Digital truck scale offset load error correction method based on least square method

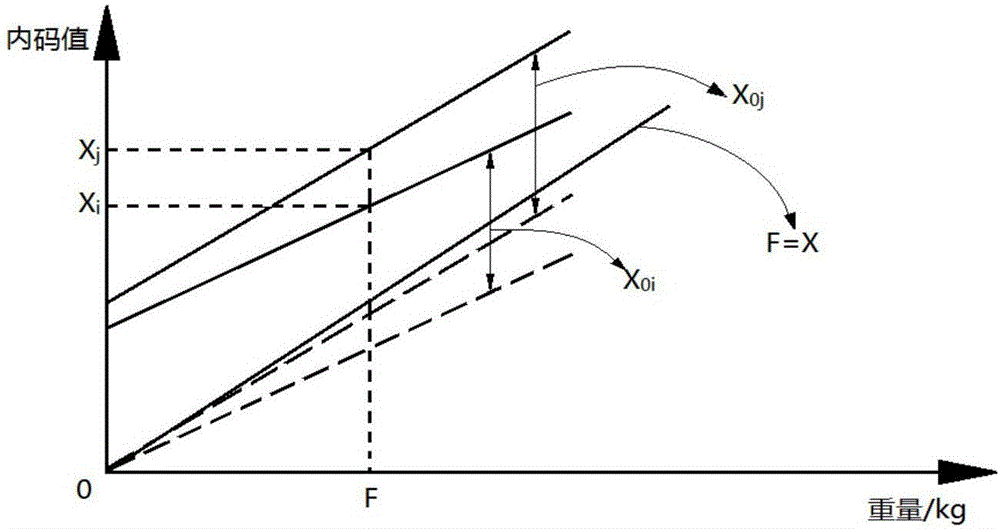

A technology of least squares method and eccentric load error, applied in the field of using the least squares method to correct the eccentric load error of truck scales, which can solve the problem that it is difficult to obtain the optimal angle difference coefficient, and the angle difference coefficient is not unique.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

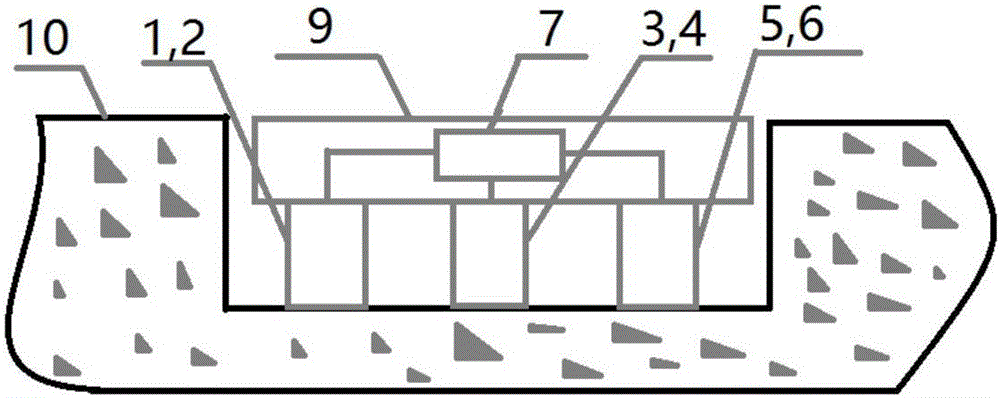

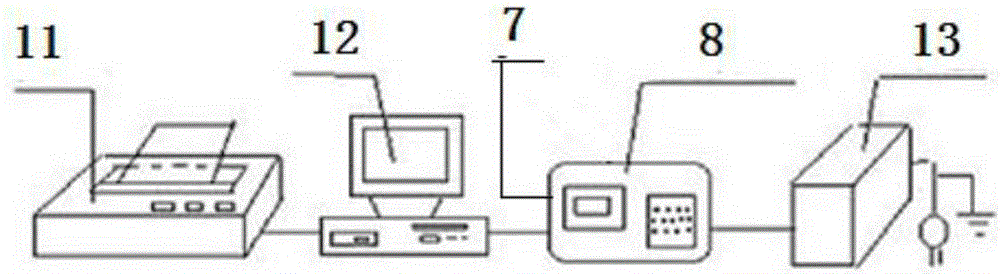

[0028] In order to test the accuracy of the results obtained by the linear equation, the experimental system is set up as figure 2 and image 3 shown. 6 digital weighing 1s are installed on the ground base 10 # Sensor 1, 2 # Sensor 2, ... 6 # sensor6. Scale body 9 is installed on these sensors, and these sensors all possess respective communication address, sensor position is set as Figure 4 As shown, the outer ring sensor is 1 # sensor 1, 2 # sensor 2, 5 # Sensors 5, 6 # Sensor 6, inner ring sensor is 3 # sensor 3, 4 # sensor4. Scale body 9 is long 12m, wide 3.2m. Connect the 6 sensors to the junction box 7 respectively, and then communicate with the controller 8 through the RS485 protocol. The controller 8 is connected to the microcomputer 12 through the data line, the microcomputer 12 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com