Special motor for circular weaving machine

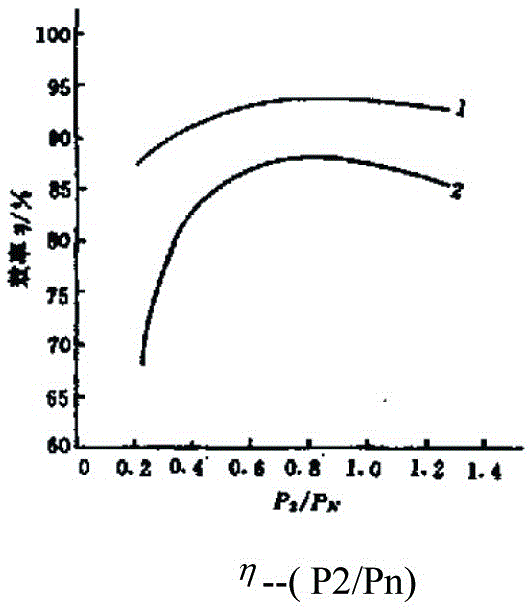

An electromechanical and circular weaving technology, which is applied in the field of motors of circular looms, can solve the problems of poor stability of control precision circular looms, poor efficiency and power factor, and low efficiency, so as to improve accuracy and timeliness, High energy saving effect and high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

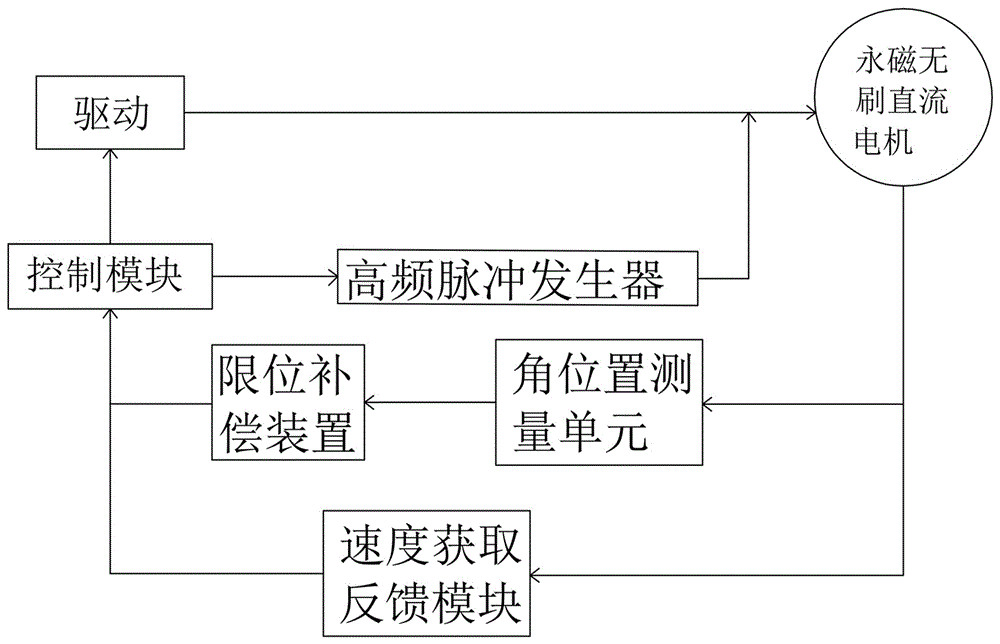

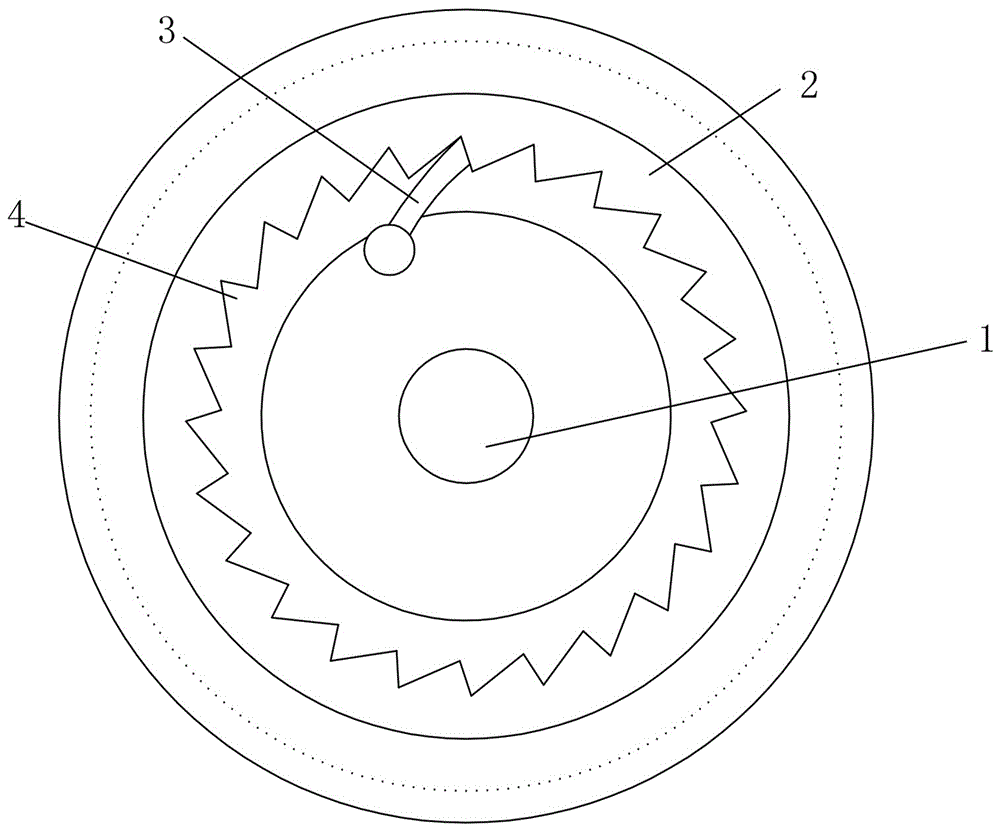

[0013] Such as figure 1 , figure 2 As shown, the present invention is dedicated to an embodiment of a circular loom motor, including a permanent magnet brushless DC motor or a permanent magnet synchronous motor, a permanent magnet brushless DC motor or a permanent magnet synchronous motor controller, and a transmission system of the motor. The permanent magnet brushless DC motor or permanent magnet synchronous motor controller includes a control module, an angular position measurement unit, a speed acquisition feedback module and an initial positioning module. The angular position measurement unit is used to measure the permanent magnet brushless DC motor or permanent magnet synchronous motor. The angular position signal of the stator and the rotor, the speed acquisition feedback module is used to output the real speed signal of the permanent magnet brushless DC motor or permanent magnet synchronous motor, and feed back to the control module: the control module adopts a progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com