Screw mounting and detecting integrated equipment based on machine vision and operating method for screw mounting and detecting integrated equipment

A machine vision and screw technology, which is applied in the field of machine vision inspection of piano panel production, can solve problems such as inconvenient operation, affect work efficiency, and difficult positioning, and achieve the effect of convenient adjustment and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

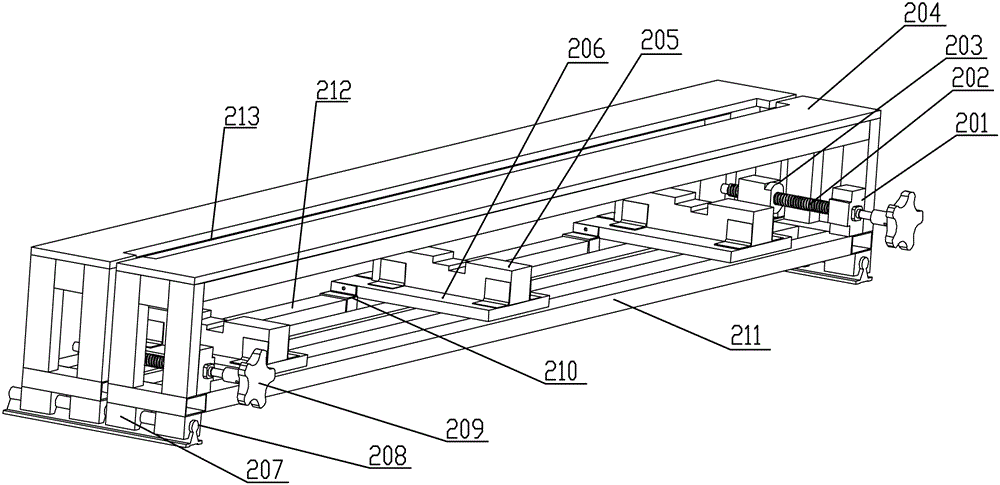

[0050] Such as Figure 1-4 As shown, the integrated equipment for screw installation and detection based on machine vision includes a frame 1. A clamping mechanism 2 is installed on the upper middle part of the frame 1, and the clamping mechanism 2 is installed on the frame 1 directly above A detection mechanism 3 is installed, and a screw mounting mechanism 4 is installed on the top of the rack 1, and the detection mechanism 3 is connected to an image capture card, and the image capture card is connected to an industrial control computer. The clamping mechanism is mainly used to clamp the front and rear piano top covers, the screw mounting mechanism is mainly used to install the screws of the piano top cover and hinges, and the detection mechanism is mainly used to detect whether the screw installation is qualified or whether it is missing.

[0051] Further, the frame 1 includes a lower frame 102 and an upper frame 105. The lower frame 102 is assembled and connected by profile co...

Embodiment 2

[0060] See Figure 5-6 , The operation method of connecting the piano top cover with the integrated installation and testing equipment includes the following steps:

[0061] S1: Turn on the power supply of the equipment and the industrial control computer. According to the model of the piano top cover, replace the modular block 205, and put two front top cover 7 and rear top cover 5 of different heights through the groove 213 of the clamping mechanism 2 and place them On the modular pad 205, keep the tops of the two top covers flush;

[0062] S2: Adjust the distance between the front clamp body 211 and the rear clamp body 212 by rotating the adjustment knob 209, and then adjust the gap between the front and rear piano top covers to reach the set gap;

[0063] S3: Place the hinge 6 in the groove on the top of the front top cover 7 and the rear top cover 5;

[0064] S4: Pull down the electric drill 404 to align the screw mounting holes on the hinge 6 for drilling operations, and then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com