops 5 and tooth parts 6 of the armature teeth 1 have widths greater than or smaller than the tooth tops 5 and tooth parts 6 of the auxiliary teeth 2. A number of armature teeth 1 and a number of auxiliary teeth 2 are spaced apart from each other in sequence, adjacent to each other. The stator slot 3 is formed between the armature tooth 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com