Wheel-direction flow force movable plate pulling opening-closing flow plate vehicle and generation system

A technology of a power generation system and a movable panel is applied in the field of hydraulic wind power equipment, which can solve the problems of underutilization and unsatisfactory water power wind resources, and achieve the effects of strong damage resistance and low maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

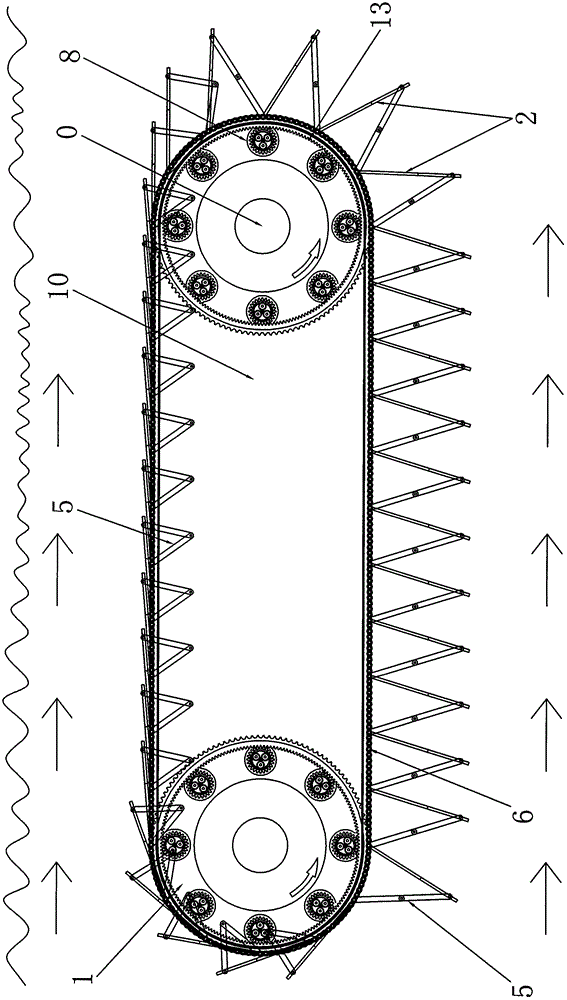

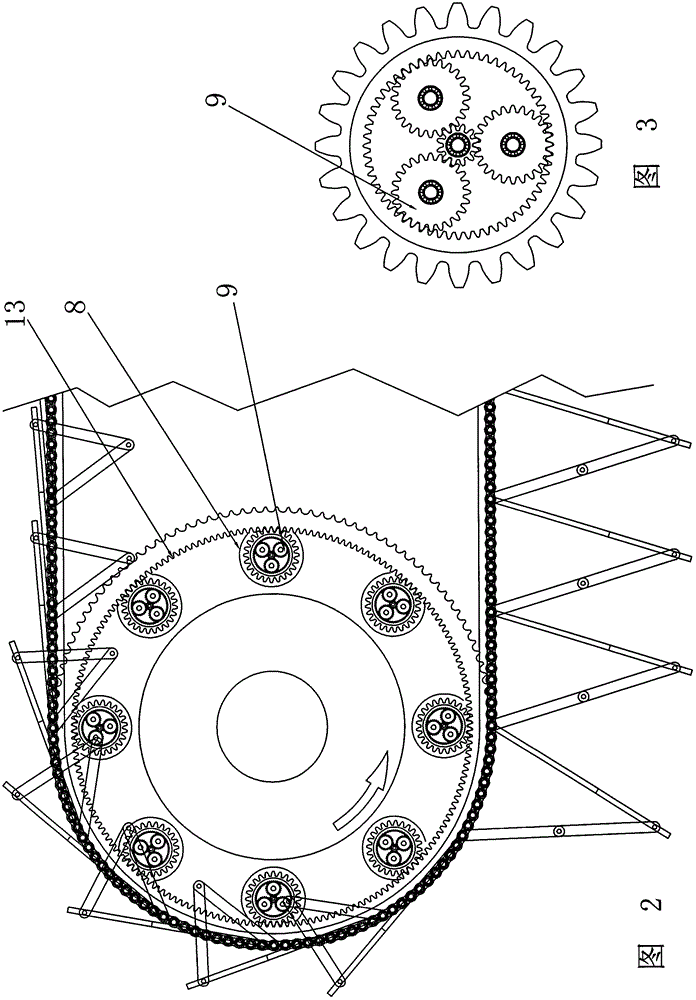

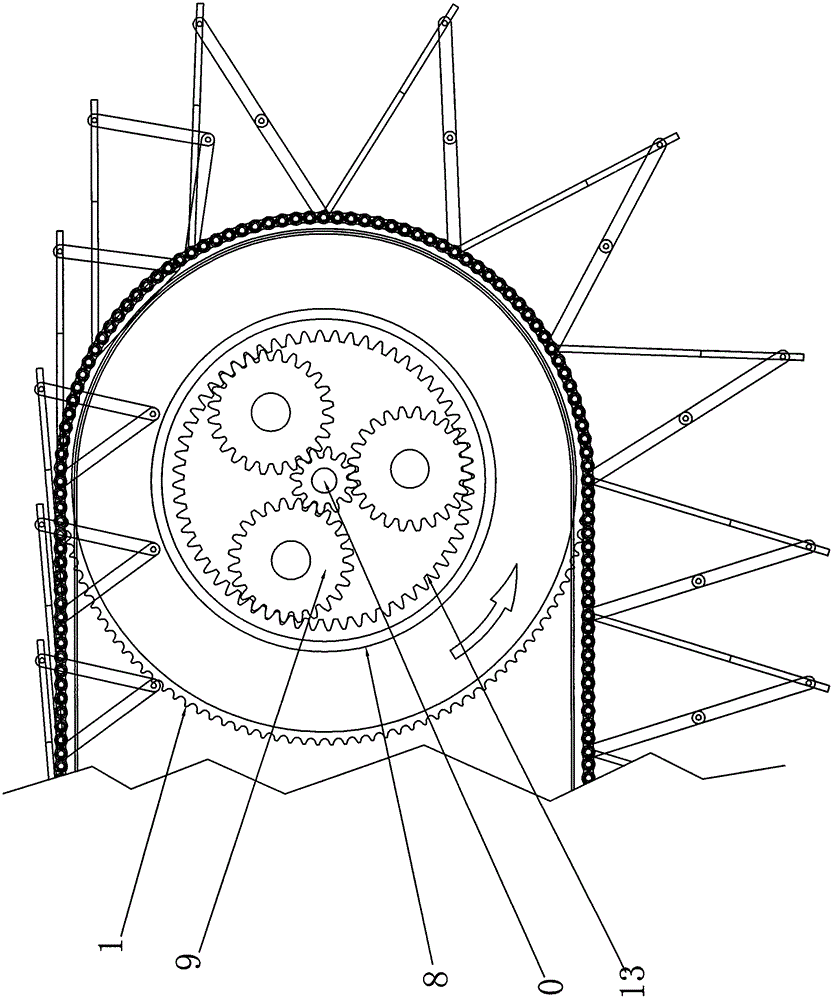

[0031] A kind of wheel direction flow movable board pulls and hangs the combined board car, such as figure 1 As shown, it includes: a runner 1, a central shaft 0, a movable plate 2, a hanging part 5, a chain belt 6 and a frame 10; 1 coaxial socket; said runners 1 are at least two, which are sprockets, gears or belt pulleys, and they rotate parallel to the two ends of the frame 10 with a central axis 0; said chain belt 6 links two rotating wheels Wheel 1; the plurality of movable plates 2 are hinged on the runners 1 at the two ends of the frame 10 in circular linkage with the chain belt 6, and its movable axis is parallel to the central axis O of the runner 1 or its movable axis is perpendicular to the rotating The central axis 0 of the wheel 1; the plurality of lifting parts 5 are hinged on the chain belt 6, one end of which is connected to the chain belt 6 and the other end is connected to the power end of the movable plate 2, and it is limited by the rated length of the hang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com