Nuclear power steam cut-off control butterfly valve

A technology of steam and nuclear power, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of large opening torque, failure to provide, no solution given, etc., to achieve good heat dissipation, convenient adjustment, and avoid valve shaft stuck The effect of resistance or seal failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

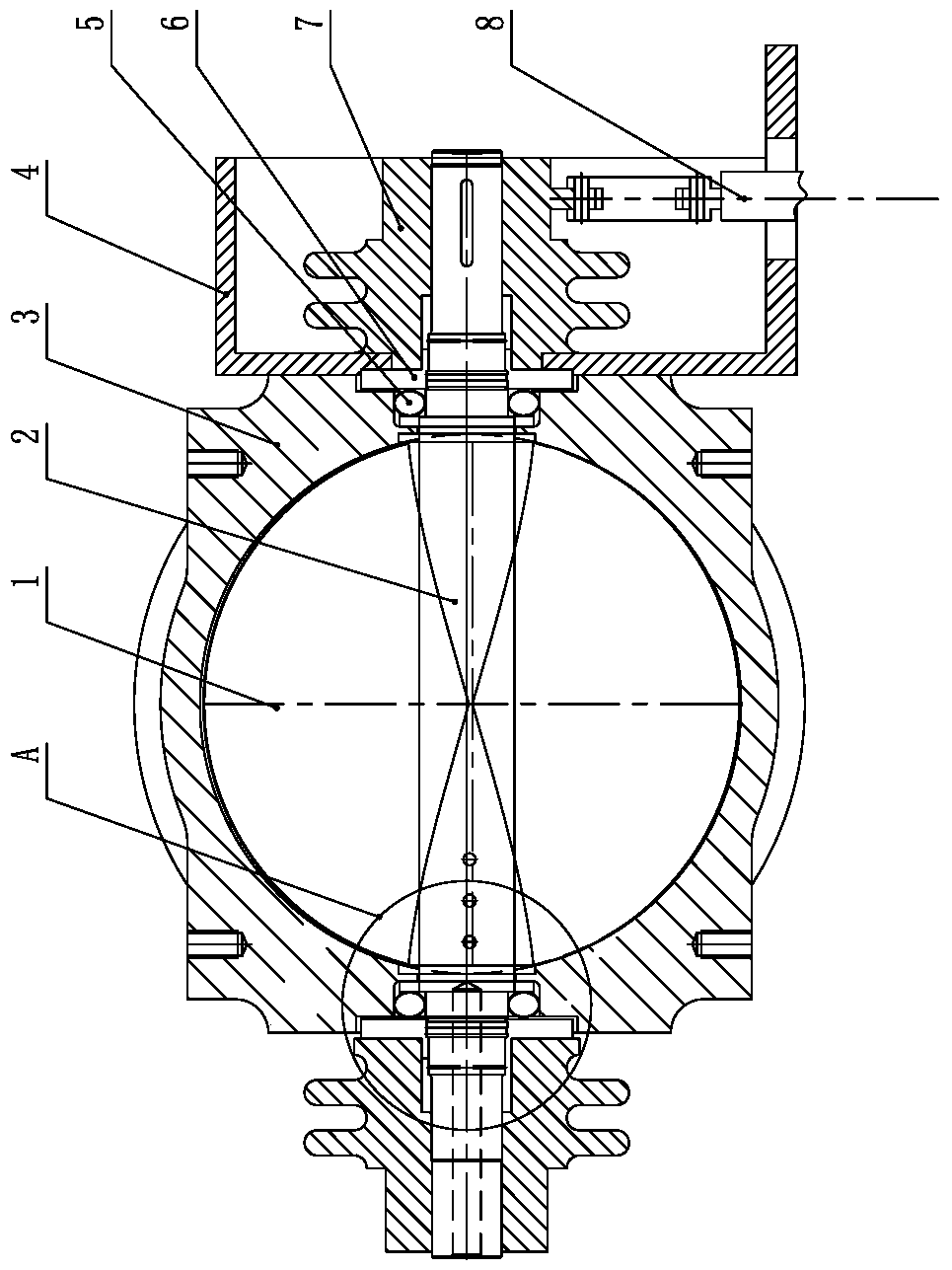

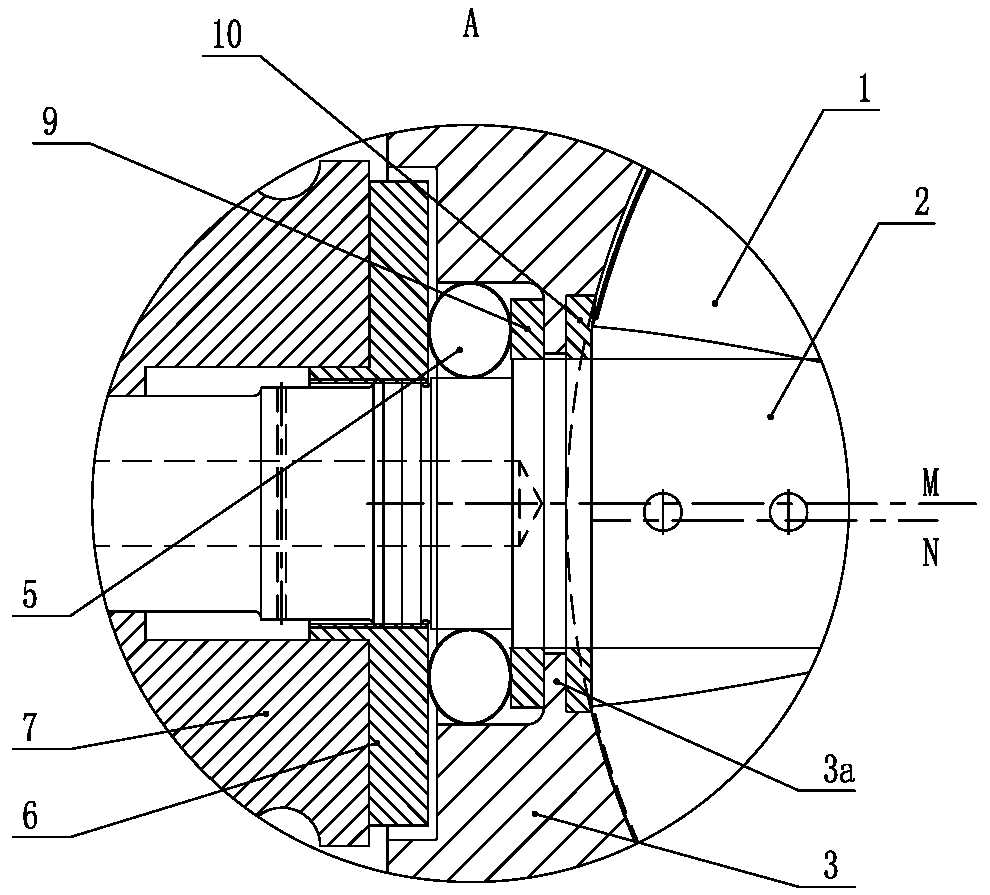

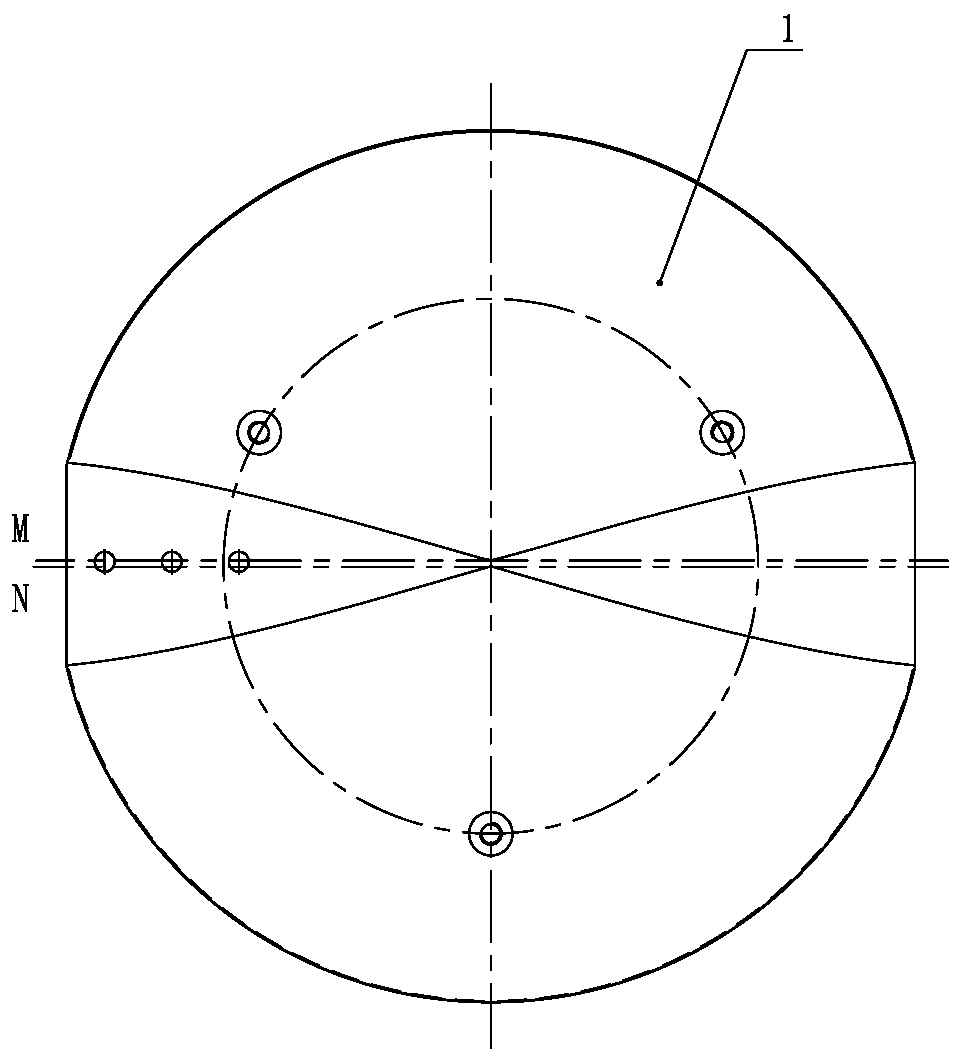

[0023] Such as Figure 1-2 As shown, it is a nuclear power steam cut-off control butterfly valve, including a valve body 3, a disc plate 1 and a valve shaft 2, the valve body 3 is connected to the bracket 4, and a circular valve cavity matching the disc plate 1 is provided inside the valve body 3. The disc 1 is in the shape of a round cake as a whole, and has a disc rotation axis P. The front and rear sides of the disc 1 are spherical; Installed in the valve cavity, both ends of the valve shaft 2 extend out of the valve body 3; the protruding end of the valve shaft 2 is fitted with a cooling seat 7, and the cooling seat 7 at one end is connected with a drive rod 8 that can drive the valve shaft 2 to rotate; The valve body 3 is provided with a mounting hole that can accommodate the valve shaft 2 to pass through with a gap, and a radial boss 3a is provided in the mounting hole; a shaft sealing device is provided between the valve shaft 2 and the valve body 3, and the shaft seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com