Leak detection method of thermal pipeline with insulation structure

A thermal pipeline and leakage detection technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems that the abnormal temperature change of the thermal pipeline cannot be found, and the specific location of the leakage point of the thermal pipeline cannot be determined, etc., to achieve The effects of reducing safety hazards and operational risks, high detection sensitivity and accuracy, and clear principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

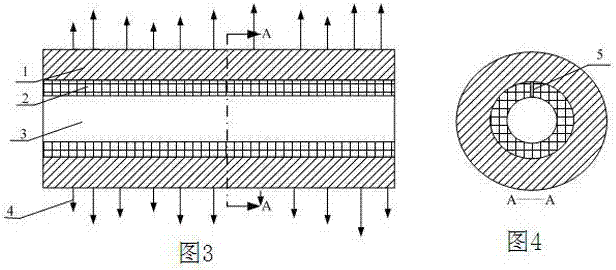

[0029] Example: as attached figure 1 , 2 , Shown in 3, 4, a kind of thermal pipeline leakage detection method with insulation structure, comprises the following steps:

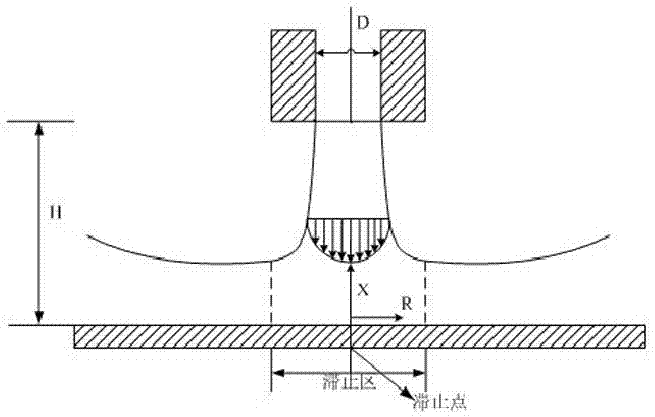

[0030] In the first step, the heat conduction and heat transfer process after the leakage of the heat pipe with thermal insulation structure includes the impact heat transfer of the pipe wall 2 slit jet flow and the heat conduction heat transfer of the insulation layer 1;

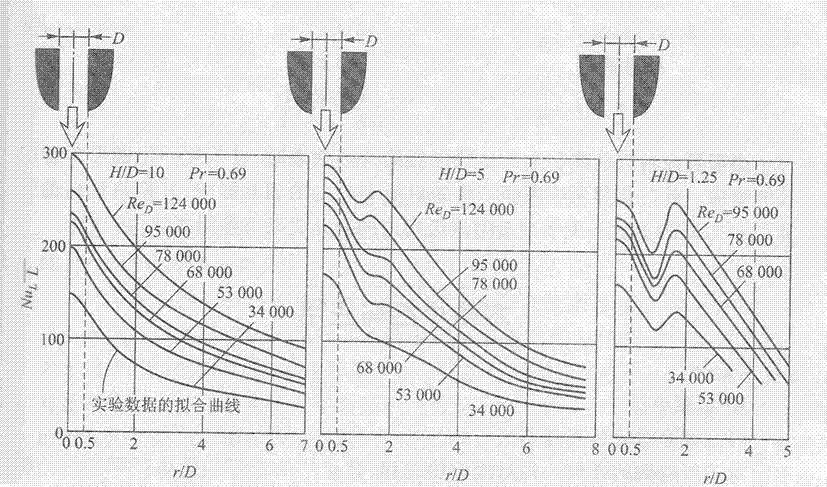

[0031] The second step is to analyze the flow field distribution formed by the impact jet on the impact surface of the pipe wall slit 5 nozzle. At the same time, according to the experimental data fitting, the Nu number when the relative distance between the pipe wall slit 5 nozzle surface and the impacted object is different is obtained. The distribution of the impact surface, that is, the distribution of the convective heat transfer coefficient of the impact jet of the pipe wall slit 5 nozzle at different distances from the impact surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com