Composite bamboo floor and preparing method thereof

一种竹地板、地板的技术,应用在地板覆盖、化学仪器和方法、机械设备等方向,能够解决侵害、腐蚀、重组竹材料尺寸稳定性差等问题,达到生产成本降低、降低成本、浸胶和热压时间缩短的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

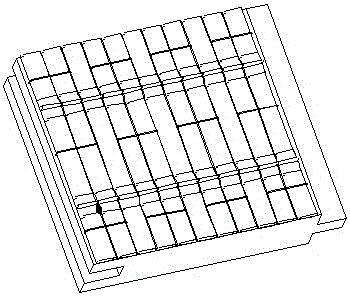

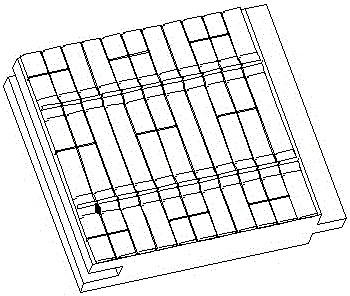

Image

Examples

Embodiment 1

[0081] The preparation method of composite bamboo floor comprises the following preparation steps:

[0082] (1) Floor panel prefabrication: Weave the bamboo fiber strip connector 02 with strength in the non-parallel direction of the bamboo fiber strip across the bamboo fiber strip 01 with a thickness of 1 mm and a width of 1 mm to form a bamboo fiber strip weaving curtain, and weave the bamboo fiber strip The woven curtain is impregnated with the first thermosetting resin to obtain a prefabricated floor panel; the width of the bamboo fiber strip woven curtain is 0.6-2m;

[0083] (2) Drying: Send the prefabricated board of the floor surface board to dry to a moisture content of 6%, and obtain a dry board of the floor surface board;

[0084] (3) Core board preparation;

[0085] (4) Hot pressing: Place the drying plate of the floor surface board on the top of the core board, and press it at a hot pressing pressure of 3Mpa / cm 2 170 DEG C of hot-pressing temperature is carried ou...

Embodiment 2

[0091] The preparation method of composite bamboo floor comprises the following preparation steps:

[0092] (1) Floor panel prefabrication: Weave the bamboo fiber strip connector 02 with strength in the non-parallel direction of the bamboo fiber strip across the bamboo fiber strip 01 with a thickness of 4mm and a width of 10mm to form a bamboo fiber strip weaving curtain, and weave the bamboo fiber strip The woven curtain is impregnated with the first thermosetting resin to obtain a prefabricated floor panel; the width of the bamboo fiber strip woven curtain is 2m;

[0093] (2) Drying: Send the prefabricated board of the floor surface board to dry until the moisture content is 10%, and obtain the drying board of the floor surface board;

[0094] (3) Core board preparation;

[0095] (4) Hot pressing: Place the drying plate of the floor surface board on the top of the core board, and press at a hot pressing pressure of 6Mpa / cm 2 1. Hot pressing at 120°C for a hot pressing time...

Embodiment 3

[0100] The preparation method of composite bamboo floor comprises the following preparation steps:

[0101](1) Floor panel prefabrication: Weave the bamboo fiber strip connector 02 with strength in the non-parallel direction of the bamboo fiber strip across the bamboo fiber strip 01 with a thickness of 2 mm and a width of 15 mm to form a bamboo fiber strip weaving curtain, and weave the bamboo fiber strip The woven curtain is impregnated with the first thermosetting resin to obtain a prefabricated floor panel; the width of the bamboo fiber strip woven curtain is 1.5m;

[0102] (2) Drying: Send the prefabricated board of the floor surface board to dry to a moisture content of 8%, and obtain a dry board of the floor surface board;

[0103] (3) Core board preparation;

[0104] (4) Hot pressing: Place the drying plate of the floor surface board on the top of the core board, and press the hot pressing pressure at 5Mpa / cm 2 140 DEG C of hot-pressing temperature are carried out hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com