Ecological slope protection method based on sludge solidification soil

A technology of ecological slope protection and solidified soil, which is applied in the field of ecological slope protection and ecological slope protection based on silt solidified soil, which can solve the problems of secondary pollution of soil and groundwater, high moisture content, space occupation, etc., and meet the needs of vegetation, high strength, and structure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

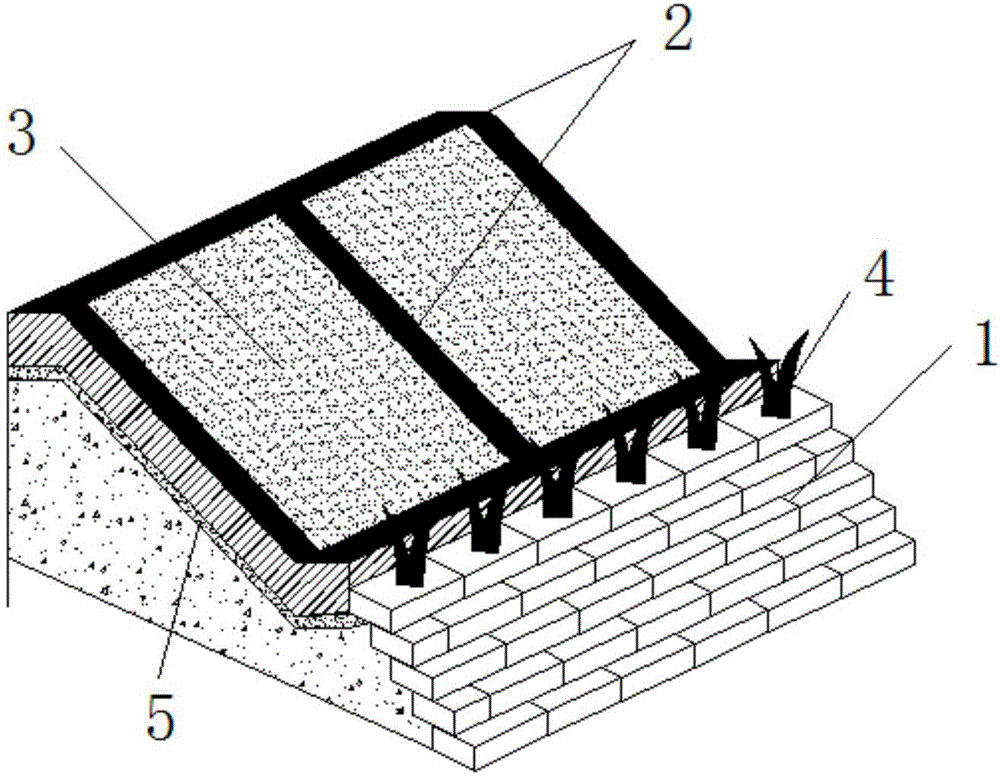

[0048] (1) Compact the slope surface and the bottom of the slope and repair it to make it level, keep the slope basically the same, and spread a layer of fine sand with a thickness of about 3cm;

