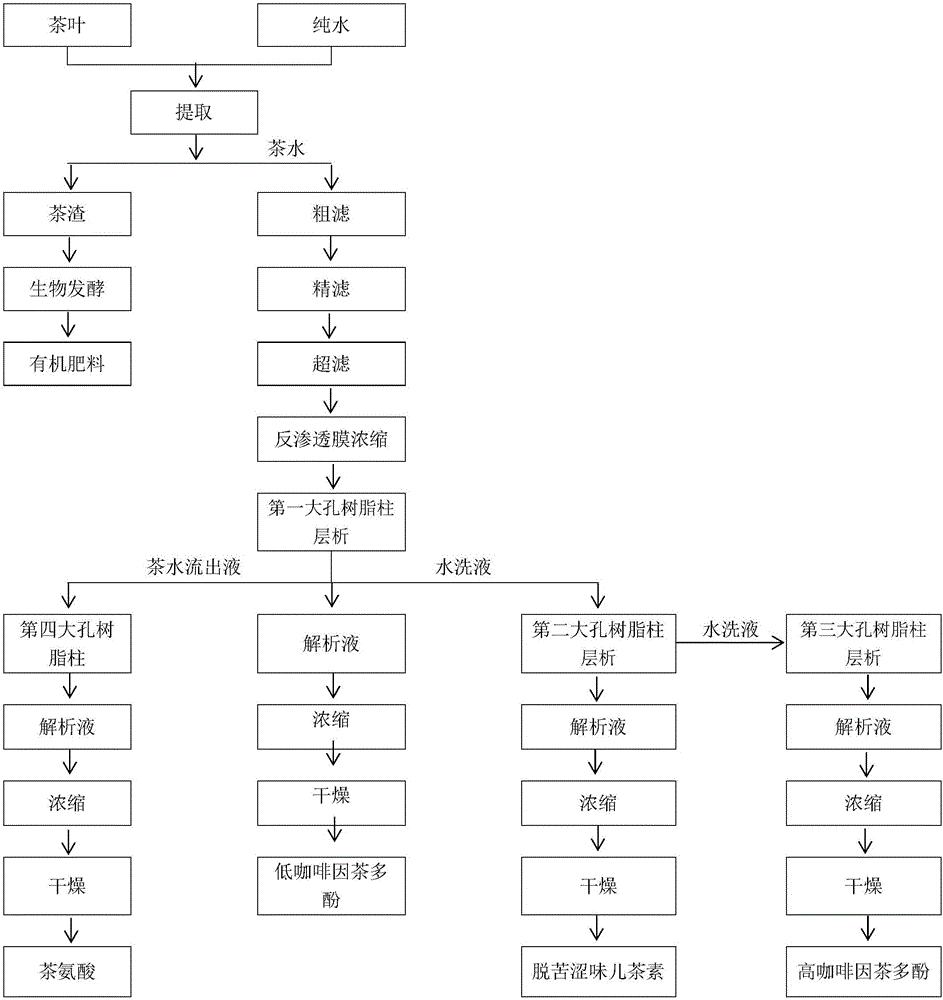

Tea polyphenol production process for producing plurality of products by one time of feeding

A technology for tea polyphenols and products, which is applied in the production process field of low-bitter catechins and high-caffeine tea polyphenols, can solve the problems of large equipment investment, unfavorable industrialized production, and high production costs, thereby reducing production costs. , the effect of improving the utilization rate of tea and improving the competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] For the first macroporous resin column, choose the resin model ADS-11, take 20L of tea concentrate, flow through the first macroporous resin column of 100×1000 at a flow rate of 1.2BV / H, and collect the effluent for later use. Then wash the impurities with 120L of 50°C pure water at a flow rate of 3BV / H, and collect the washing solution for later use. Finally desorb with 75% ethanol, the desorption amount is 1.5BV, the flow rate is 1BV / H, and the discharged desorption liquid is concentrated and dried in vacuum to obtain 340 grams of tea polyphenols, the content of tea polyphenols is 99.2%, the content of catechins is 80.1%, and the content of EGCG 60.5%, caffeine content 0.21%, product yield 6.8%.

[0038] The second macroporous resin column: resin model LX-8. Use the washing solution of the above-mentioned first macroporous resin column to load the column at a flow rate of 1.5BV / H; then wash the impurities with water at a washing volume of 3BV at a temperature of 40°C...

Embodiment 2

[0043] The first macroporous resin column, choose the resin model ADS-8, take 20L of clear tea concentrate, pass through the first macroporous resin column of 100×1000 at a flow rate of 1.5BV / H, collect the effluent for later use, and then use 100L Wash the impurities with pure water at 45°C, collect the washing liquid for later use, and finally use 75% ethanol for desorption, the desorption volume is 1.5BV, the flow rate is 1BV / H, the desorption liquid is collected, concentrated and dried in vacuum to obtain 325 grams of product, the content of tea polyphenols is 99.5% , the catechin content is 81.6%, the EGCG content is 62.3%, the caffeine content is 0.12%, and the product yield is 6.5%.

[0044] The second macroporous resin column: choose the resin model HPD200, use the washing liquid of the first macroporous resin column to load the column, the flow rate is 1.5BV / H, and then wash the impurities with pure water, the temperature of pure water is 40°C, the washing volume is 4B...

Embodiment 3

[0049] The first macroporous resin column, choose the resin model SAD-11, take 20L of clear tea concentrate, pass through the first macroporous resin column of 100×1000 at a flow rate of 1.2BV / H, collect the effluent for later use, and then use 100L Wash the impurity with pure water at 50°C, collect the washing liquid for later use, and finally use 80% ethanol for desorption, the desorption volume is 1.5BV, the flow rate is 1.2BV / H, the desorption liquid is collected, concentrated and dried in vacuum, and 330 grams of the product are obtained, the content of tea polyphenols is 99.2 %, the catechin content is 80.6%, the EGCG content is 59.8%, the caffeine content is 0.58%, and the product yield is 6.6%.

[0050] The second macroporous resin column: choose the resin model SP20, use the washing solution of the first macroporous resin column to load the column, the flow rate is 1.2BV / H, and then wash the impurities with pure water, the temperature of pure water is 45°C, the washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com