Paint high pressure filter safety relief valve

A pressure relief valve, high pressure technology, applied in safety valve, filter separation, balance valve and other directions, can solve the problem of limited application range of similar pressure relief valves, difficult to meet the use of paint, etc., to achieve a wide range of applications, pressure relief conditions Easy to adjust, good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

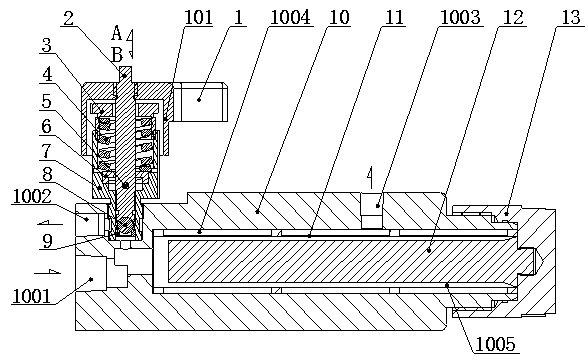

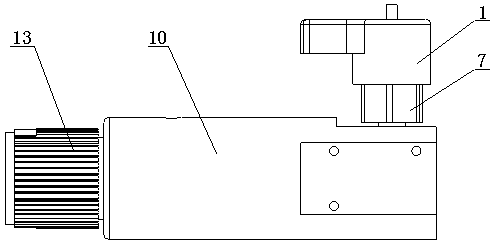

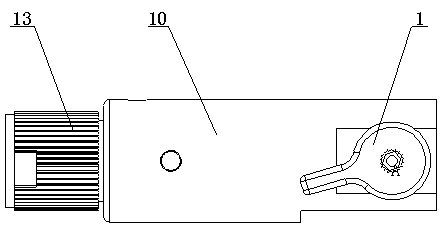

[0015] Now in conjunction with accompanying drawing, the present invention is described as follows.

[0016] Such as Figure 1-3 As shown, the paint high-pressure filter safety pressure relief valve is composed of a valve body part and a filter part.

[0017] The valve body part includes a handle 1, a valve stem 2, a compression nut 3, a spring 4, a linkage block 6, a valve sleeve 7, a valve, and a seal, and the valve is composed of a sealing valve head 8 and a valve seat 9. The specific structure is: the valve stem 2 is movably socketed with the compression nut 3, the spring 4, and the linkage block 6 from top to bottom; 4. The linkage block 6 is all placed in the valve sleeve 7, and is threadedly connected with the top of the valve sleeve 7 through the compression nut 3, so that the spring 4 and the linkage block 6 are compressed and limited in the valve sleeve 7. The valve rod 2 slides along the axial limit of the valve sleeve 7 and rotates relative to the valve sleeve 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com