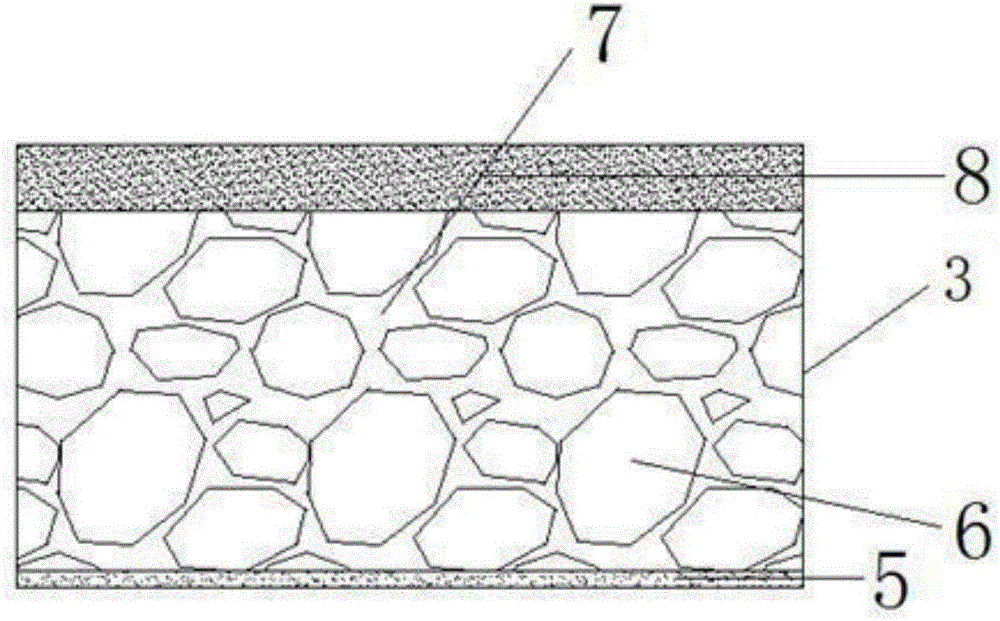

[0049] (2) Mix and stir the dredged bottom mud and the A component of the additional material evenly, and fill it into a vegetable bag with a length of 1.2m and a width of 0.5m. The A component is composed of dredging silt, fly ash, gypsum, organic fertilizer and soil It is made by mixing and stirring improved mineral materials, among which fly ash, gypsum, organic fertilizer and mineral materials account for 15%, 4%, 1% and 8% of the mixed mass respectively; the mineral materials are vermiculite powder, zeolite powder and expansive pearls rock, the mass ratio is 2:1:1;

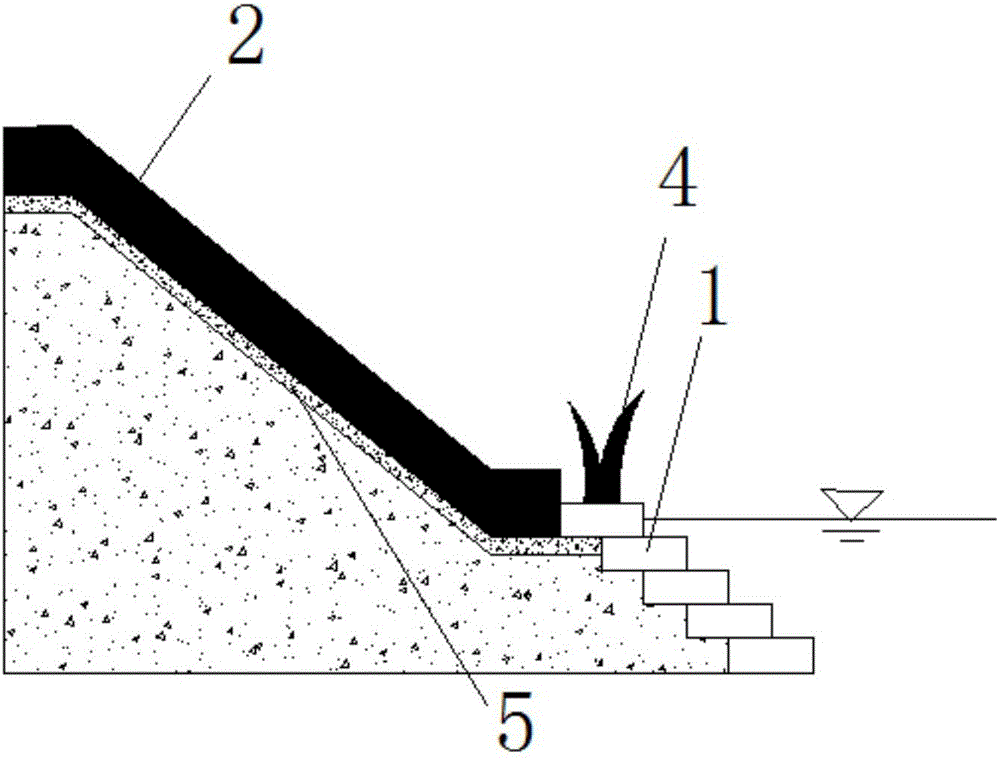

[0050] (3) Seal the filled vegetation bag and extrude it flat, measure and set off the line, place it in a stepped structure along the bottom of the slope to the slope surface layer by layer, lay 5 layers, and sow t...

Embodiment 2

[0064] (1) Compact the slope surface and the bottom of the slope and repair it to make it level, keep the slope basically the same, and spread a layer of fine sand with a thickness of about 3cm;

[0065] (2) Mix and stir the dredged bottom mud and the A component of the additional material evenly, and fill it into a vegetable bag with a length of 1.2m and a width of 0.5m. The A component is composed of dredging silt, fly ash, gypsum, organic fertilizer and soil The improved mineral materials are mixed and stirred, wherein the mass percentages of fly ash, gypsum, organic fertilizer and mineral materials are 20%, 3%, 3% and 4% respectively. The mineral materials are vermiculite powder, zeolite powder and expanded perlite, the mass ratio is 2:1:1;

[0066] (3) Seal the filled planting bag and squeeze it flat, measure and set off the line, layer by layer interlaced in a ladder structure and place it at the bottom of the slope protection slope, lay 5 layers, and sow tall fescue see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com